Nano light-emitting array, manufacturing method thereof, and nano light-emitting device

A light-emitting array and nanorod array technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of limited piezoelectric sensors, limited sensor manufacturing, and insufficient application of flexible devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

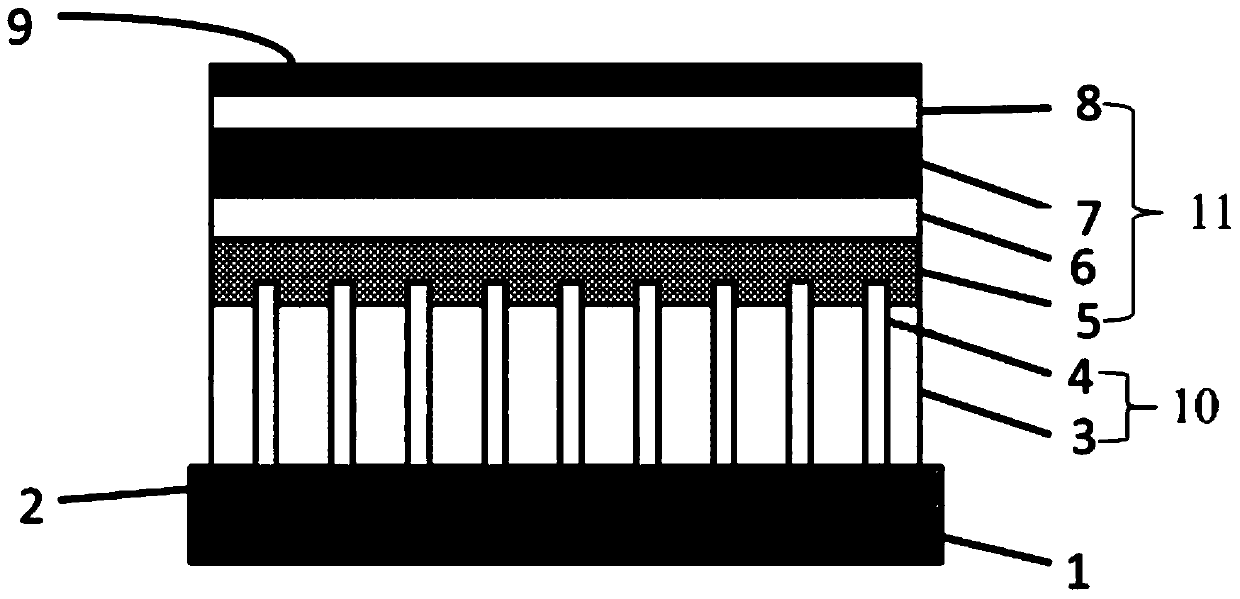

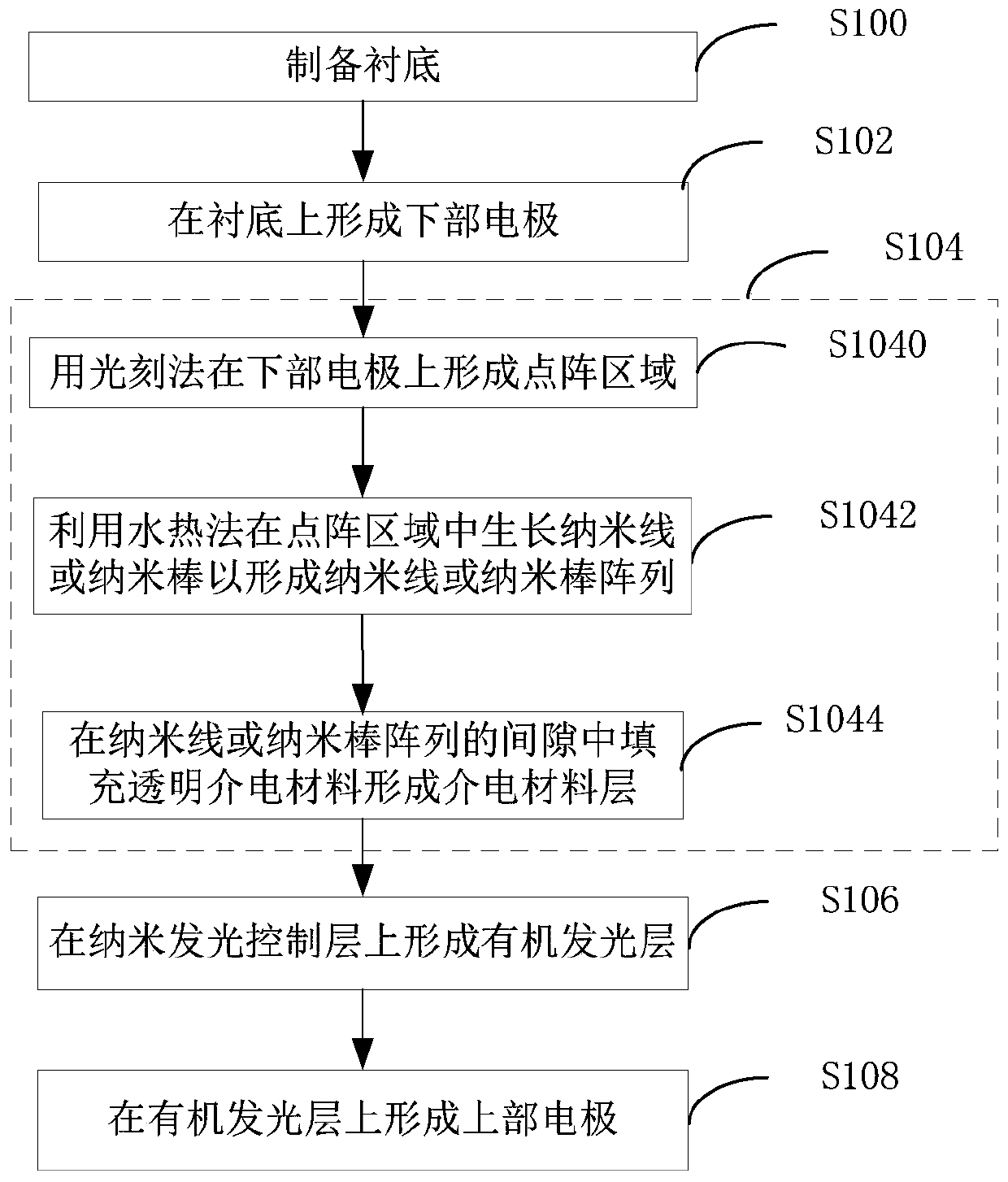

[0042] According to one embodiment of the present invention, the nano-luminescence control layer 10 may include a nanowire or nanorod array 4 and a dielectric material layer 3 formed by filling the gaps of the nanowire or nanorod array with a transparent dielectric material. , wherein the material of the nanowire or nanorod array 4 may be a piezoelectric material.

[0043] According to an embodiment of the present invention, the piezoelectric material may be a wurtzite structure material, preferably gallium nitride, gallium arsenide or zinc oxide (ZnO). The transparent dielectric material can be polymer or silicon oxide.

[0044] According to one embodiment of the present invention, in the nanowire or nanorod array 4, each array unit is a nanowire cluster or a nanorod cluster, and the diameter of each array unit may range from 100nm to 5um. The length of the nanorods can range from 1um to 10um, and the gap between two adjacent array units can range from 2um to 200um.

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com