Adhesive composition, adhesive using same, and adhesive for polarizing plate

A technology of adhesives and compositions, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of lack of dimensional stability, dimensional changes, etc., and achieve excellent transparency, adhesiveness, etc. Excellent adhesion and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16、 comparative example 1~9

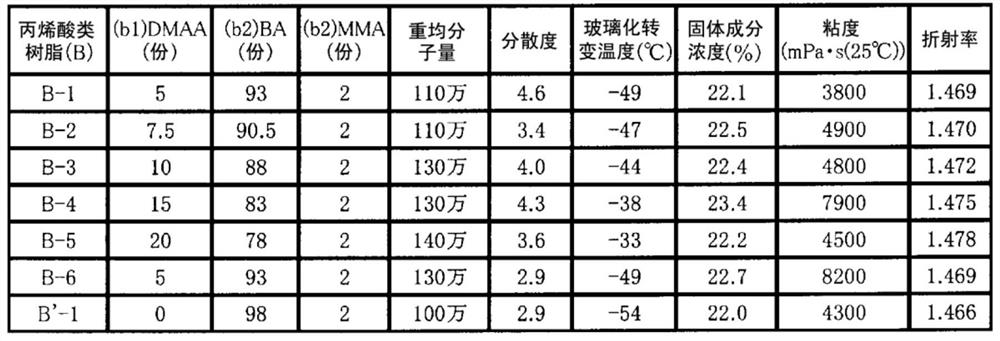

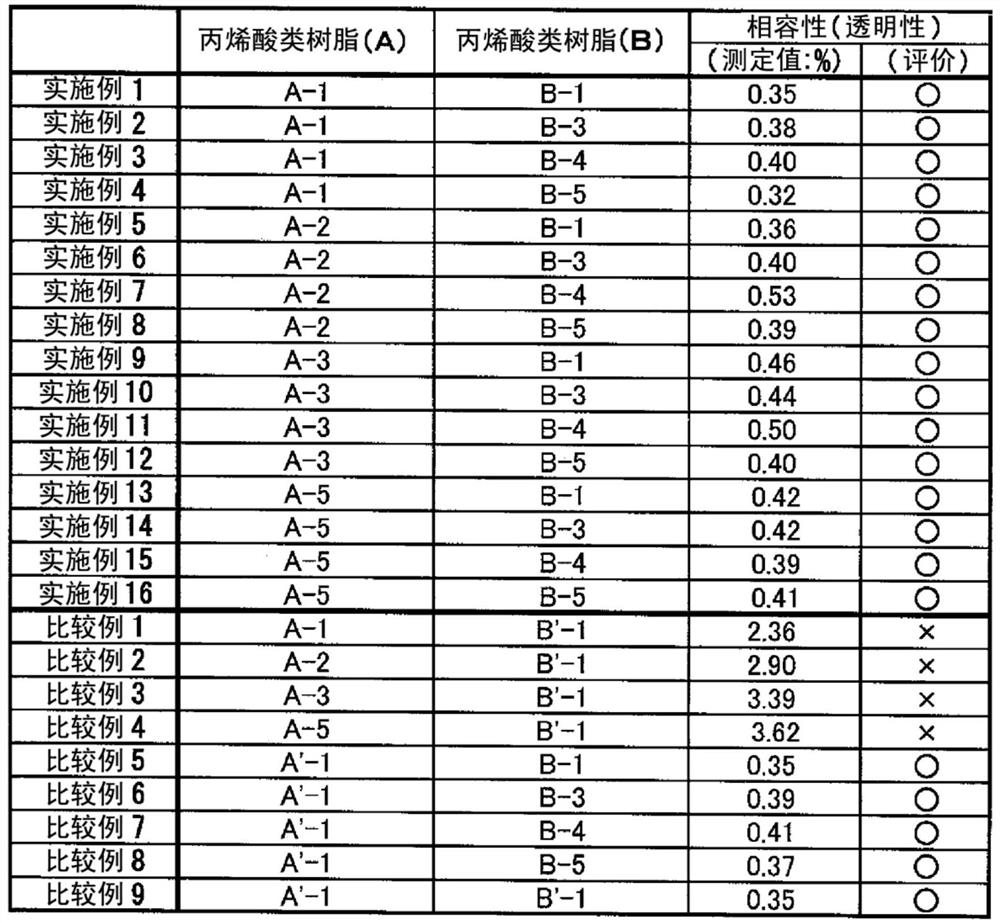

[0218]

[0219] In the combination described in Table 3, the acrylic resin (A) and the acrylic resin (B) were blended so that the weight ratio (solid content ratio) was 1:1, and the film thickness after drying was 25 μm It was coated on light-peeling PET (manufactured by Toray Co., Ltd., "Toray lumirror SP 01": thickness 38 μm) using the method. After drying at 100°C for 3 minutes, paste it on an alkali-free glass (manufactured by Corning Incorporated, "EAGLE XG": thickness 1.1mm), remove the diaphragm, and use a haze meter "HAZE MATER NDH2000" (Nippon Denshoku Co., Ltd.), and haze (%) was measured, and compatibility (transparency) was evaluated. In addition, this machine complies with JIS K7361-1. The evaluation criteria are as follows. The results are shown in Table 3.

[0220] (Evaluation)

[0221] ○···Haze less than 1%

[0222] ×···Haze is 1% or more

[0223] [table 3]

[0224] table 3

[0225]

[0226] [Crosslinking agent (C)]

[0227] As the crosslinking ag...

Embodiment 17~30

[0238] [Examples 17-30, Comparative Examples 10-15]

[0239] The ingredients prepared and prepared as above were mixed in the ratios shown in the following Table 4 to prepare an adhesive composition as an adhesive forming material, which was diluted with ethyl acetate (viscosity [500 to 10000mPa·s (25°C)]) to prepare an adhesive composition solution.

[0240] Next, the adhesive composition solutions of Examples 17 to 30 and Comparative Examples 10 to 15 were applied to a polyester-based release sheet so that the thickness after drying became 25 μm, and dried at 100° C. for 3 minutes. The formed adhesive composition layer was transferred to a polarizing plate (protective film: TAC film manufactured by Fujifilm Corporation), and aged at 23° C. and 65% RH for 7 days to obtain a polarized plate with an adhesive layer. plate.

[0241] In addition, the said polarizing plate was cut and used so that it may become 0 degree|times with respect to a stretching axis.

[0242] Using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com