High-strength cold-rolled steel sheet superior in chemical conversion treatability and manufacturing method thereof

A technology for chemical conversion treatment and cold-rolled steel sheets, applied in the field of cold-rolled steel sheets, can solve the problems of inability to obtain high-strength steel sheets, limited heating time, and inability to ensure chemical conversion treatment, and achieve excellent chemical conversion treatment, easy to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

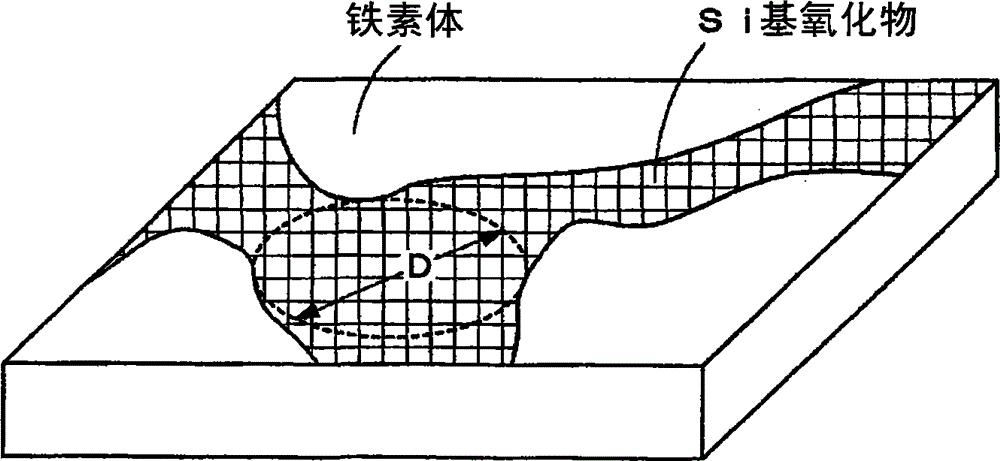

Image

Examples

Embodiment 1

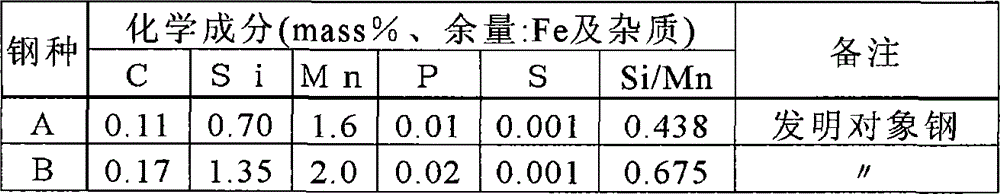

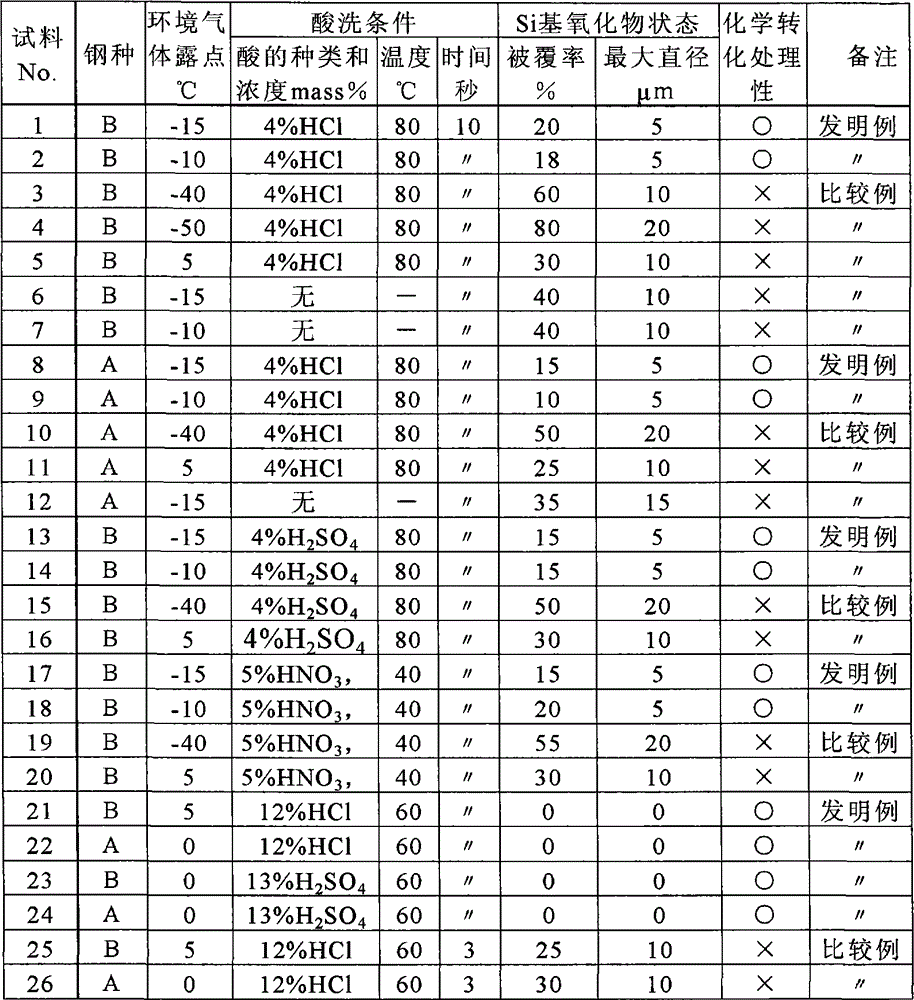

[0046] Steel materials A and B shown in Table 1 were melted in a converter, and slabs were produced by continuous casting. This slab was heated and hot rolled to a thickness of 2.5 mm. Thereafter, pickling was performed, and cold rolling was performed to a thickness of 1.2 mm. After cold rolling, annealing was performed on a continuous annealing line at 850° C. for about 80 seconds, water quenching was performed, pickling was performed under the conditions shown in Table 2, and tempering was performed thereafter. Tempering is held at 200°C for about 140 seconds for the steel material A, and about 140 seconds for the steel material B at 300°C. The ambient gas during annealing and tempering was hydrogen-nitrogen mixed gas (hydrogen concentration: 3 vol%), and the dew point was adjusted as shown in Table 2. As a result of measuring the tensile strength of the cold-rolled steel sheets produced in this way, the steel sheet of the steel type A was about 780 MPa, and the steel shee...

Embodiment 2

[0055] Steel materials 1 to 14 shown in Table 3 were melted in a converter, and slabs were produced by continuous casting. This slab was heated and hot rolled to a thickness of 2.5 mm. Thereafter, pickling was performed, and cold rolling was performed to a thickness of 1.2 mm. After cold rolling, annealing and quenching were performed on the continuous annealing line under the annealing conditions shown in Table 4, and then tempering was performed under the tempering conditions shown in Table 4. The ambient gas during annealing and tempering was hydrogen-nitrogen mixed gas (hydrogen concentration: 3 vol%), and the dew point was adjusted as shown in Table 4. In addition, "WQ" in a table|surface represents water quenching. Furthermore, post pickling was performed under the conditions shown in Table 4, and the tensile strength (TS) was measured. As shown in Table 5, the tensile strengths of all the steel sheets of steel types 1 to 14 were 700 MPa or more. Table 5 also shows YP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com