Automatic routing inspection device for operation test bench

A technology of automatic inspection and operation test, applied in measuring devices, instruments, etc., can solve the problems of simple structure, incapable of complex operation test bench inspection, unable to achieve the effect of accurate inspection information, etc., and achieve fast and accurate data processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

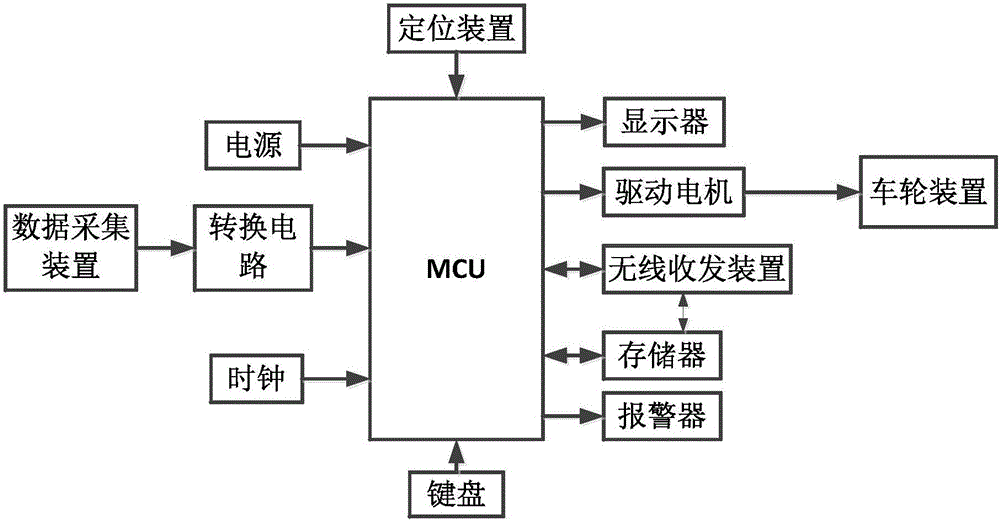

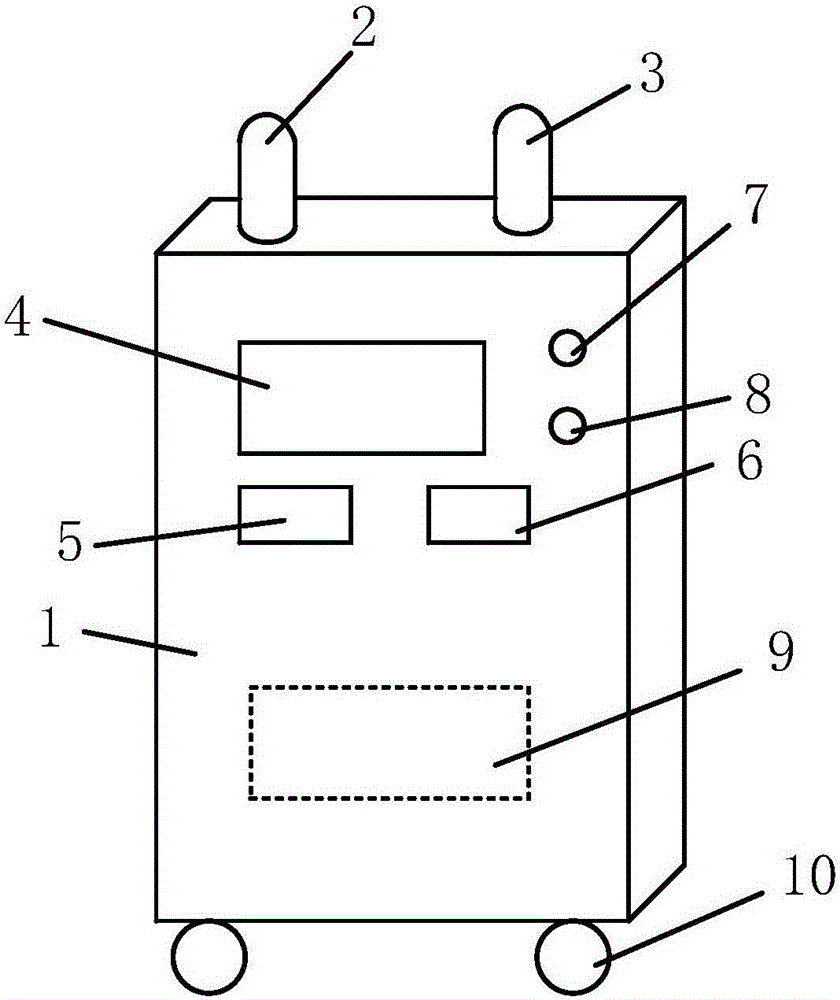

[0020] Such as figure 1 As shown, an internal detection system of an automatic inspection device for operating a test bench. The detection system includes a signal acquisition system, a control processing system, and a monitoring system. The acquisition system includes a sequentially connected data acquisition device and a conversion circuit. The data acquisition device includes sensors and Camera, the sensors include temperature sensor, humidity sensor and smoke sensor, to collect whether there is any abnormal state of the detected operation test bench, the camera includes high-definition camera and infrared camera, the surface image of the test bench can be captured by the high-definition camera, and the surface image of the test bench can be captured by the infrared camera The internal image of the camera can be checked thoroughly, and the hidden danger points of the test bench can be thoroughly checked. The conversion circuit is an A / D conversion circuit, which converts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com