Angular vibration platform

An angular vibration table and stage technology, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of limited size of the DUT, low displacement execution accuracy, and large load on the voice coil motor. , to achieve the effect of accurate rotation, not easy to fatigue and fracture, and small beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

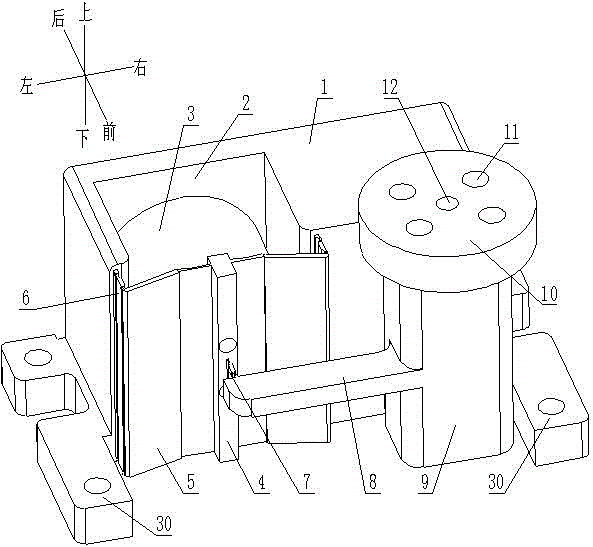

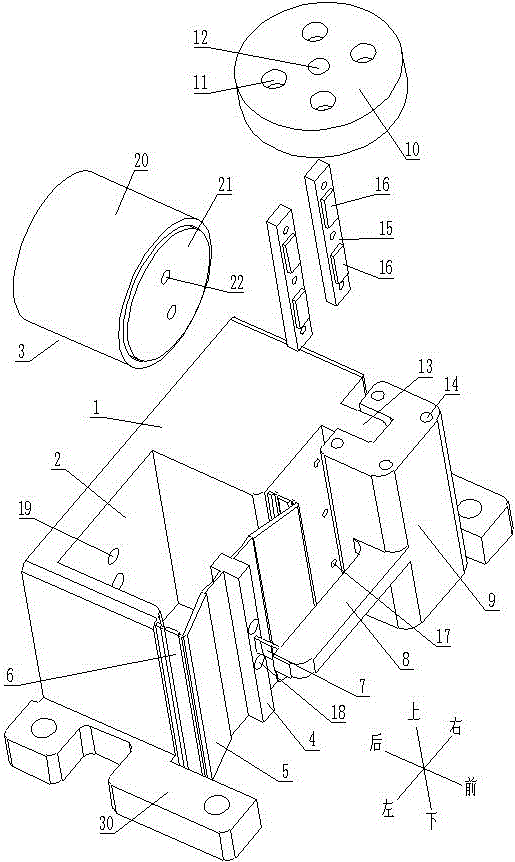

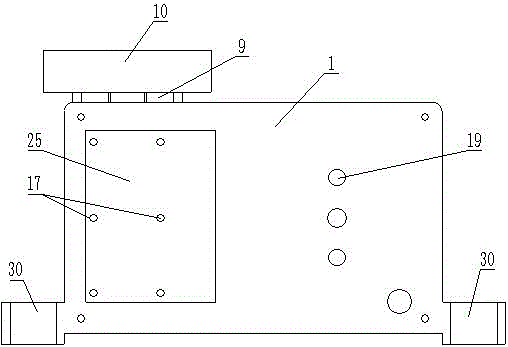

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as Figure 1-Figure 4 An angular vibrating table shown includes a base 1, a rotating support located on the front side of the base 1, and a stage 10 fixedly connected to the rotating support; between the right part of the rotating support and the base 1 Connected by a first flexible hinge 23, the rotation axis of the first flexible hinge 23 is set along the up and down direction; a connecting block 4 is arranged between the left part of the rotating support and the seat 1, and the left part of the connecting block 4 and the rotating supporting They are connected by a flexible transmission structure, and the connection block 4 and the base body 1 are connected by a guide mechanism; the voice coil actuator 3 is fixedly installed on the base body 1, and the output end of the voice coil actuator 3 is fixed to the connection block 4 connected, the voice coil actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com