Electronic multi-points modification method of membrane gas meter

A membrane gas meter and multi-point correction technology, which is applied in the field of metering instruments, can solve the problems of gas leakage and gas meters that cannot realize the multi-point correction function of ordinary base meters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

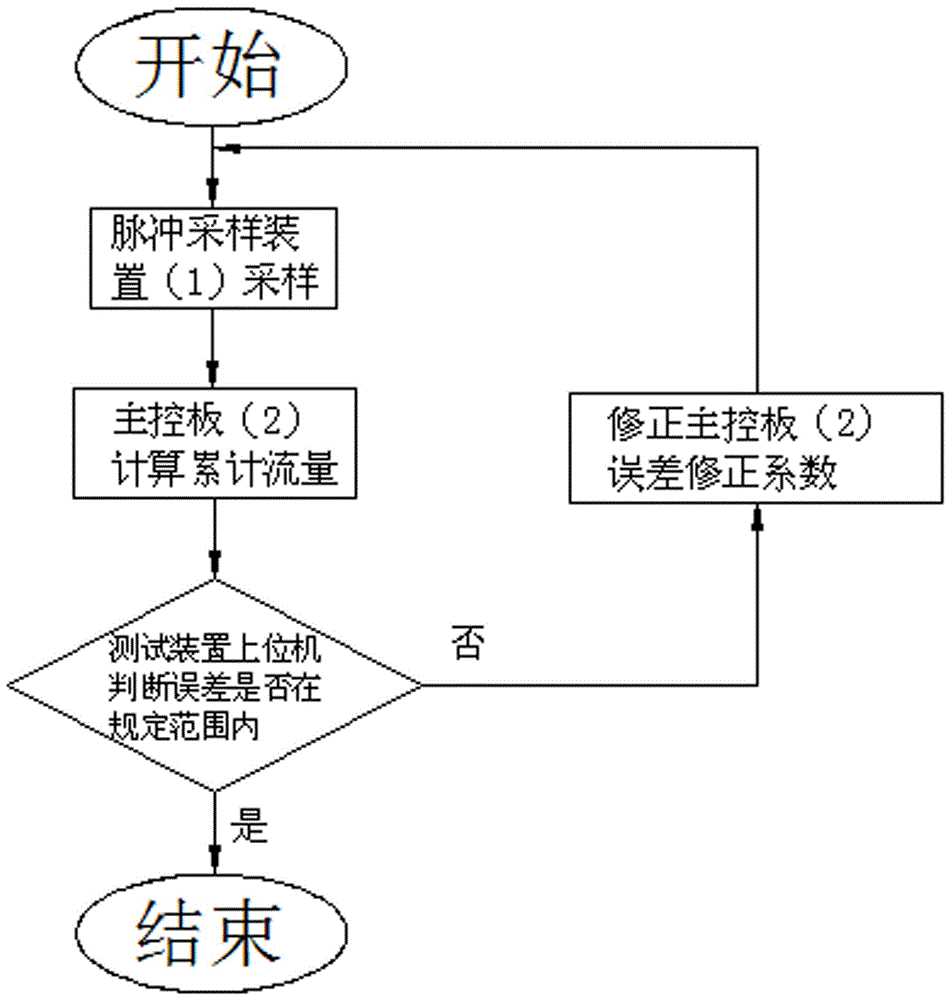

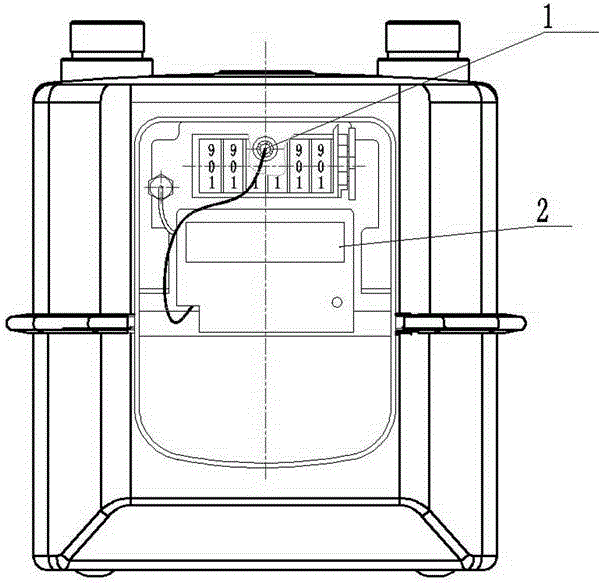

[0014] An electronic multi-point correction method for a membrane gas meter uses equipment including an electronic temperature correction membrane gas meter flow sampling device 1 and a main control board 2 . Electronic temperature correction membrane gas meter flow sampling device 1 is mainly composed of a sealing sleeve, a magnetic steel bracket, a pulse sampling sensor and a plurality of magnetic steel assemblies. The pulse sampling sensor is fixed on the fixed frame, and the fixed frame is fixed on the sealing sleeve. The pulse signal line of the pulse sampling sensor passes through the fixing frame. The cylindrical surface of the sealing sleeve is provided with a magnetic steel support, and the end of the sealing sleeve is provided with a flange. A plurality of magnetic steels are evenly arranged on the circumference of the magnetic steel support, which can achieve multiple pulse sampling in one rotary volume and realize high-resolution sampling. It is characterized by:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com