Rotary drum and drying machine comprising same

A rotary drum and dryer technology, applied in dryers, drying, sludge drying and other directions, can solve the problem of large heat loss and achieve the effects of less heat loss, stable structure, and stable and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

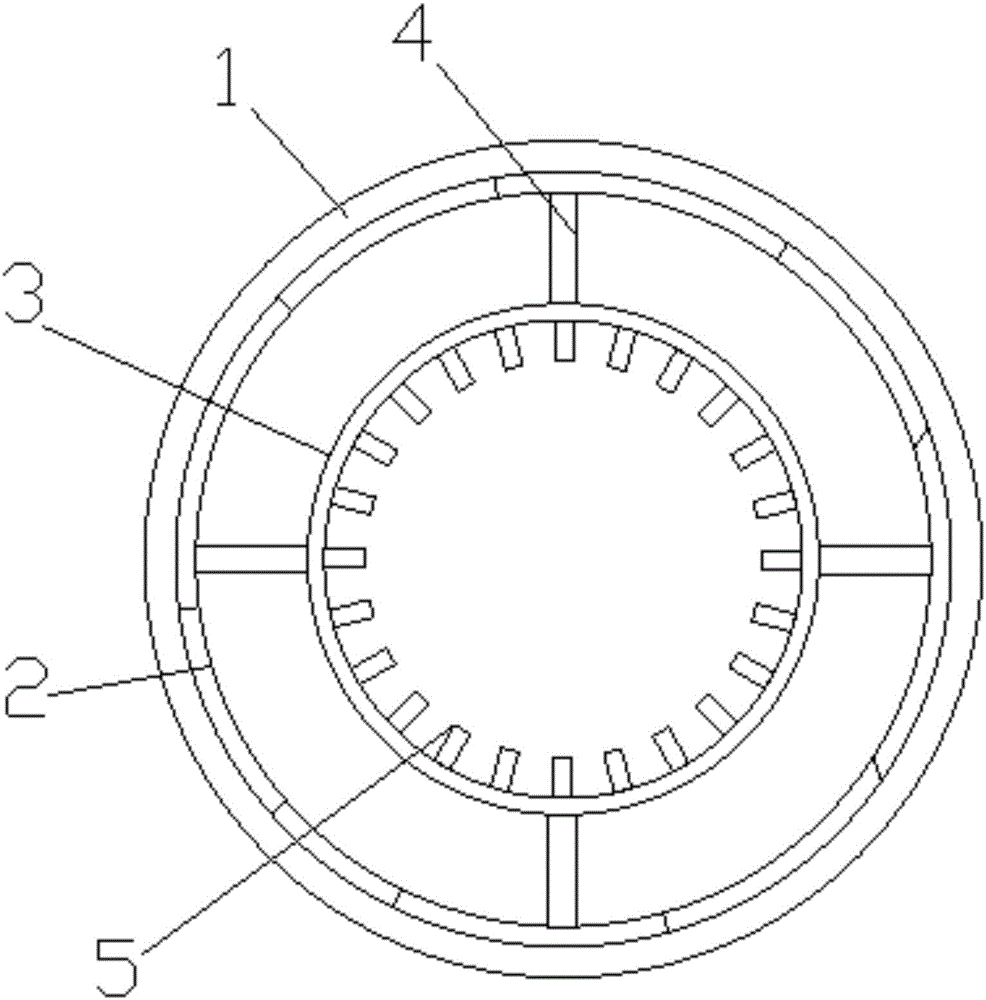

[0025] like figure 1 As shown, a rotary drum includes a rotary drum body 1 and a swirl plate 2, the swirl plate 2 is located on the inner surface of the rotary drum body 1 and is welded to the rotary drum body 1; the rotary drum body 1 A sieve 3 is arranged inside, and the sieve 3 is located at the same end as the feeding port of the rotary drum body 1. The rotary drum body 1 is fixedly connected with the sieve 3, and the sieve 3 operates synchronously with the rotary drum body 1. The sieve 3 is installed in the rotary cylinder body 1, compared with the traditional structure using a built-in mechanical dispersing device, since no cooling water is used, the loss of heat energy is small, and it will not be affected by the strength of the rotating shaft and the moment of inertia. Restrictions lead to the problem that the length of the breaking device and the length of the rotary drum cannot be designed too long.

[0026] The beneficial effects of the present invention are: the s...

Embodiment 2

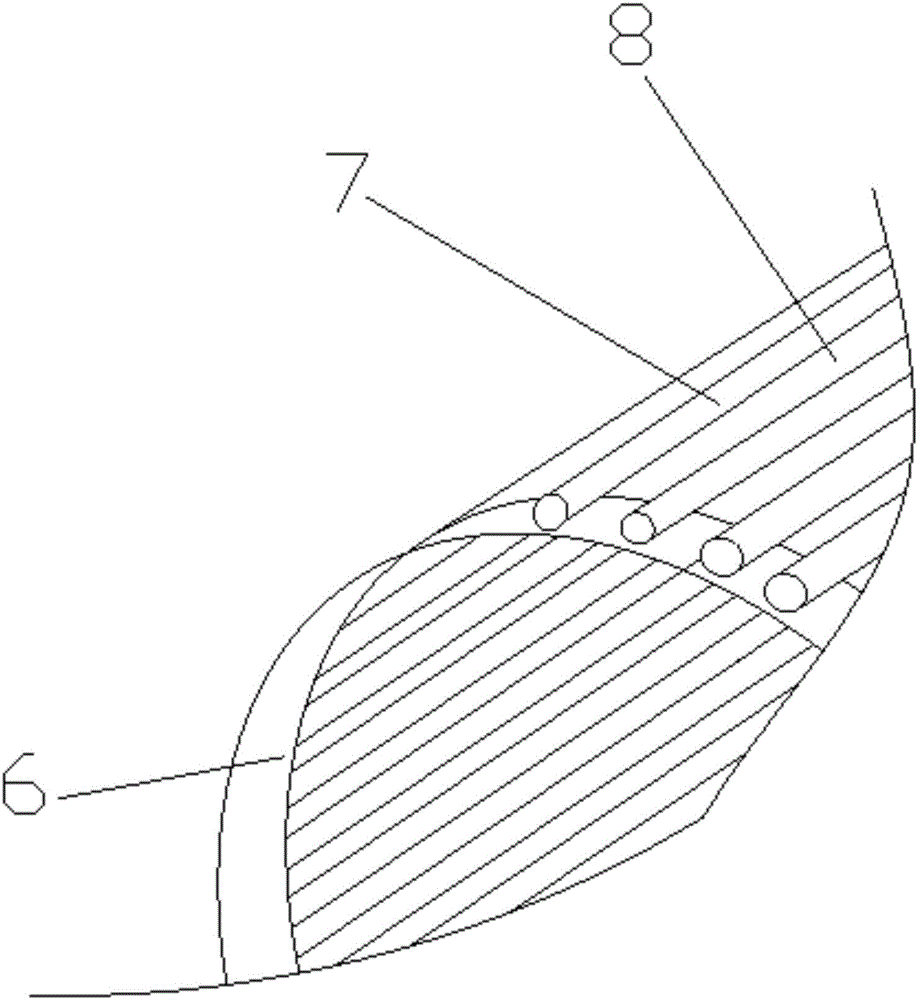

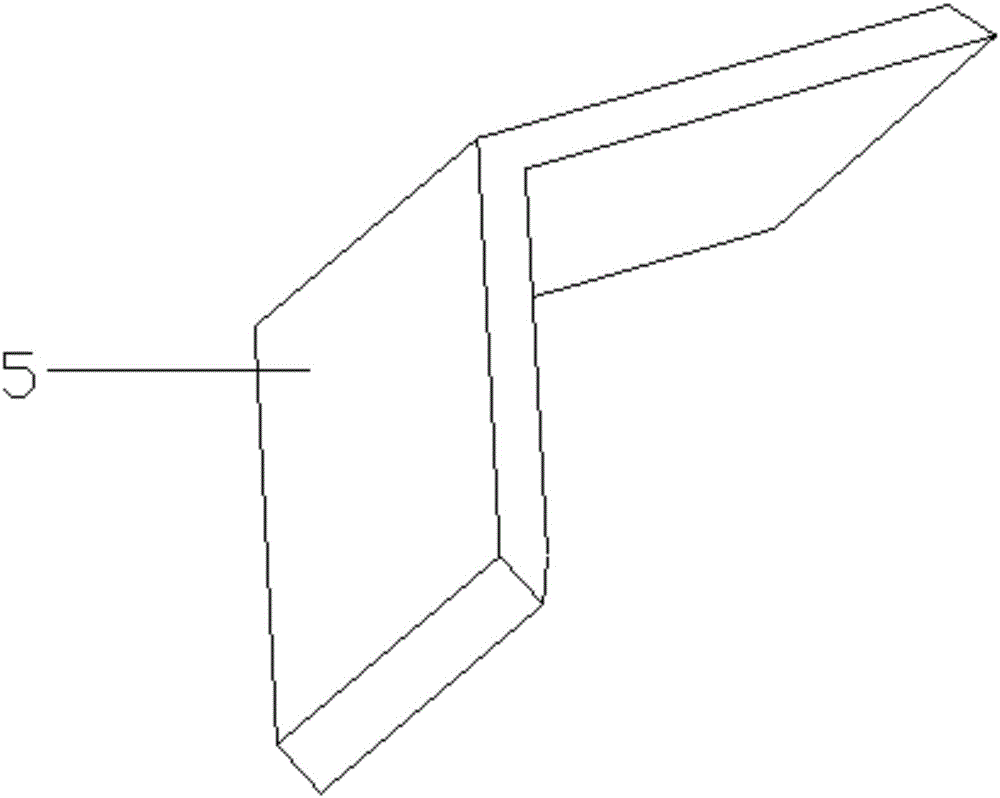

[0028] like Figure 1-3 As shown, a rotary drum includes a rotary drum body 1 and a swirl plate 2, the swirl plate 2 is located on the inner surface of the rotary drum body 1 and is welded to the rotary drum body 1; the rotary drum body 1 A sieve 3 is arranged inside, and the sieve 3 is located at the same end as the feeding port of the rotary cylinder body 1, and the rotary cylinder body 1 and the sieve 3 move in unison. A connecting frame 4 is arranged between the rotary drum body 1 and the sieve 3, and more than one connecting frame 4 is provided, and the connecting frame 4 is distributed in an annular array, and the rotary drum body 1 and the screen 3 are connected The connecting frame 4 is welded, and the rotary cylinder body 1 and the sieve 3 are connected through the connecting frame 4, so the structure is stable, and the connecting frame 4 is distributed in a circular array, which can effectively improve the stress stability of the sieve 3. The rotary cylinder body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com