Vibration-reducing support device for pipeline system

A vibration-absorbing support and piping system technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of single vibration absorption frequency, inability to realize the vibration of the piping system, etc., and achieve the effect of convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

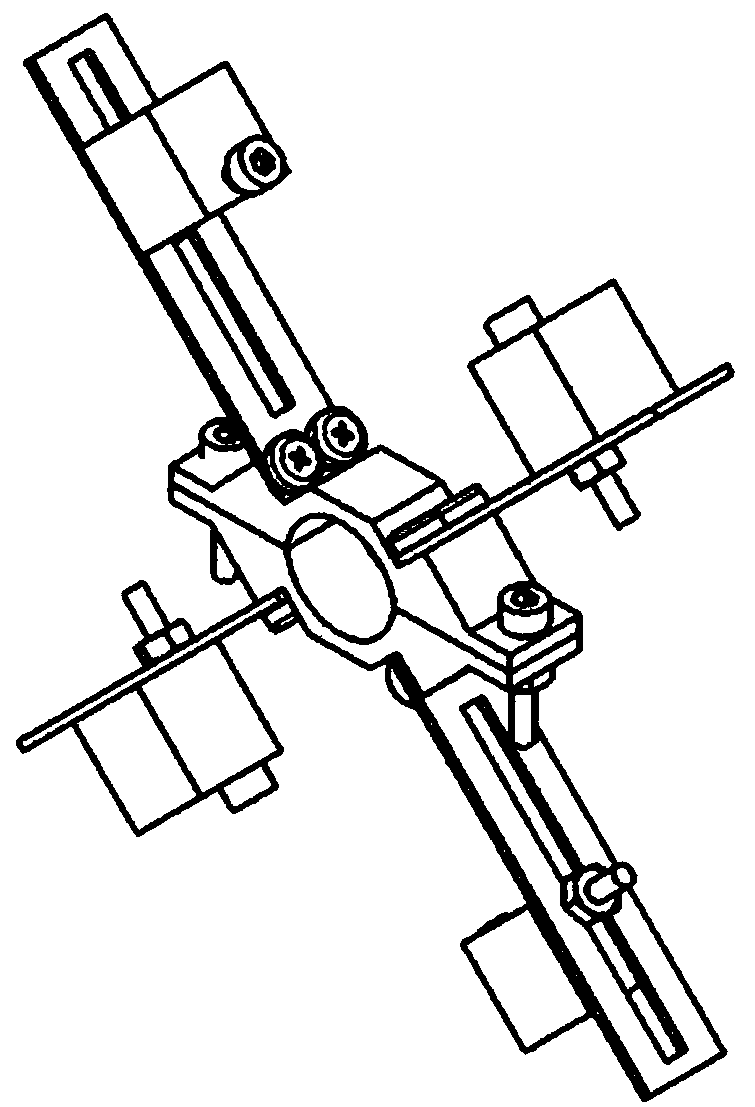

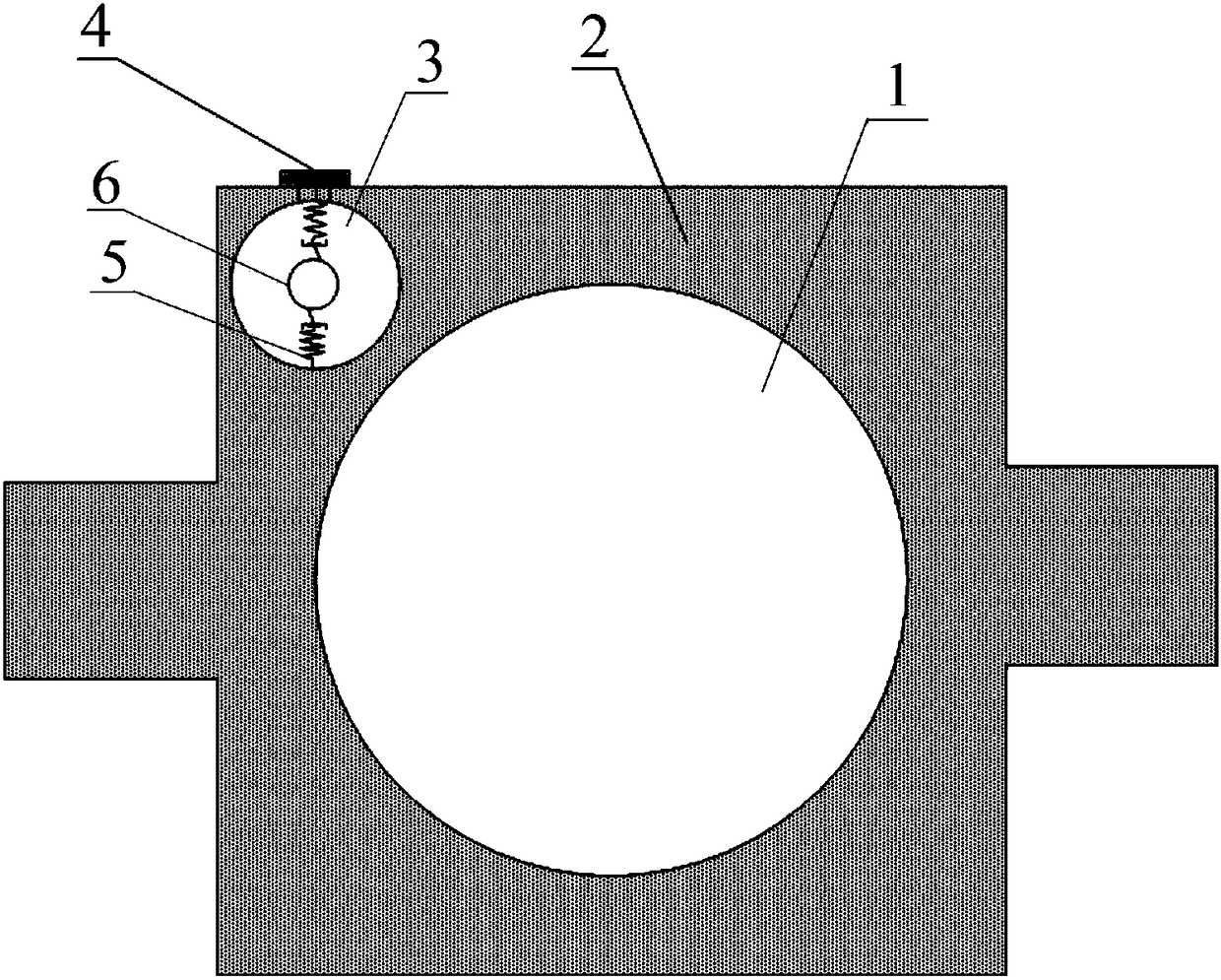

[0049] Such as figure 2 As shown, a pipeline system vibration damping support device includes a support 2 made of damping material, the support 2 is provided with a channel 1 for supporting and fixing the pipeline; a vibration absorber 3, the vibration absorber 3 includes a support The mass block 6 and two springs 5 in the part 2; at the same time, a receiving chamber is provided in the support member 2, and the mass block 6 is accommodated in the receiving chamber, and the two springs 5 are connected to the mass block 6 oppositely so that the The mass block 6 is elastically held in the housing cavity, and the housing cavity provides a vibration space for the mass mass 6 to vibrate in any direction; when the mass block 6 is at rest, two springs 5 are collinearly arranged, and two One end of the spring 5 is connected to the mass block 6, and the other end is connected to the inner wall of the storage cavity. Two springs 5 form a spring group. Tuner 4 of spring rate; s...

Embodiment 2

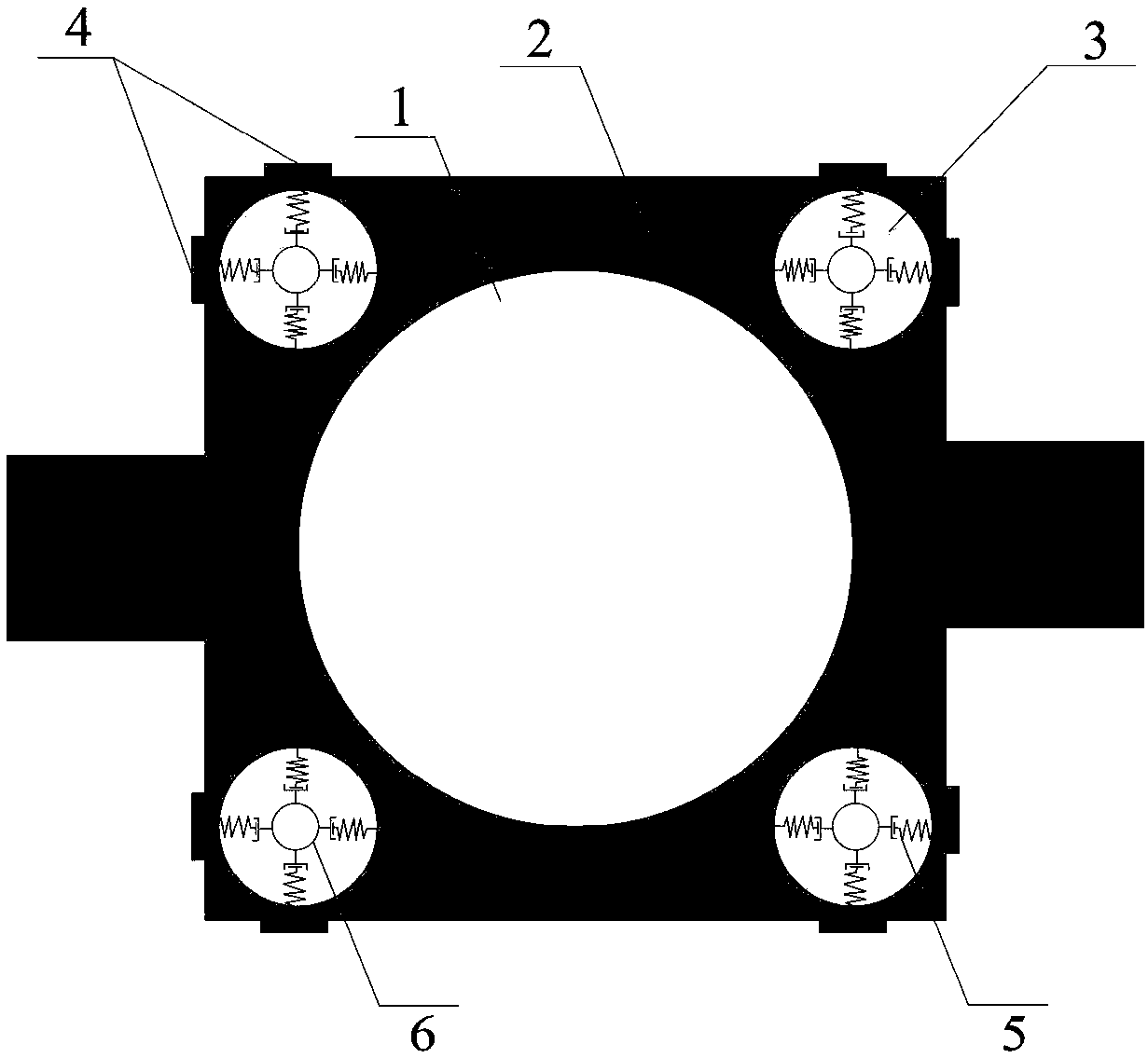

[0051] Such as image 3 , Figure 5 As shown, the pipeline system vibration damping support device in this embodiment is basically the same as that in Embodiment 1, the difference is that the number of vibration absorbers 3 is four, and the four vibration absorbers are evenly distributed around the channel. The shock absorber 3 is provided with six springs 5, and a three-dimensional coordinate system is established with the center of gravity of the mass block 6 as the origin, and the six springs 5 are respectively located in the X, Y, Z, -X, -Y, and -Z directions of the three-dimensional coordinate system in space. In the corresponding position, one end of the six springs 5 is connected to the mass block 6, and the other end is connected to the inner wall of the storage cavity. The six springs 5 form three sets of springs on the X, Y, and Z axes of the three-dimensional coordinate system, and each set of springs includes Two springs 5 respectively located in the posit...

Embodiment 3

[0053] Such as Figure 4 As shown, the pipeline system vibration damping support device in this embodiment is basically the same as that in Embodiment 2, the difference is that: the support 2 includes an upper support located above the channel 1 and a lower support located below the channel 1; the lower support There is also a support frame 7 with bolt holes 8 connected to it, and the support frame 7 is connected to the base by bolts; the stiffness of all the springs in the vibration-damping support devices of all piping systems are different; the support 2 is made of metal-based damping composite material .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com