Voltage-regulating winding end part insulating structure for controlling creepage for transformer

A voltage regulating winding and end insulation technology, applied in transformer/inductor components, transformer/inductor coil/winding/connection, circuits, etc., can solve creepage breakdown, high withstand voltage, long creepage distance, etc. Problems, achieve the effect of reducing the insulation level, reducing the overall height, and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

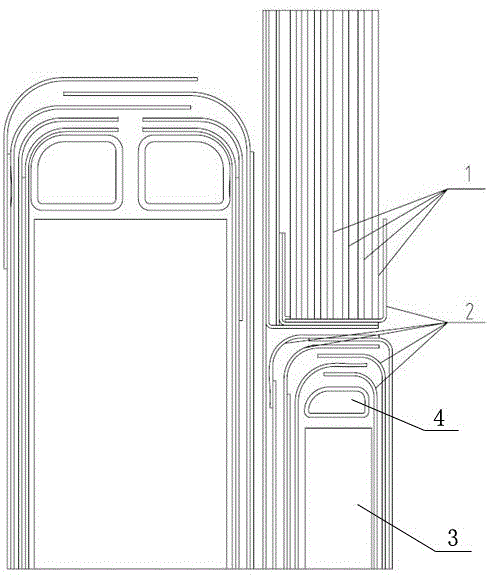

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0013] An insulating structure at the end of a voltage regulating winding for controlling creepage of a transformer, comprising a voltage regulating winding 3, a thick paper tube-stay structure 1 and a multi-layer pros and cons interlocking structure 2, which is arranged at the upper end of the voltage regulating winding 3 The multi-layer thick paper tube-stay structure 1 replaces the original end ring structure, which effectively isolates the creepage path from the high potential area of the grid side winding to the box wall through the separated end ring surface in the radial direction; The creepage distance of the terminal radial outlet to the voltage regulating winding is too long, so the following measures need to be taken to ensure the axial creepage margin;

[0014] First of all, the voltage regulating winding adopts a double-layer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com