Bridge effective prestress force on-way distribution and attenuation testing device

A testing device and prestressing technology, which is applied in the direction of measuring device, measurement of the change force of the optical properties of the material when it is stressed, and measurement of force, can solve the problems of poor practical value and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

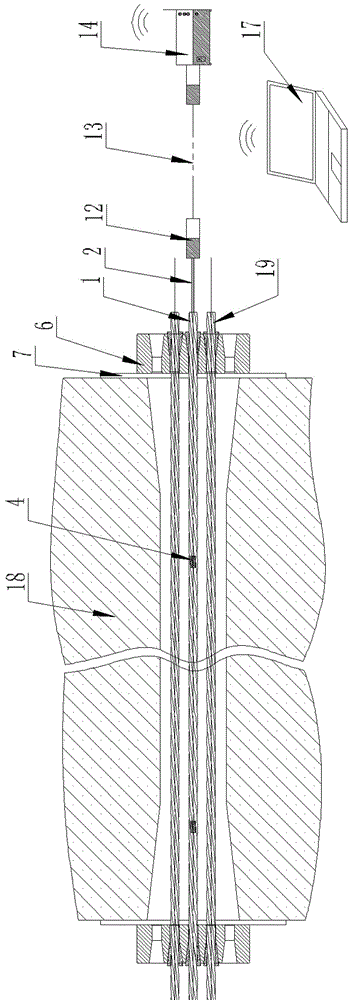

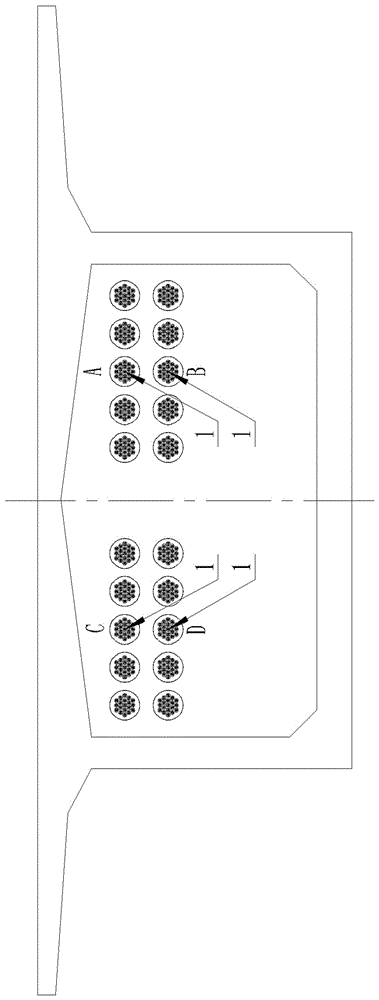

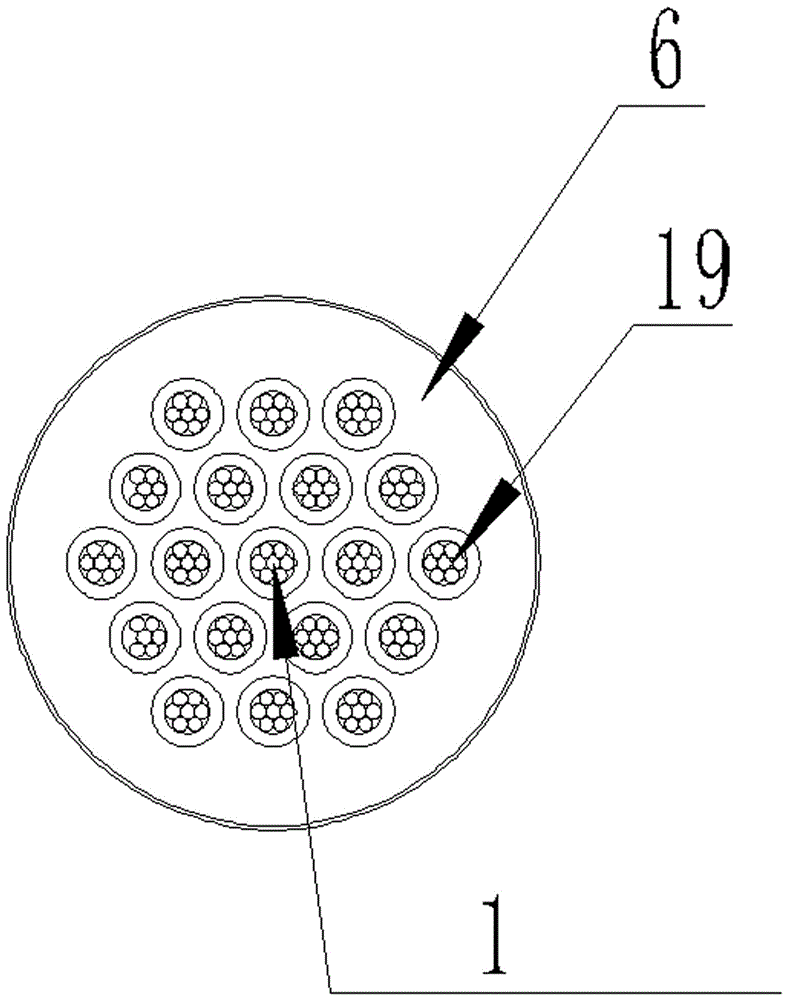

[0030] see Figure 1 to Figure 5, a bridge effective prestress along the distribution and its attenuation testing device, including a data collector 14, a monitoring computer 17 and an intelligent steel strand 1 arranged in the bridge, the two ends of the intelligent steel strand respectively extend out of the two ends of the bridge At the end, the intelligent steel strand is formed by twisting a central wire and peripheral wires wound around the central wire, the central wire is a carbon fiber wire 2, and an optical fiber 3 with a fiber grating sensor 4 is built in it. The fiber grating sensors in the intelligent steel strand are distributed along the axis of the intelligent steel strand according to monitoring requirements. The lead-out line of the optical fiber grating sensor in the described intelligent steel strand is connected to the data collector 14 by optical cable, and the described data collector 14 communicates with the monitoring computer 17, and the prestress of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com