Bearing Oil Drain Structure

一种排油结构、轴承的技术,应用在轴承、轴和轴承、轴承元件等方向,能够解决润滑油滞留、排油性能降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to the embodiments.

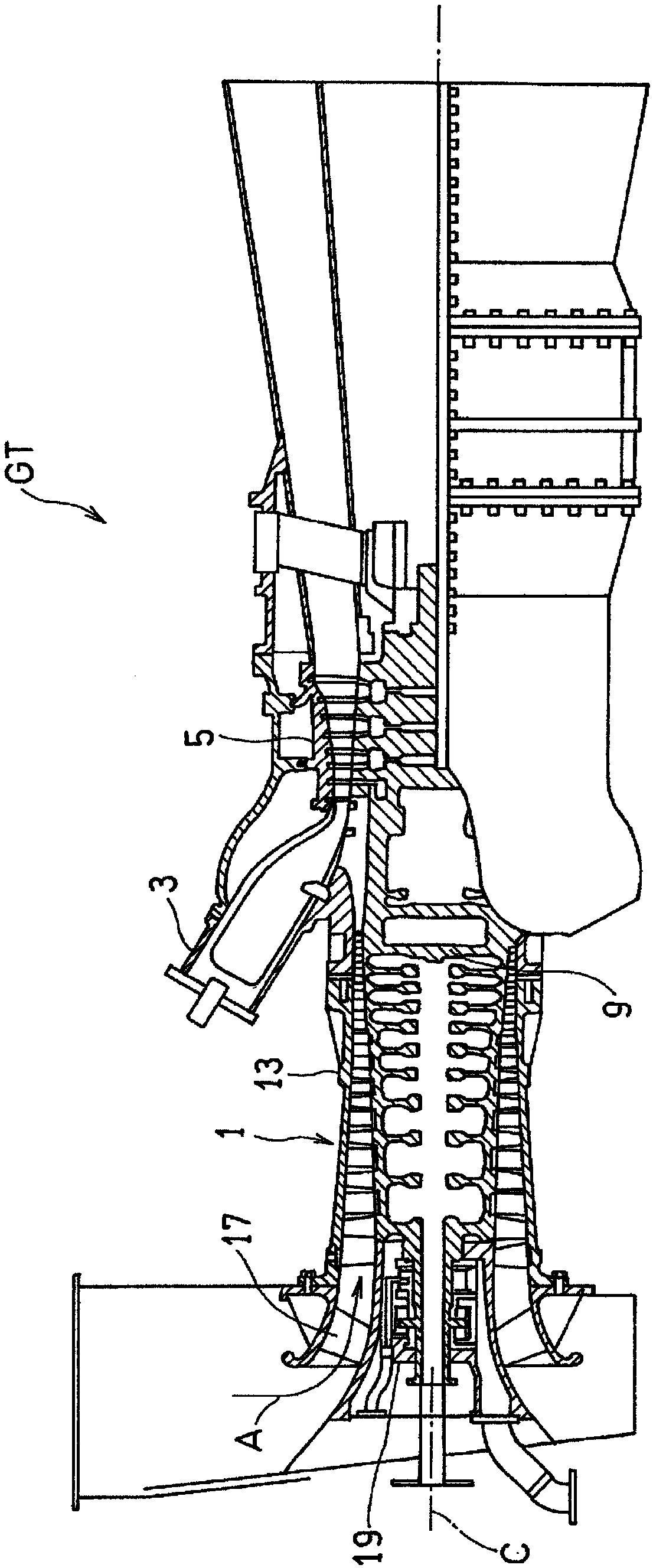

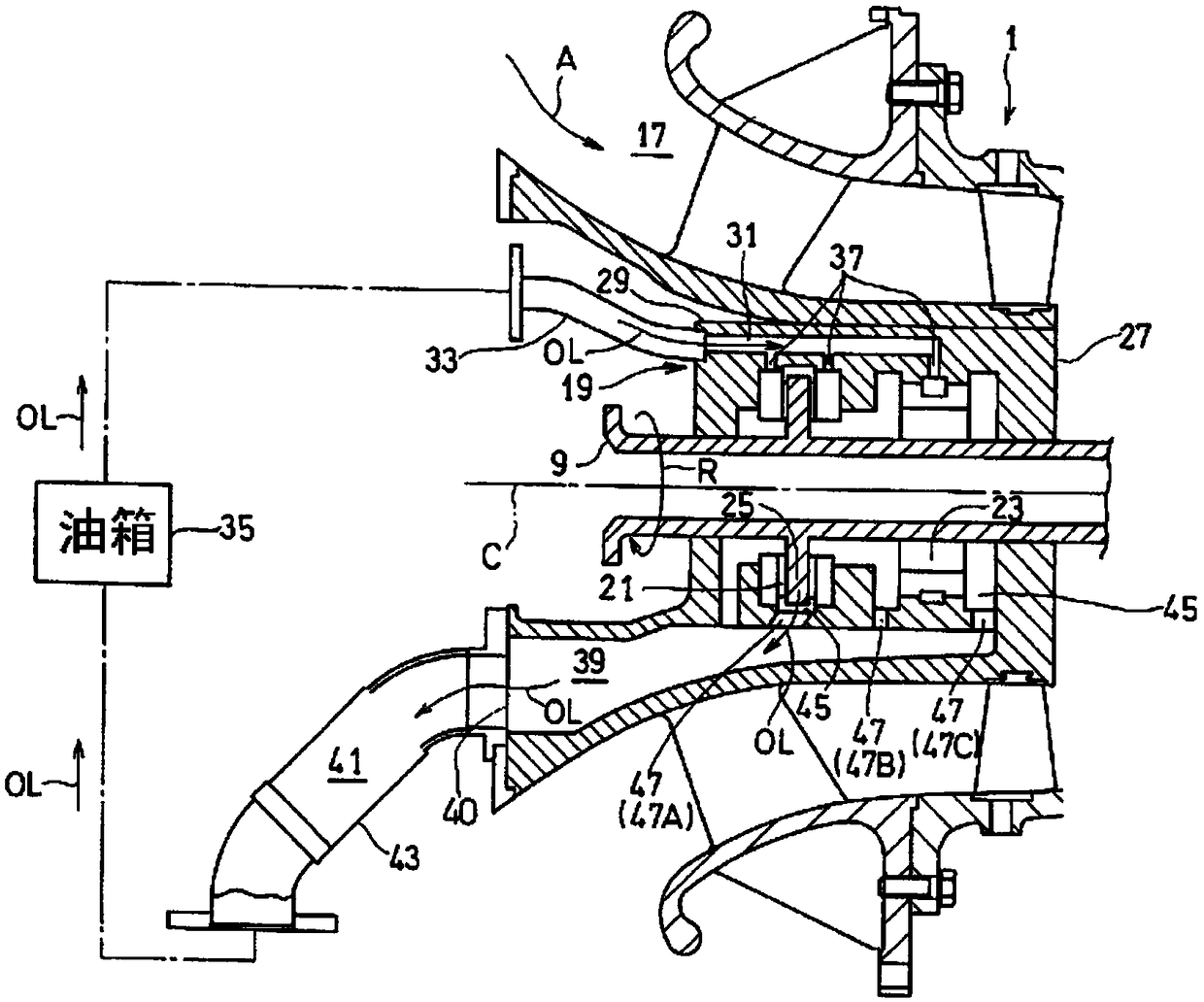

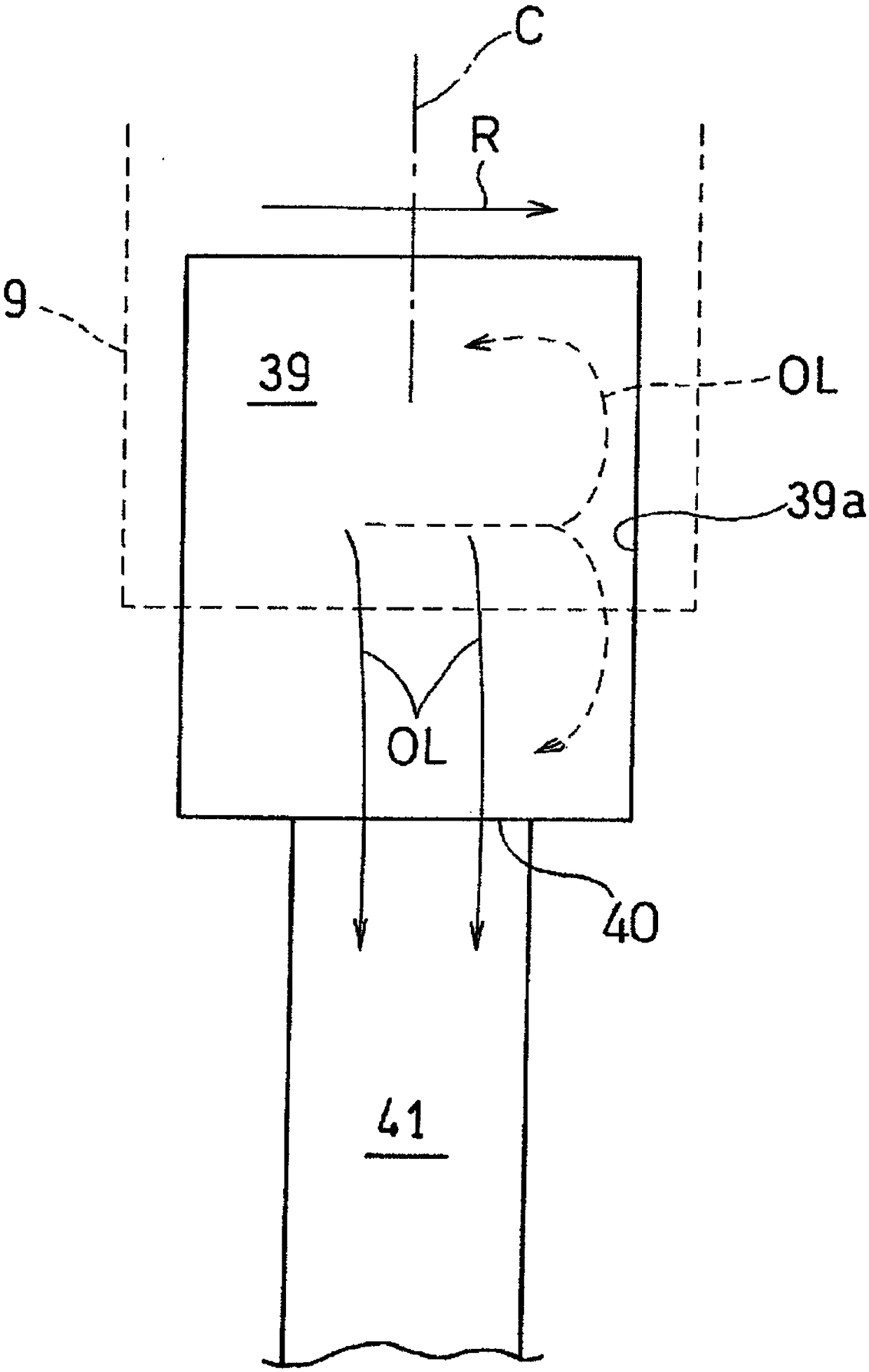

[0030] figure 1 A schematic structure of a gas turbine engine (hereinafter simply referred to as a gas turbine) GT to which an oil discharge structure of a bearing according to an embodiment of the present invention is applied is shown. The gas turbine GT compresses the air A introduced by the compressor 1, guides it to the combustor 3, injects fuel into the combustor 3 to combust it together with the air A, and drives the turbine 5 with the high-temperature and high-pressure combustion gas obtained through the combustion. The turbine 5 is connected to the compressor 1 via a rotor 9 as a rotating shaft, and the compressor 1 is driven by the turbine 5 . In the following description, the compressor 1 side in the axial center C direction of the gas turbine GT may be referred to as a "front side", and the turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com