Vertical rotary drying device for grain particles

A vertical rotation, grain particle technology, applied in the direction of grain drying, drying, dryer, etc., can solve the problems of low drying efficiency, uneven drying, damaged grain particles, etc., to improve the drying effect and efficiency, High heat transfer efficiency and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

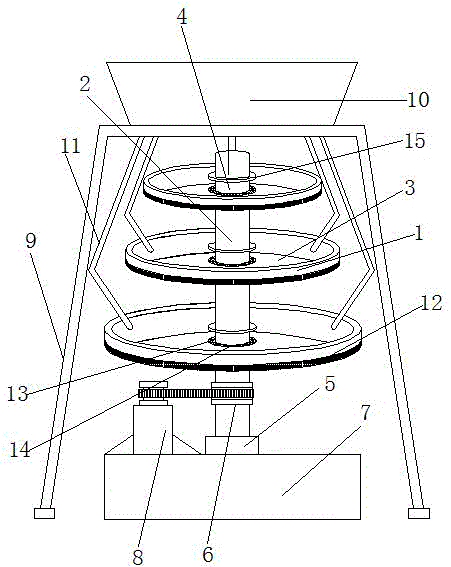

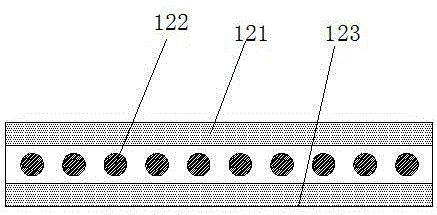

[0020] Refer to attached Figure 1-2 The shown vertical rotary drying device for grain grains includes several rotary trays 1, the inner diameters of which are sequentially increased from top to bottom, and the central positions of several rotary trays 1 are integrally arranged vertically The rotating shaft 4, and the vertical rotating shaft 4 is divided into several equal-height shaft joints 2 by several rotating trays 1, and a heating layer 12 is arranged at the bottom of each rotating tray 1, and the heating layer includes an upper aluminum plate layer 121 and the lower aluminum plate layer 123, and an electric heating element 122 is set between the upper aluminum plate layer 121 and the lower aluminum plate laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com