Graphite negative electrode material for power lithium ion battery and its preparation method and application

A lithium-ion battery and graphite negative electrode technology, applied in the field of materials, can solve problems such as poor electrolyte compatibility, large irreversible capacity loss, and inability to meet power lithium ions, so as to improve the first charge and discharge efficiency and compatibility , the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

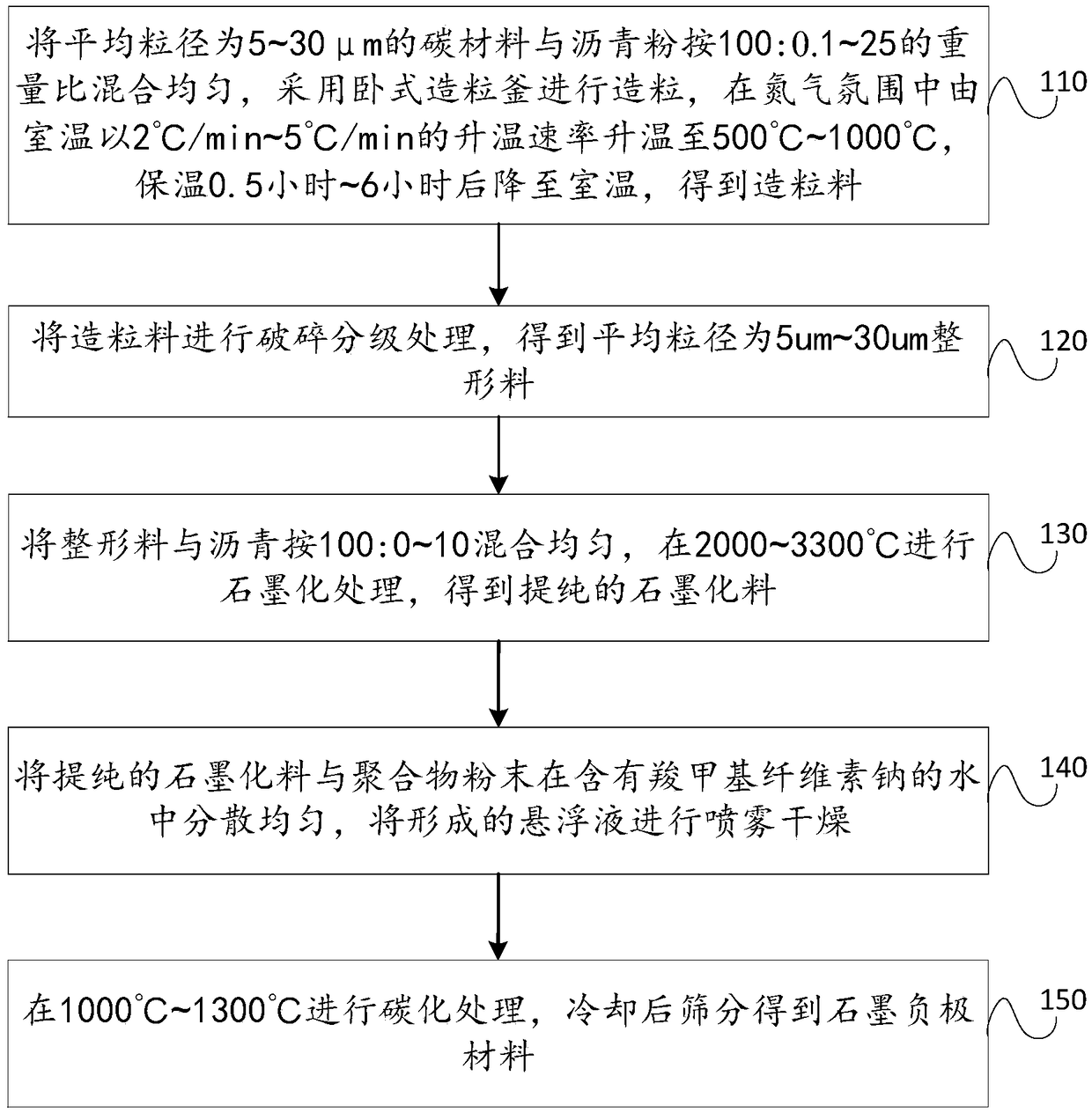

[0029] Embodiment 1 of the present invention provides a method for preparing a graphite negative electrode material for a power lithium-ion battery, comprising the following steps, specifically as figure 1 shown.

[0030] Step 110, uniformly mix carbon materials with an average particle size of 5-30 μm and pitch powder in a weight ratio of 100:0.1-25, use a horizontal granulation kettle to granulate, and granulate at room temperature at 2°C / min in a nitrogen atmosphere. Raise the temperature to 500-1000°C at a heating rate of ~5°C / min, keep it warm for 0.5-6 hours and then lower it to room temperature to obtain pellets;

[0031] Among them, the carbon material includes one or more of graphitized mesophase carbon microspheres, petroleum coke, pitch coke, needle coke or coke; the pitch includes one or more of low-temperature pitch, medium-temperature pitch or high-temperature pitch ; The polymer includes one or more mixtures of phenolic resin, polyvinylidene fluoride, polypyrro...

Embodiment 2

[0047] Step 1: Mix petroleum coke with an average particle size of 11 μm and medium-temperature pitch powder in a weight ratio of 100:9, and then use a horizontal granulation kettle for granulation. The heating rate of the granulation kettle is 5°C / min. Raise from room temperature to 800°C, keep warm for 2 hours, and then lower to room temperature to obtain granulated material;

[0048] Step 2: Pass the granulated material through a shaping classifier for crushing and grading treatment to obtain a granulated material with an average particle size of 14um;

[0049] Step 3: Mix the shaping material and asphalt uniformly at a ratio of 100:5. The asphalt is composed of 60% low-temperature asphalt and 40% high-temperature asphalt, and then use the ventilated graphitization process at 2000°C to obtain a purified graphitized material;

[0050] Step 4: Disperse the obtained purified graphitized material and phenolic resin powder evenly in water containing CMC-Na anti-precipitating agent...

Embodiment 3

[0054] Step 1: Mix the carbon material with an average particle size of 5 μm and the high-temperature pitch powder in a weight ratio of 100:16. The carbon material is composed of 20% petroleum coke and 80% pitch coke, and then use a horizontal granulation kettle to granulate. The heating rate of the granulation kettle was 4°C / min, and it was raised from room temperature to 1000°C in a nitrogen atmosphere, kept for 6 hours, and then lowered to room temperature to obtain granulated materials;

[0055] Step 2: Pass the granulated material through a shaping classifier for crushing and grading treatment to obtain a granulated material with an average particle size of 17um;

[0056] Step 3: Directly treat the reshaping material at 3300°C with a ventilated graphitization process to obtain a purified graphitized material;

[0057] Step 4: Disperse the obtained purified graphitized material and polyvinylidene fluoride powder evenly in water containing CMC-Na anti-precipitation agent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com