Self-locking U-shaped wire clamp

A U-shaped, wire clip technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of loosening, binding method and binding tightness without a unified standard, large randomness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A self-locking fastening clamp of the present invention will be further described below in conjunction with the accompanying drawings:

[0022] It should be noted that the terms "upper", "lower", "front", "rear" and similar expressions used in this specification are only for the purpose of illustration, and are determined according to the actual situation in the embodiment; "Porcelain Lu" can be selected from the current common street code porcelain or similar structures.

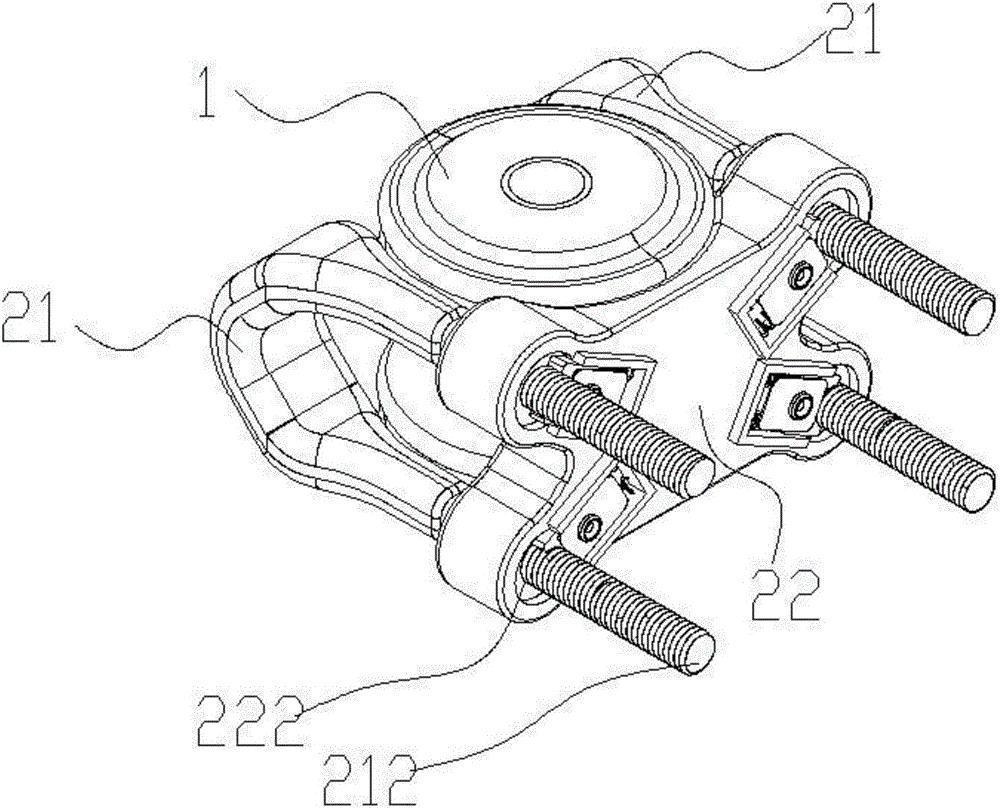

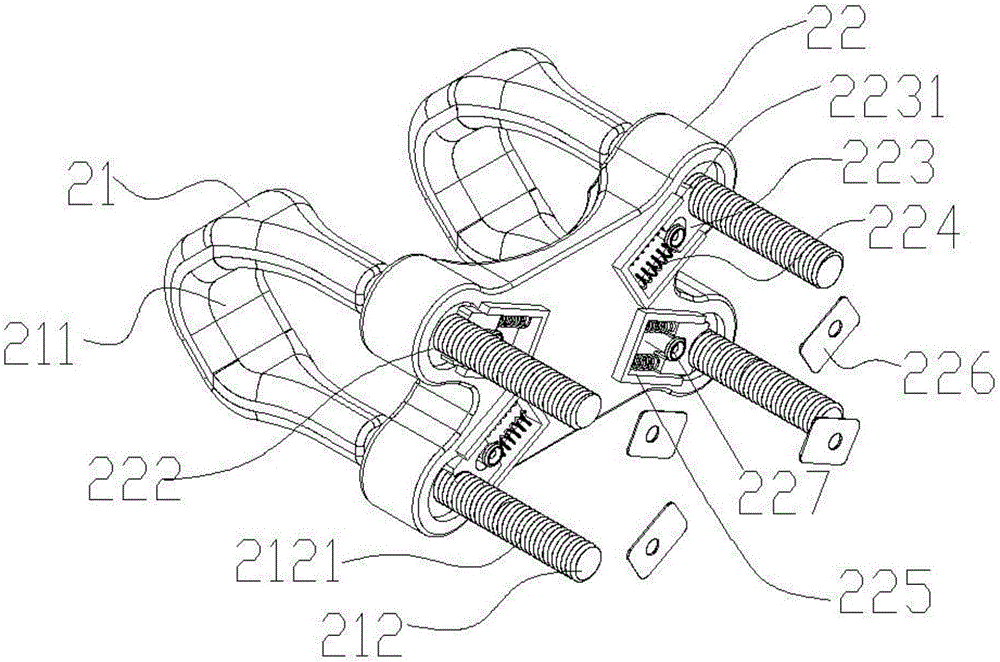

[0023] Such as Figure 1-2 As shown, a self-locking U-shaped wire clip includes a splint 22 and at least two U-shaped clips 21. The bending part of the U-shaped clip 21 is a clamping part 211, and the rods on both sides are locking rods 212. The splint 22 There are at least two pairs of locking holes 222 corresponding to the locking rods 212, at least two U-shaped clamps 21 are parallel and the locking rods 212 are vertically passed through the locking holes 222 on the splint 22 respectively. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com