Scroll braking device of full-automatic steel bar strapping machine and same

A braking device, fully automatic technology, applied in the processing of building materials, construction, building structure and other directions, can solve the problems of wire scattered, affecting wire feeding, wire reel stuck, etc., to achieve fast response speed and prolong battery life , reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the application or uses of the present disclosure. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

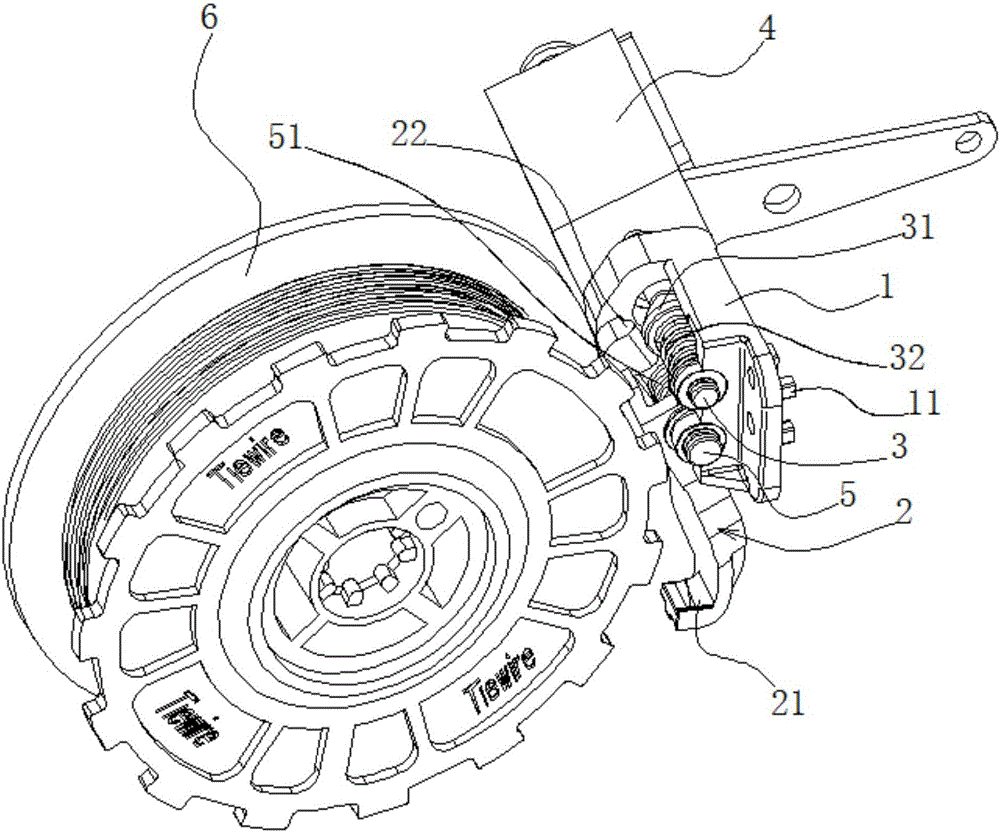

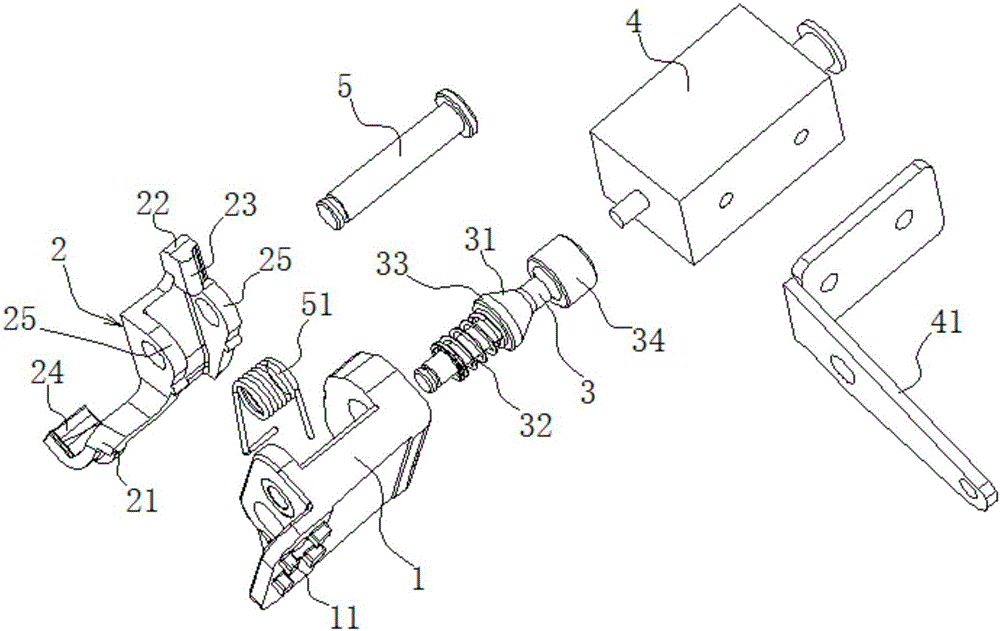

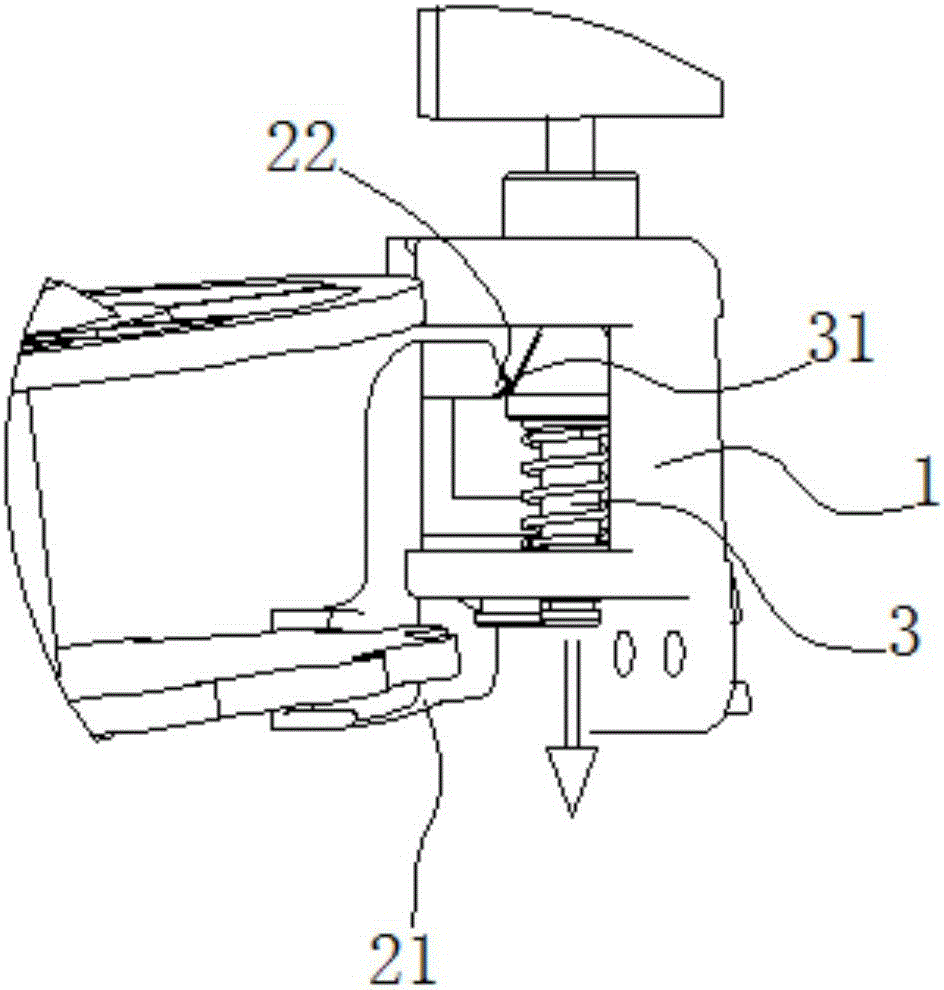

[0021] see Figure 1 to Figure 3 , a brake device for a fully automatic steel bar binding machine wire reel provided by the present invention includes a brake seat 1, a brake pad 2 installed on the brake pad 1, and a brake for driving the brake pad 2. shaft 3 and the power component 4 that drives the brake shaft 3, the brake pad 2 is hinged on the brake seat 1 through a hinge shaft 5, and the brake pad 2 is formed by the hinge shaft 5 The braking end 21 and the driving end 22, the braking end 21 is suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com