Air distribution device for biomass fluidized-bed boiler

A technology of fluidized bed boiler and air distribution device, which is applied in the direction of fluidized bed combustion equipment, burning fuel in a molten state, lighting and heating equipment, etc., and can solve problems such as reducing work efficiency, reducing boiler load, and increasing maintenance costs. Achieve the effects of reducing maintenance costs, improving slag discharge capacity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

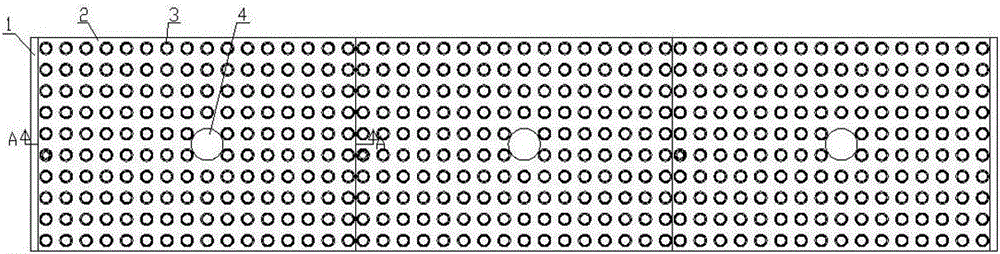

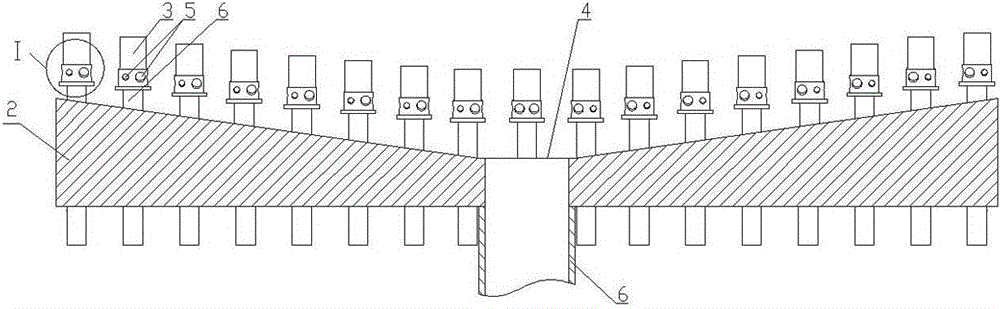

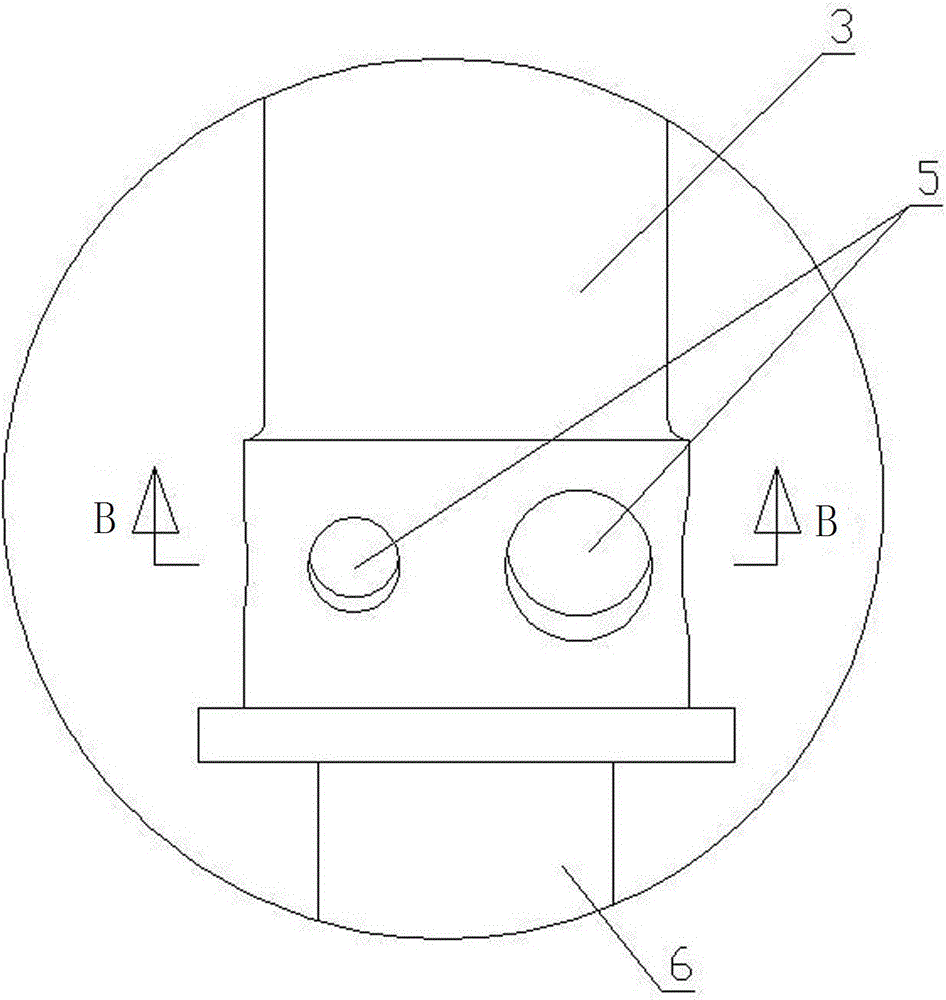

[0015] Such as Figure 1~Figure 4 As shown, the air distribution device for a biomass fluidized bed boiler of the present invention includes a bracket 1 on which a horizontally arranged air distribution plate 2 is arranged. There are no less than three air distribution boards 2, which are arranged side by side on the same horizontal straight line, and two adjacent air distribution boards 2 are connected together. The air distribution plate 2 is evenly processed with through holes, and the air distribution pipes 6 are fixed in the through holes. The wind cap 3 is evenly distributed with distribution air holes 5 around the wind cap 3 . The air distribution plate 2 is provided with a slag outlet 4 , and a slag outlet pipe 6 is connected to the lower end of the slag outlet 4 . The upper surface of the air distribution plate 2 is gradually lowered from the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com