Quantitative classification method for rock sample crushing degree based on grid density and crack density

A technology of grid density and crack density, applied in the field of rock mechanics test, can solve the problems of difficult rock mechanical properties, inability to quantitatively compare failure states, lack of quantitative index descriptions for crack development and fracture degree of rock samples, etc. Intuitive calculation results and accurate values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for quantitatively classifying rock sample fragmentation degree based on grid density and crack density, the method comprises the following steps:

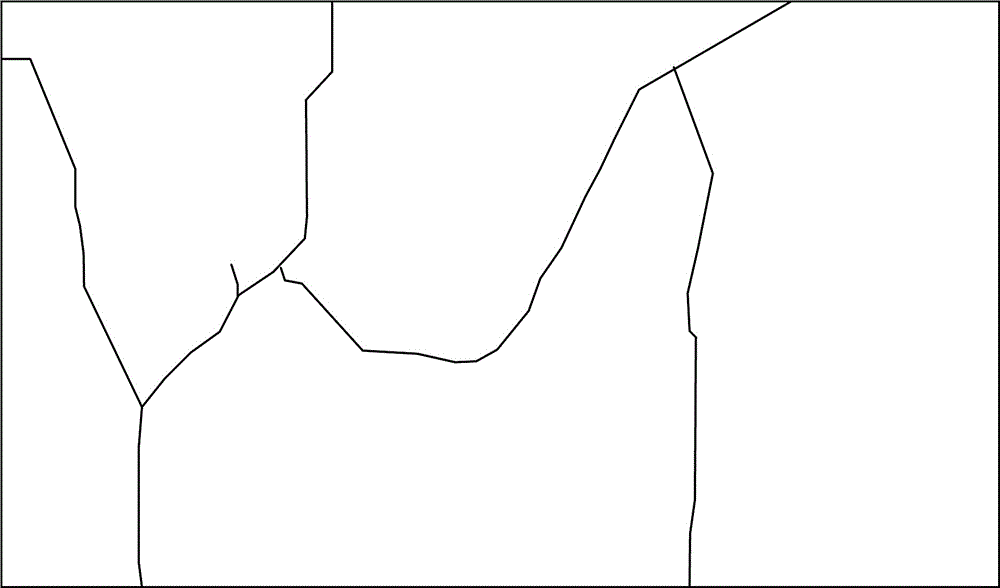

[0061] Step 1: Combining the literature data and a large number of sandstone, limestone, granite, sandstone, gneiss and other types of rocks completed in the laboratory in the early stage, the rock samples were destroyed under different loading and unloading stress paths, a total of 200 groups; 200 samples were obtained The crack development diagram of rock samples of the same size after failure, such as figure 1 shown;

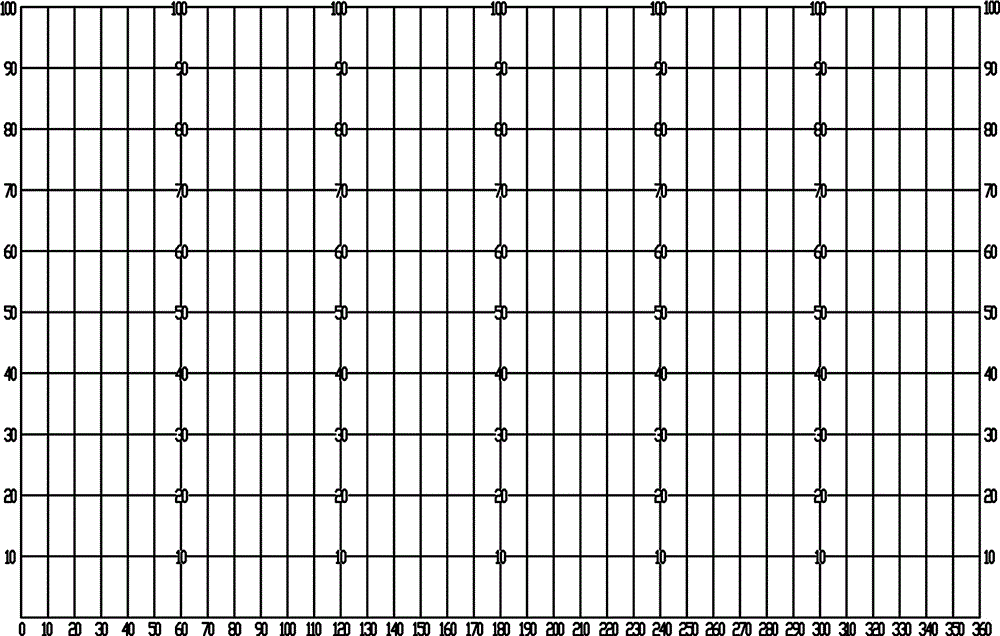

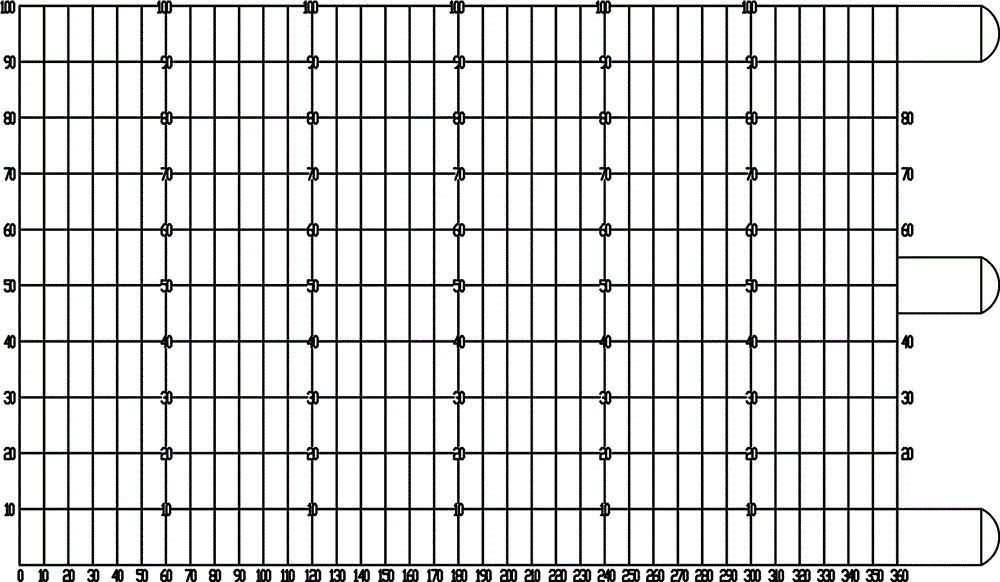

[0062] Step 2: Make a "360 grid" of each rock sample, and count the number of cracks in each crack development diagram obtained in step 1 through the "360 grid". Statistics are shown in Table 1:

[0063] Table 1 Statistical table of the number of cracks in rock samples

[0064]

[0065] Draw the relationship diagram between the number of cracks and the number of corresponding rock samples, s...

Embodiment 2

[0117] In order to verify the applicability and rationality of the classification method proposed by the present invention, a typical damaged rock sample is selected, and the rock sample fragmentation degree is calculated and evaluated according to the above method;

[0118] Depend on Figure 9 It can be seen that: 360 grid density Γ W is 0.08 (0J It is 0.2 (0<0.2<0.5), the category of rock sample fragmentation degree: relatively complete.

[0119] Depend on Figure 10 It can be seen that: 360 grid density Γ W 0.19 (0.1J It is 0.55 (0.5<0.55<0.8), and the category of rock sample fragmentation degree: relatively fragmented.

[0120] Depend on Figure 11 It can be seen that: 360 grid density Γ W is 0.42 (0.3J 0.95 (0.8<0.95<1.0), rock sample fragmentation category: fragmentation.

[0121] Depend on Figure 12 It can be seen that: 360 grid density Γ W 0.51 (0.5J It is 1.2 (1.2>1), and the rock sample fragmentation category: very fragmented.

[0122] Depend on Figure 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com