Heat-treated steel product having high strength and excellent chemical conversion processability, and manufacturing method for same

A technology for chemical conversion treatment and heat treatment of steel, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of poor adhesion between steel and coating film, reduced corrosion resistance, etc. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] In order to confirm the effect of the present invention, an electric-welded steel pipe (40 mm×40 mm×1.6 mm in thickness) having a rectangular cross-section having the chemical composition shown in Table 1 was prepared as a raw material.

[0048] Table 1 (% by mass, balance: Fe and unavoidable impurities)

[0049] C Si mn P S sol.Al N Cr Ti Nb B 0.22 0.20 0.75 0.014 0.003 0.04 0.004 0.30 0.030 0.025 0.015

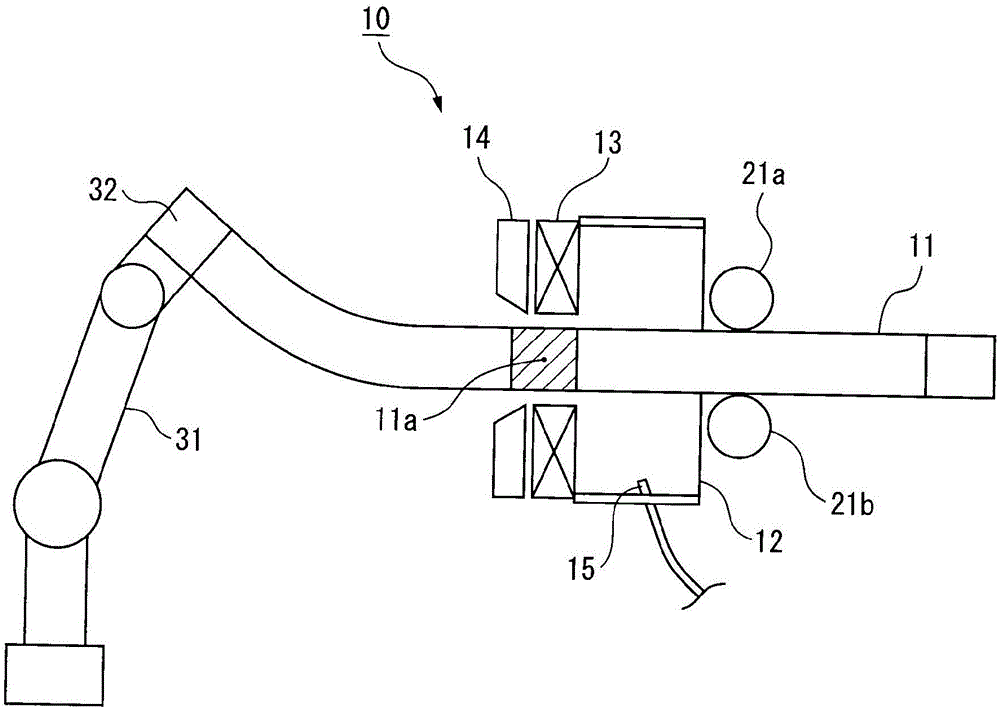

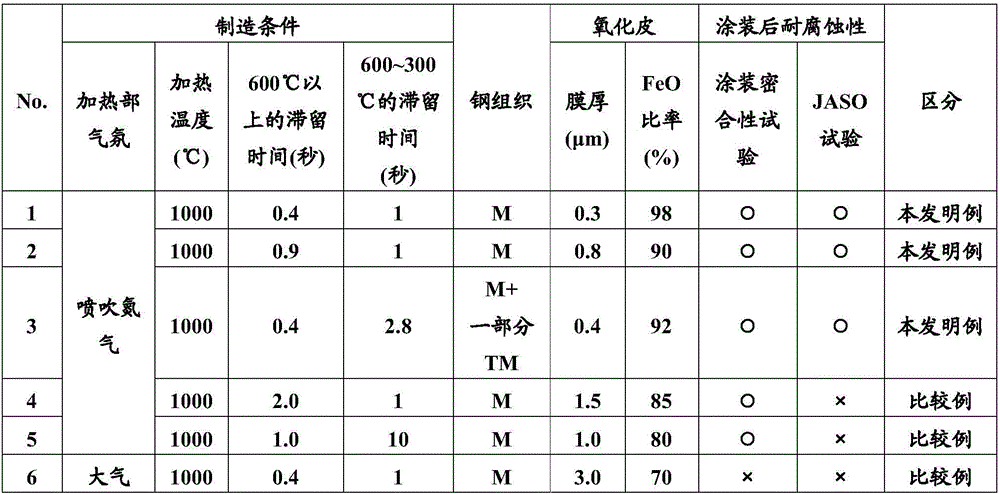

[0050] The raw material of the steel pipe is used figure 1 The shown hot three-dimensional bending processing device is heat-treated under the conditions shown in Table 2 to produce heat-treated steel products. In addition, about No. 3 of Table 2, tempering was implemented by the control of the cooling process of a hot-state three-dimensional bending processing apparatus.

[0051] For the obtained heat-treated steel product, after corroding the cross-sectional structure with a nital etching solution, four fields of view were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com