Hydraulic fluids in plastic injection molding processes

A technology of hydraulic fluid and injection molding, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., and can solve problems such as not touching hydraulic fluid

Active Publication Date: 2017-05-10

EVONIK OPERATIONS GMBH

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, none of these concepts touches the hydraulic fluid used in this

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0059] The invention is further illustrated in the following non-limiting examples and comparative examples (reference oils). The following examples are used to further explain preferred embodiments according to the present invention, but are not intended to limit the present invention. All results are shown in Table 1 and Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Login to View More

Abstract

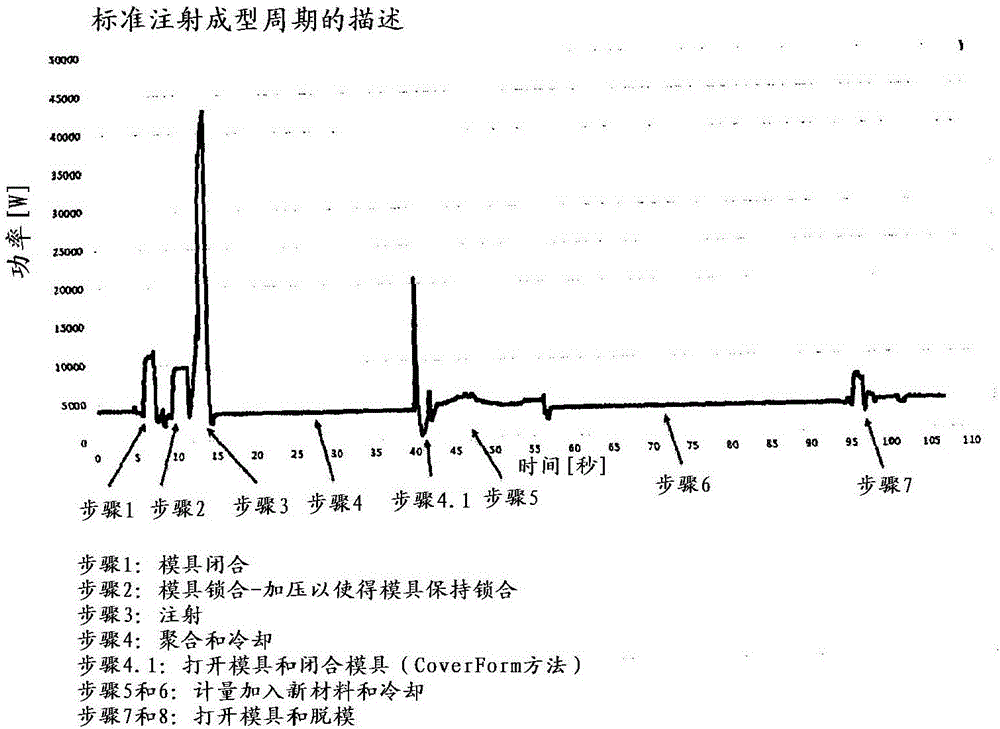

The present invention relates to the use of hydraulic fluids in plastic injection molding processes. Thereby it was surprisingly found that the use of hydraulic fluids with the right combination of physical parameters like the viscosity grade, the viscosity index, the density and the dispersancy allows for significant energy savings in plastic injection molding processes (PIM). The PIM process is an industrial process to manufacture plastic parts at well controlled temperatures, pressures and cycle times. The energy consumption of the process became more important over the last years, however, other parameters like process stability and accuracy of plastic part parameters as well as machine protection and long oil drain intervals have to be satisfying.

Description

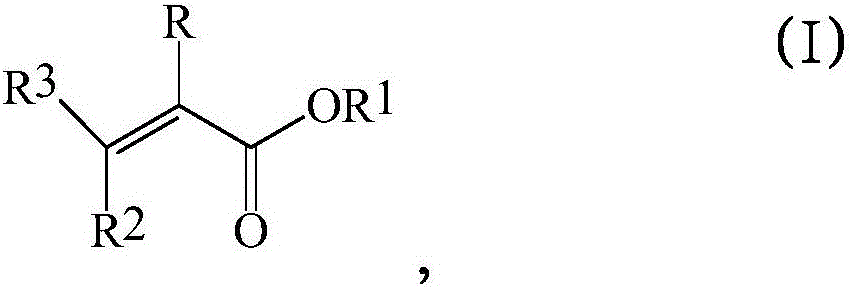

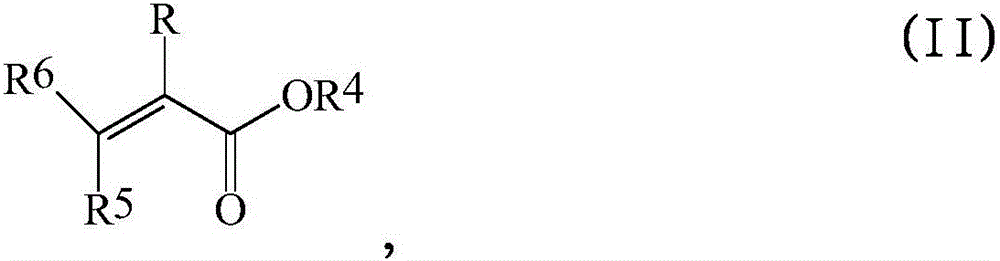

technical field [0001] The present invention relates to the use of hydraulic fluids in plastic injection molding processes. It has thus been unexpectedly found that the use of hydraulic fluids with the right combination of physical parameters such as viscosity grade, viscosity index, density and dispersibility allows significant energy savings in the plastic injection molding process (PIM). The PIM method is an industrial method of manufacturing plastic parts under well-controlled temperature, pressure and cycle time. Over the past few years, the energy consumption of the described method has become more important, however, other parameters such as process stability and precision of the plastic component parameters as well as mechanical protection and long oil change intervals must be satisfactory. Background technique [0002] Injection molding is a manufacturing method used to produce parts by injecting material into a mold under well-controlled temperature, pressure and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M149/06C10N20/02C10N30/00C10N30/02C10N40/08

CPCC10M149/06C10M2209/084C10N2030/00C10N2020/02C10N2030/02C10N2030/54C10N2040/08C10M2209/086C10M2217/02C10M2217/028C10M2217/023C10M2217/024C10N2020/04C10N2030/06C10N2030/10C10N2030/12C10N2030/18C10M145/14

Inventor F·劳特瓦瑟F-O·玛灵R·克尔博T·巴特尔斯T·施梅尔S·麦尔M·阿利伯特

Owner EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com