Method of cleaning diesel particulate filters

A technology for particulate filters, diesel engines, applied in cleaning methods and utensils, membrane filters, chemical instruments and methods, etc., and can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

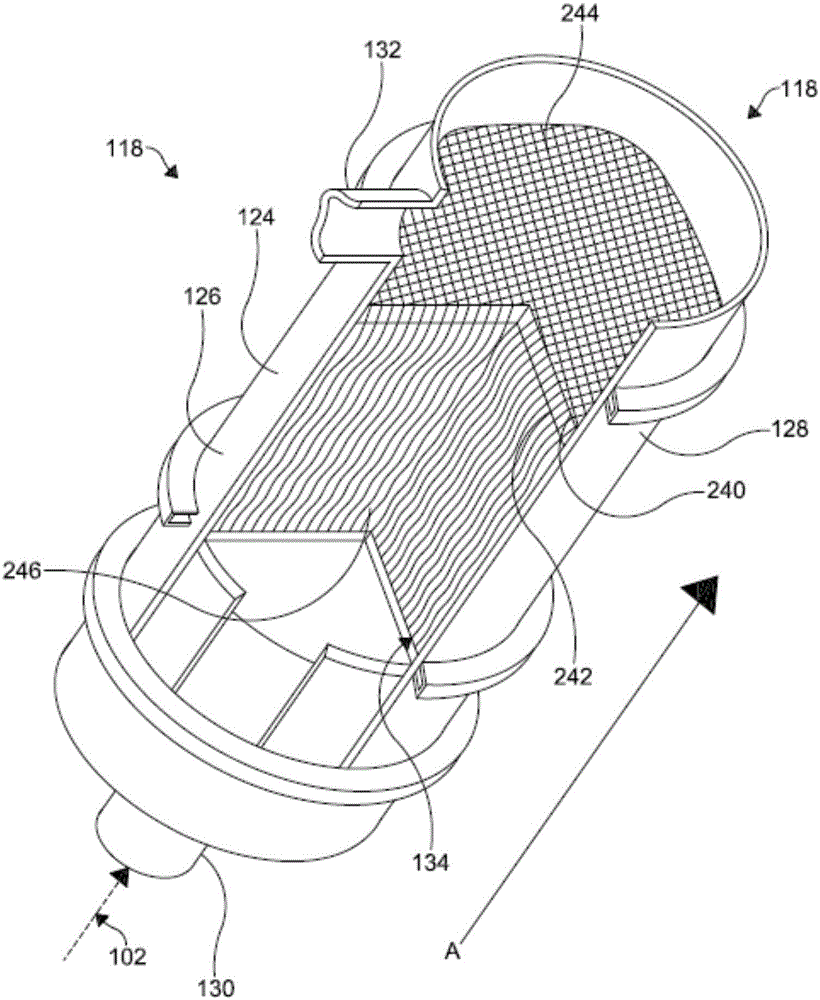

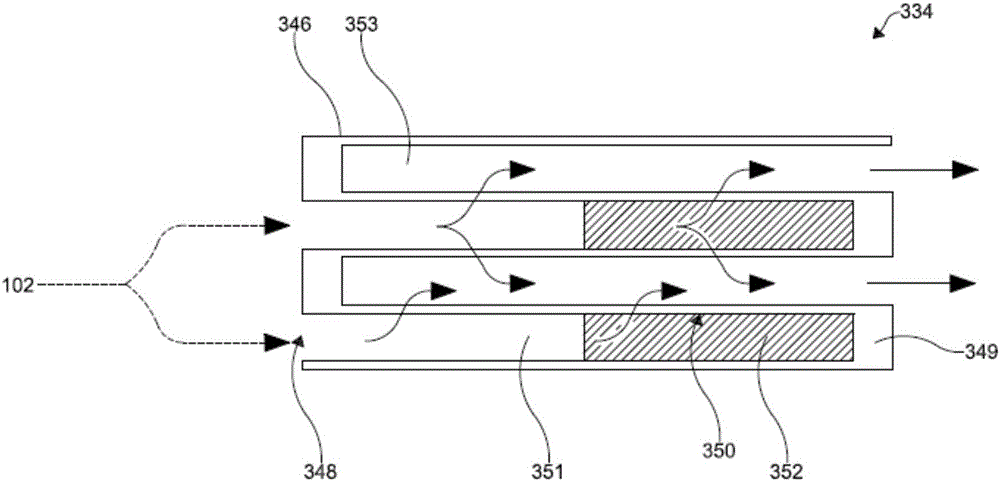

[0018] The present disclosure relates to a system and method for removing particulates accumulated in a DPF through the use of blocking agents. According to various aspects of the methods disclosed herein, blocking agents can be selectively applied to the filter media of the DPF. A DPF particle removal process with pneumatic air knives can be used to remove particles. In this way, the blocking agent can block the air flow of the air knife and thereby redirect and focus the air flow in the area of the DPF filter wall that is not blocked. After removal of the microparticles, the blocking agent can be removed.

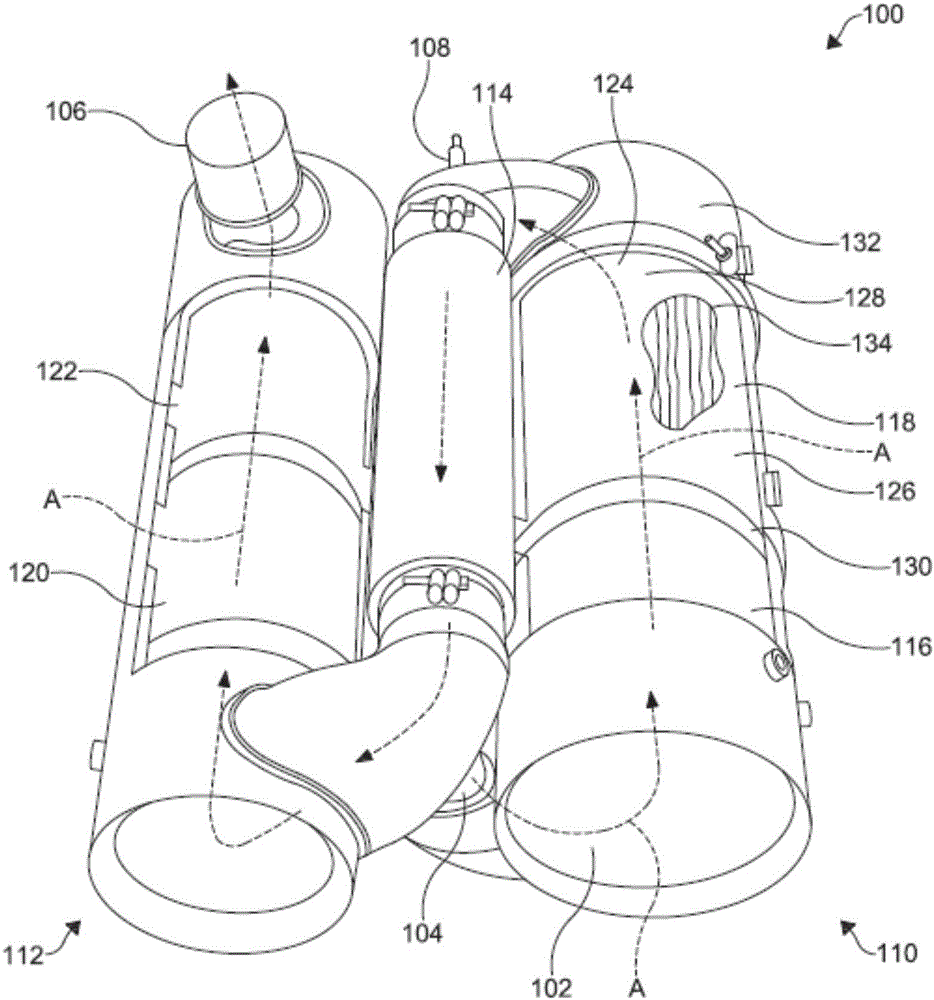

[0019] Such as figure 1 As shown in , an aftertreatment system 100 may be configured to limit or remove particulate matter in an engine exhaust stream 102 . The aftertreatment system 100 may include a system inlet 104 for an engine exhaust flow 102 from an internal combustion engine (not shown), a system outlet 106 , a reductant supply 108 , a first housing 110 , and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap