Method for using isolated soybean protein to functionally modify single-walled carbon nanotube

A technology of single-walled carbon nanotubes and soybean protein isolate, which is applied in the direction of single-walled carbon nanotubes, carbon nanotubes, chemical instruments and methods, etc., can solve the problems affecting the loading capacity, achieve improved dispersibility, improve dispersibility, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

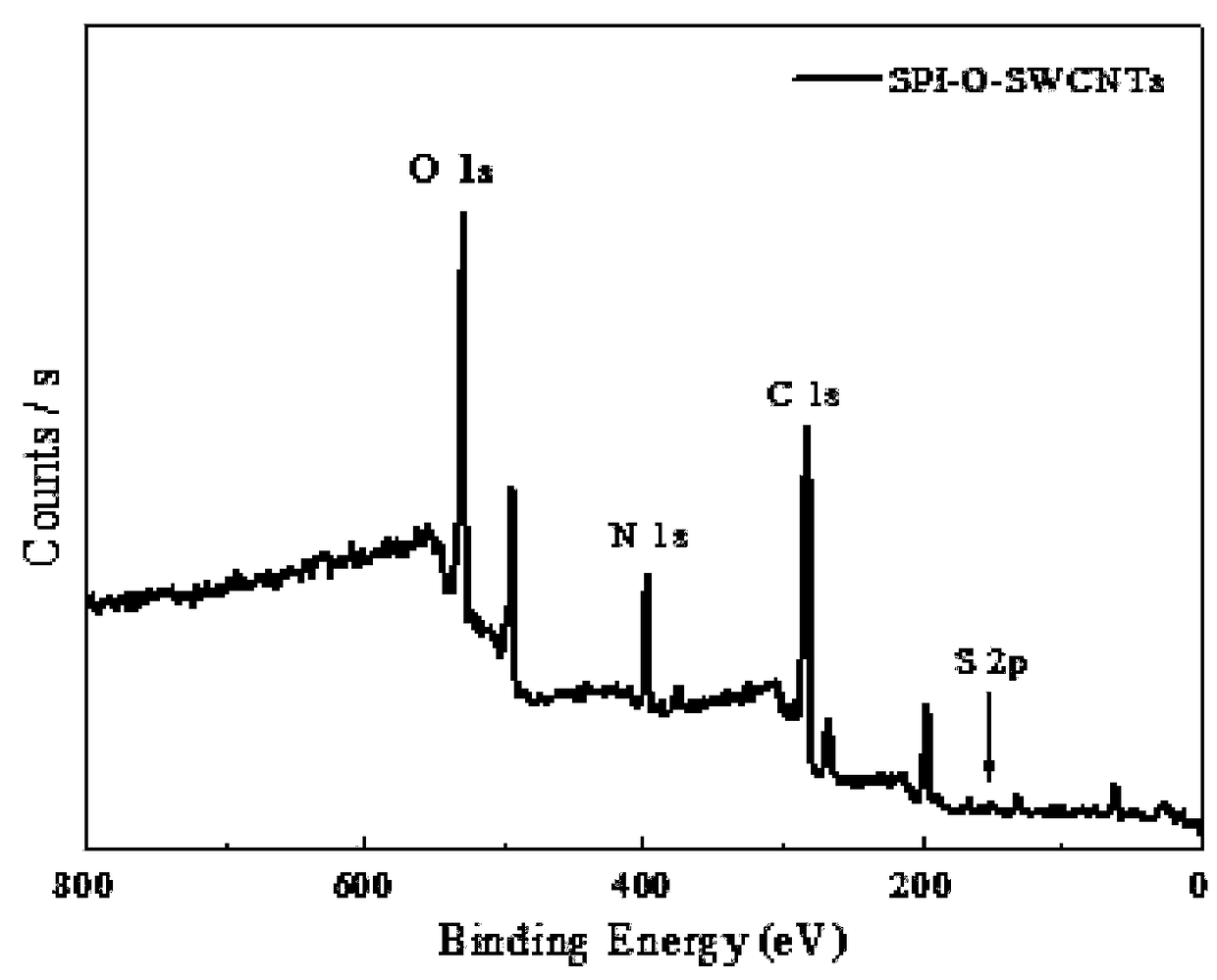

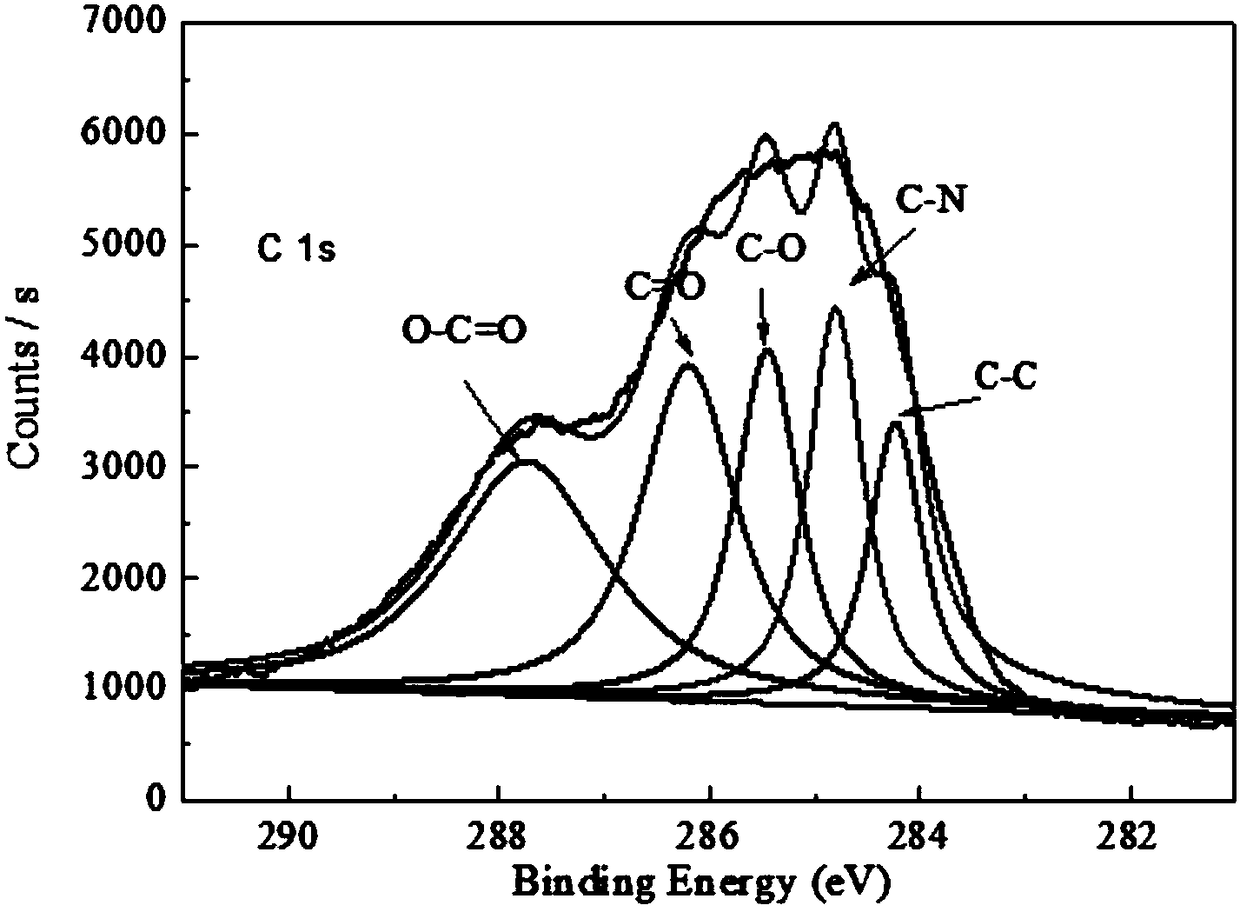

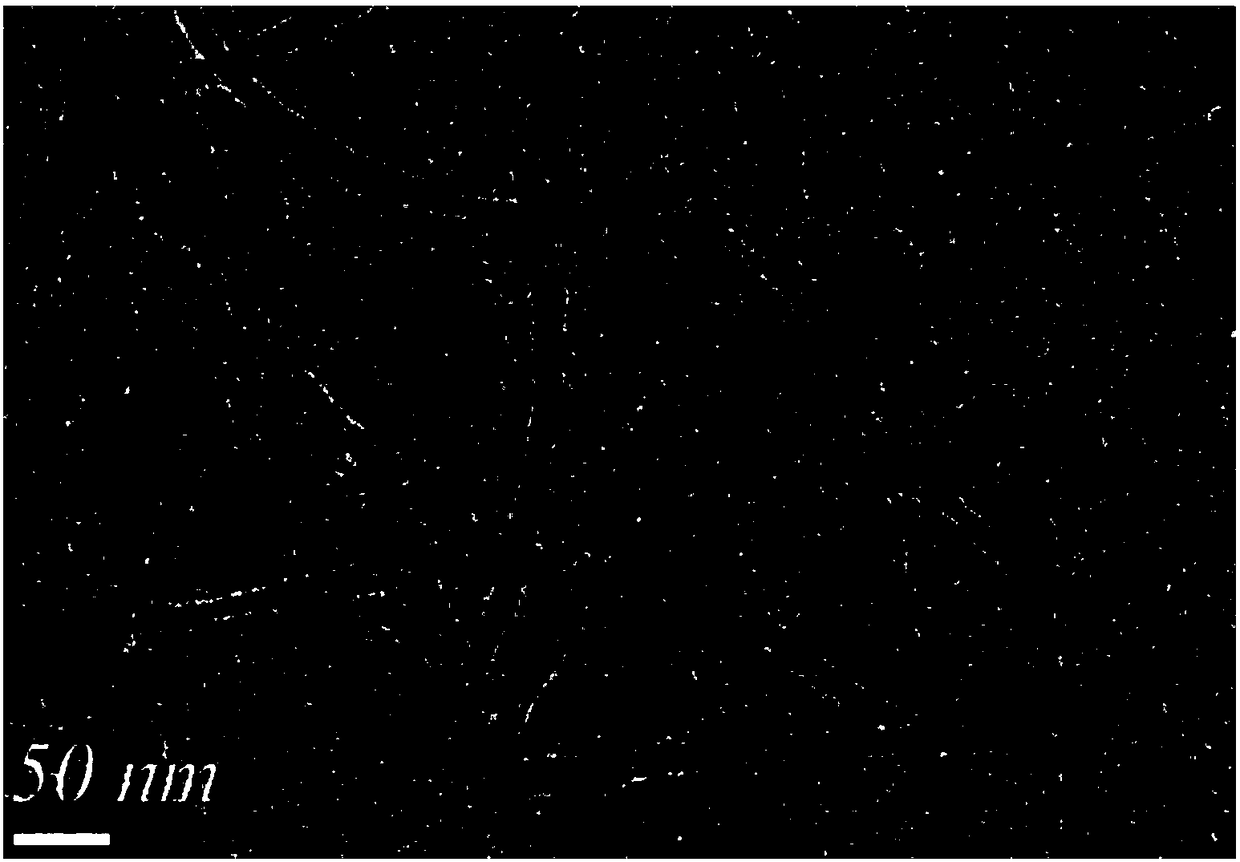

[0029] Mix 98%wt concentrated sulfuric acid solution with 69.8%wt concentrated nitric acid solution at a volume ratio of 3:1, and transfer 100mL to a three-necked flask. 50 mg of single-walled carbon nanotubes were added into the above-mentioned three-neck flask, condensed and refluxed at 80° C., stirred for 6 hours, and cooled to room temperature. The acidified single-walled carbon nanotubes were suction-filtered and washed with ultrapure water until neutral. Add 1 mg of the above-mentioned acidified single-walled carbon nanotubes to 20 ml of ultrapure water, and sonicate the probe for 40 min in an ice-water bath. Add 40 mg of soybean protein isolate, and ultrasonicate the probe for 40 minutes in an ice-water bath with a power of 300 W for 3 seconds and an interval of 2 seconds. The mixed solution was centrifuged at 10000r / min for 30min, the supernatant was taken, and the supernatant was placed in a freeze dryer to lyophilize.

[0030] The content of single-walled carbon na...

Embodiment 2

[0039]Mix 98%wt concentrated sulfuric acid solution with 69.8%wt concentrated nitric acid solution at a volume ratio of 3:1, and transfer 250mL to a three-necked flask. 100 mg of single-walled carbon nanotubes were added into the above-mentioned three-necked flask, condensed and refluxed at 80° C. and stirred for 6 hours, and cooled to room temperature. The acidified single-walled carbon nanotubes were suction-filtered and washed with ultrapure water until neutral. Add 1 mg of the above-mentioned acidified single-walled carbon nanotubes to 20 ml of ultrapure water, and sonicate the probe for 40 min in an ice-water bath. Add 30 mg of soybean protein isolate, and ultrasonicate the probe for 40 minutes in an ice-water bath, with a power of 400 W, ultrasonic for 3 seconds, with an interval of 2 seconds. The mixed solution was centrifuged at 10000r / min for 30min, the supernatant was taken, and the supernatant was placed in a freeze dryer to lyophilize.

[0040] High performance l...

Embodiment 3

[0043] Mix 98%wt concentrated sulfuric acid solution with 69.8%wt concentrated nitric acid solution at a volume ratio of 3:1, and transfer 150mL to a three-necked flask. 70 mg of single-walled carbon nanotubes were added into the three-necked flask, condensed and refluxed at 80° C., stirred for 6 hours, and cooled to room temperature. The acidified single-walled carbon nanotubes were suction-filtered and washed with ultrapure water until neutral. Add 1 mg of the above-mentioned acidified single-walled carbon nanotubes to 40 ml of ultrapure water, and sonicate the probe for 40 min in an ice-water bath. Add 50 mg of soybean protein isolate, and ultrasonicate the probe for 40 minutes in an ice-water bath with a power of 350 W for 3 seconds and an interval of 2 seconds. The mixed solution was centrifuged at 10000r / min for 30min, the supernatant was taken, and the supernatant was placed in a freeze dryer to lyophilize.

[0044] High performance liquid chromatography was used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com