Diesel vehicle engine synchronous belt

A technology of timing belts and engines, applied in transmission belts, mechanical equipment, belts/chains/gears, etc., can solve the problem of single reinforcing skeleton of engine timing belts, and achieve the effects of enhanced strength, increased service life, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

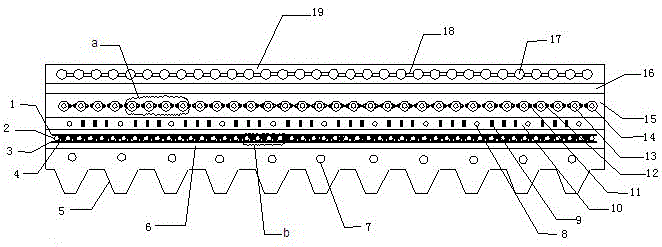

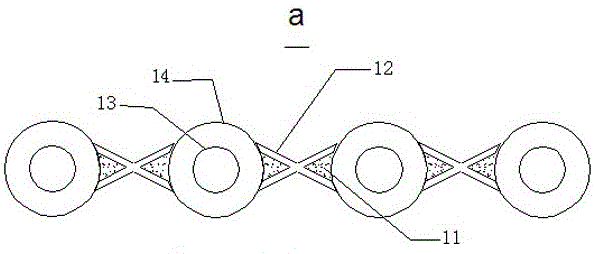

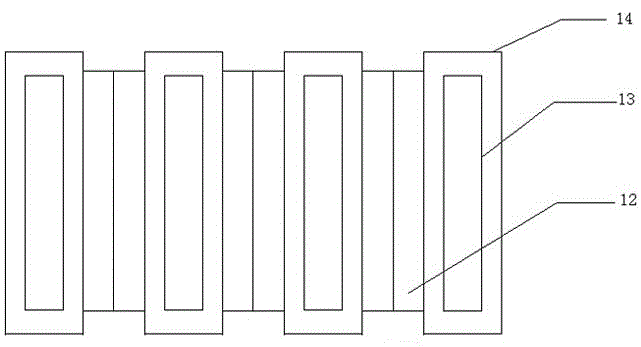

[0017] The invention relates to a synchronous belt for a diesel vehicle engine, comprising an endless belt, the endless belt comprising a second asbestos cloth 1, a first aramid fiber cord 2, a first asbestos cloth 3, a second adhesive glue 4, a tooth layer 5, a second asbestos cloth Four adhesive layers 6, the first heat dissipation hole 7, the second heat dissipation hole 8, polyester staple fiber 9, the third adhesive layer 10, the first adhesive glue 11, reinforcing rib 12, steel wire core wire 13, asbestos cloth cover 14, The second adhesive layer 15, the imitation inner cowhide elastic layer 16, the second aramid fiber cord 17, the third aramid fiber cord 18 and the first adhesive layer 19, the first adhesive layer 19 is embedded along the width direction of the synchronous belt There is a second aramid fiber cord 17, a third aramid fiber cord 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com