The method of generating hollow model based on solid model of finite element mesh

A solid model and finite element technology, which is applied in the field of additive manufacturing, can solve problems such as the inability to generate space hollow models, and achieve the effect of high feasibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

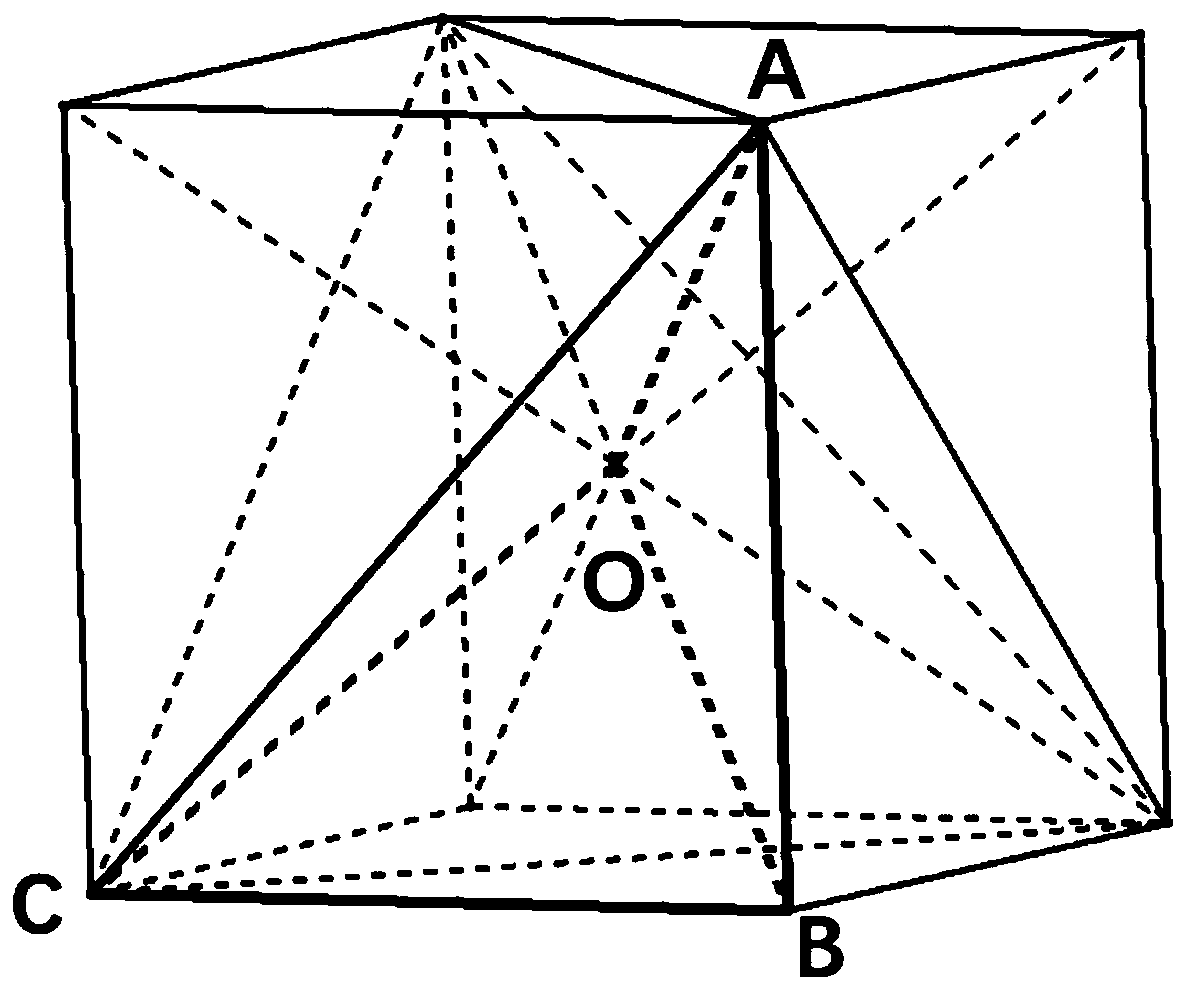

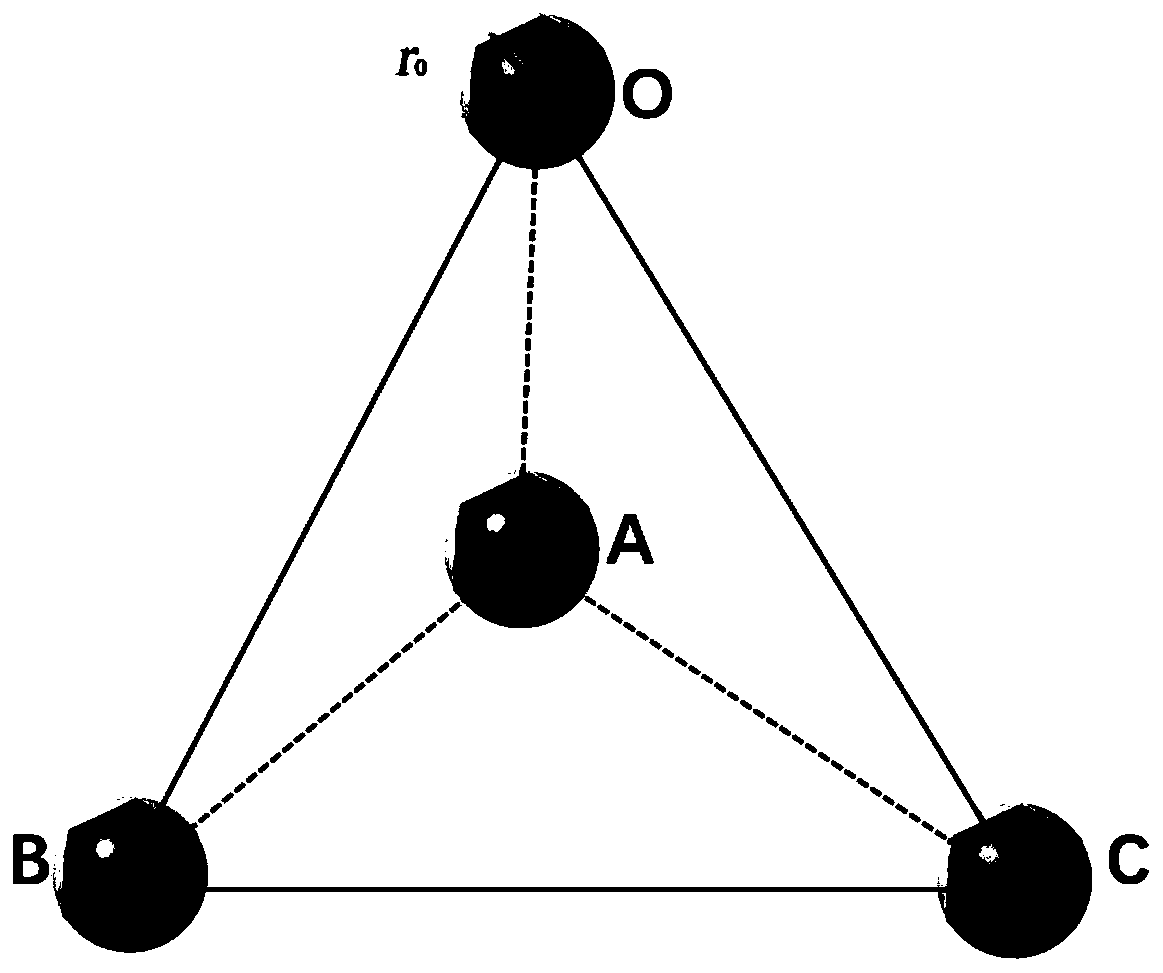

[0011] The method for generating a hollow model based on a solid model of a finite element grid according to the present invention will be described in detail below with reference to the accompanying drawings.

[0012] refer to Figure 1 to Figure 5 , the method for generating a hollowed-out model based on a solid model of a finite element grid of the present invention comprises the steps of: S1, establishing a solid model; S2, dividing the solid model into finite element volume units to obtain a finite element grid; S3, using a finite element network Each node of the lattice generates a spherical surface for the center of the sphere; S4, carry out triangular patch meshing on each spherical surface; S5, for each finite element volume unit, for each spherical surface in step S4, mark the nodes to which each spherical surface belongs and the spherical surface The intersection of the node line formed between the nodes of the adjacent spheres on the two spheres, determine the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com