Early failure removal testing method for carrying industrial robot

An industrial robot, early failure technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of long time and high economic cost for early troubleshooting of robots, and achieve the effect of optimizing the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0201] The present invention is described in detail below in conjunction with accompanying drawing:

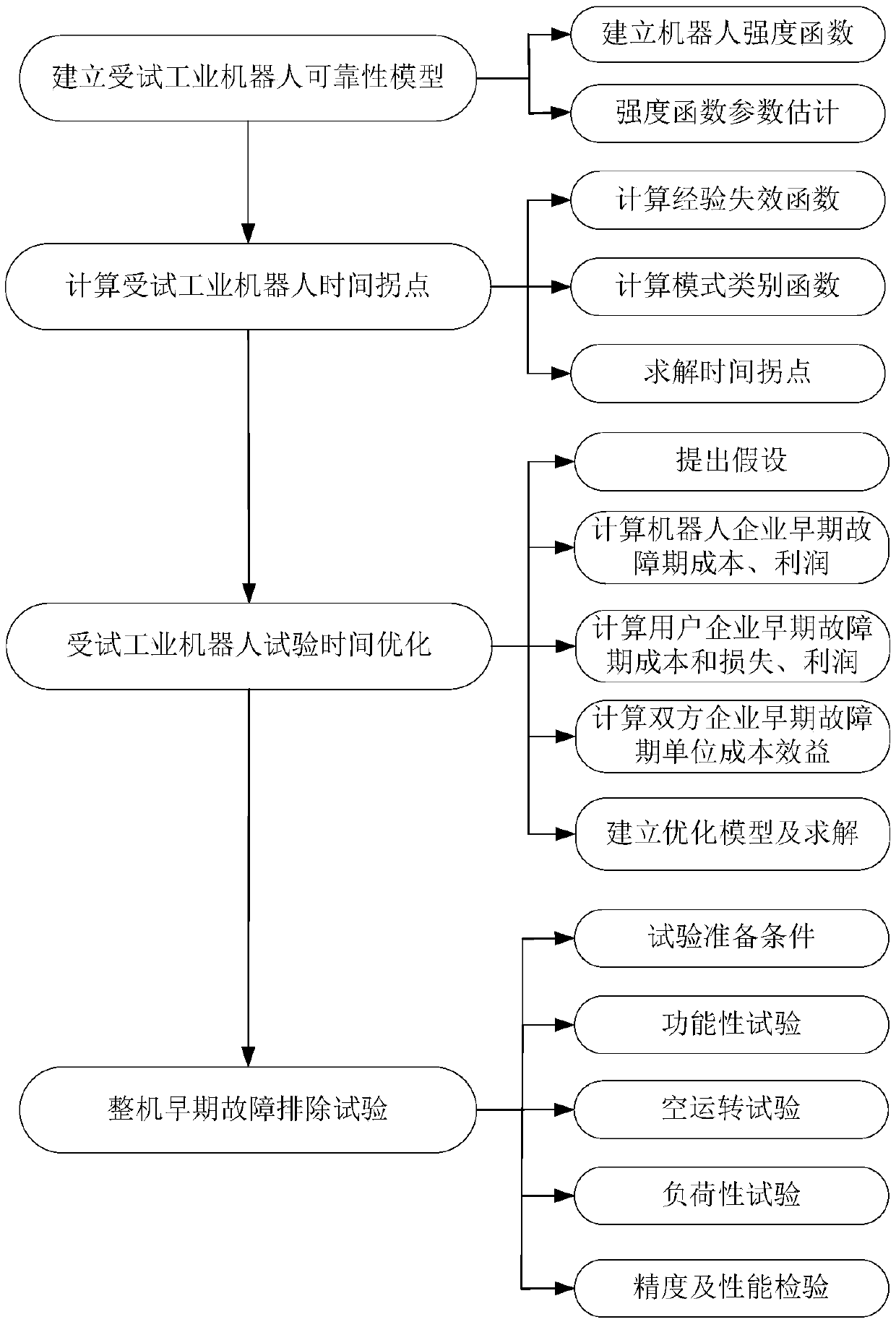

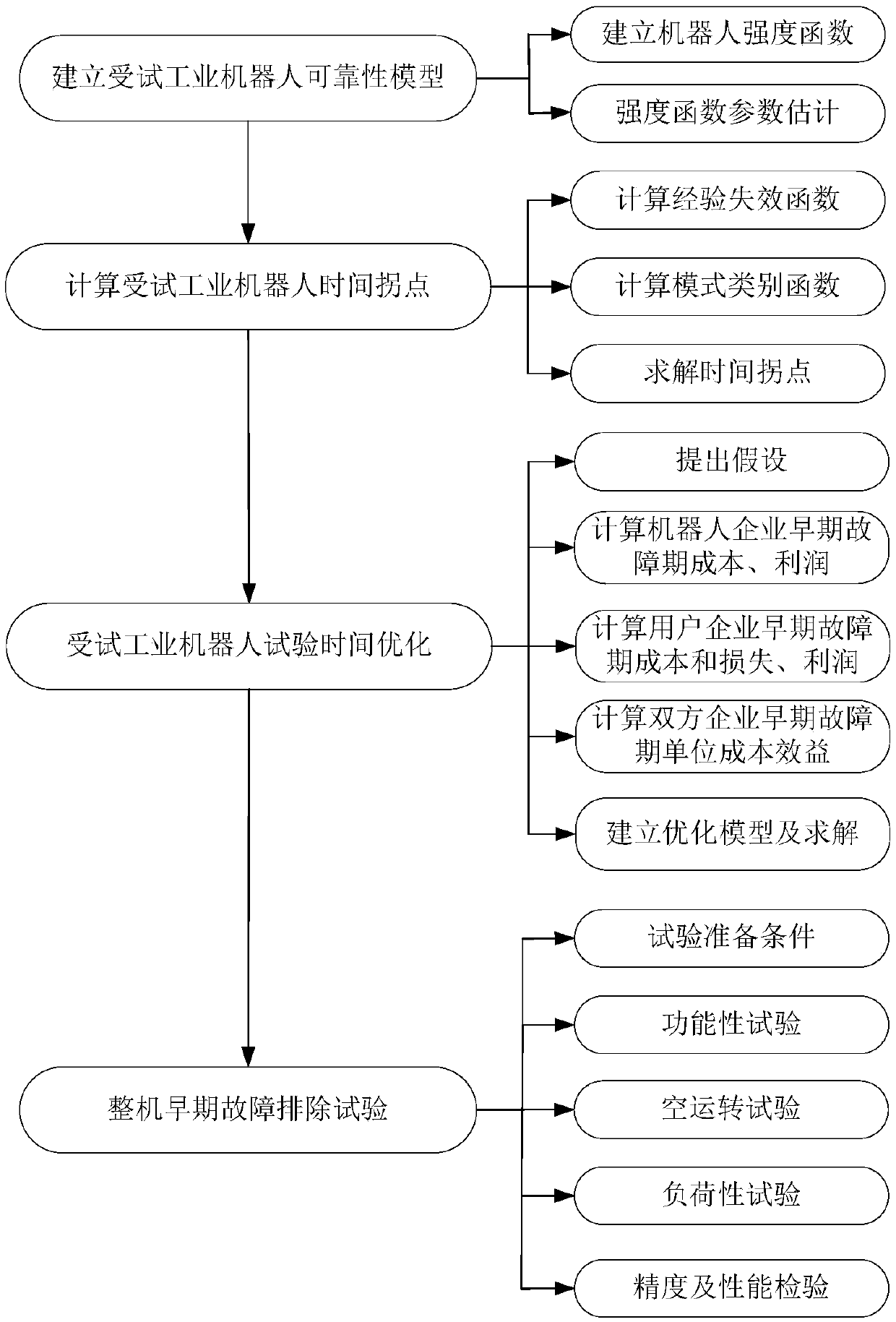

[0202] refer to figure 1 , a kind of handling class industrial robot early-stage troubleshooting test method of the present invention includes establishing the reliability model of the tested robot, calculating the time inflection point of the tested robot from the early failure period to the occasional failure period, and obtaining the time inflection point Based on the optimization of the test time of the tested robot and the early troubleshooting test of the whole machine of the tested robot. Among them, the test time of the tested robot is optimized with the maximum unit profit as the optimization goal. A test robot is a robot that is about to undergo an early troubleshooting trial.

[0203] The steps of an early troubleshooting test method for a handling industrial robot described in the present invention are as follows:

[0204] 1. Establish the reliability model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com