Vehicle brake actuator

A vehicle braking and actuator technology, applied in the direction of brakes, brake actuators, transmissions, etc., can solve the problem of affecting the reliability of braking, harmful to the safety of vehicle passengers, and unsatisfactory application of electromechanical brake actuators And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

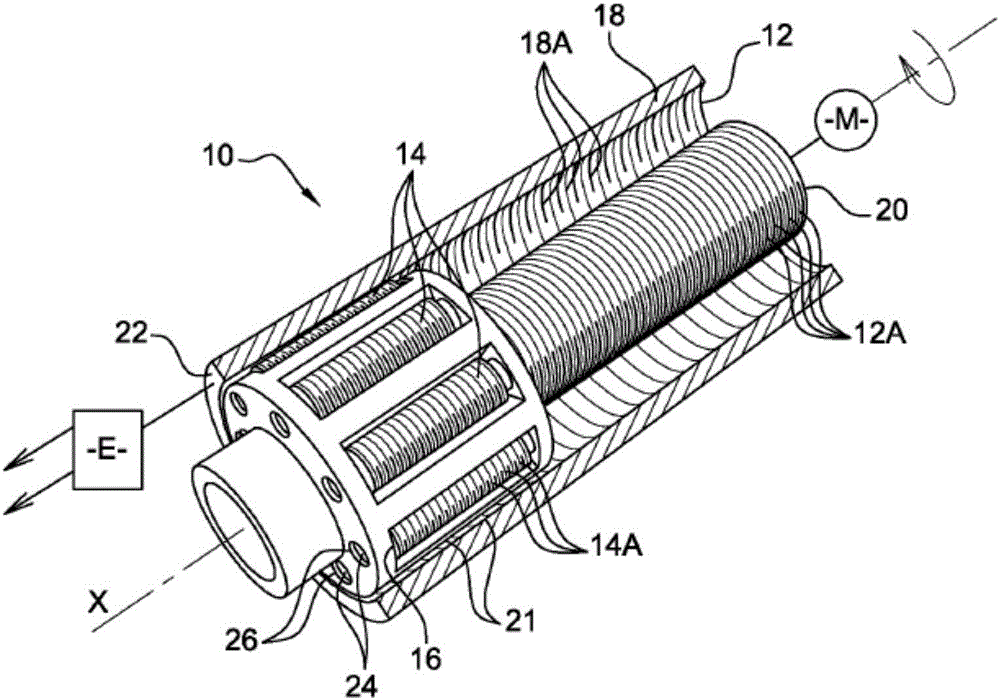

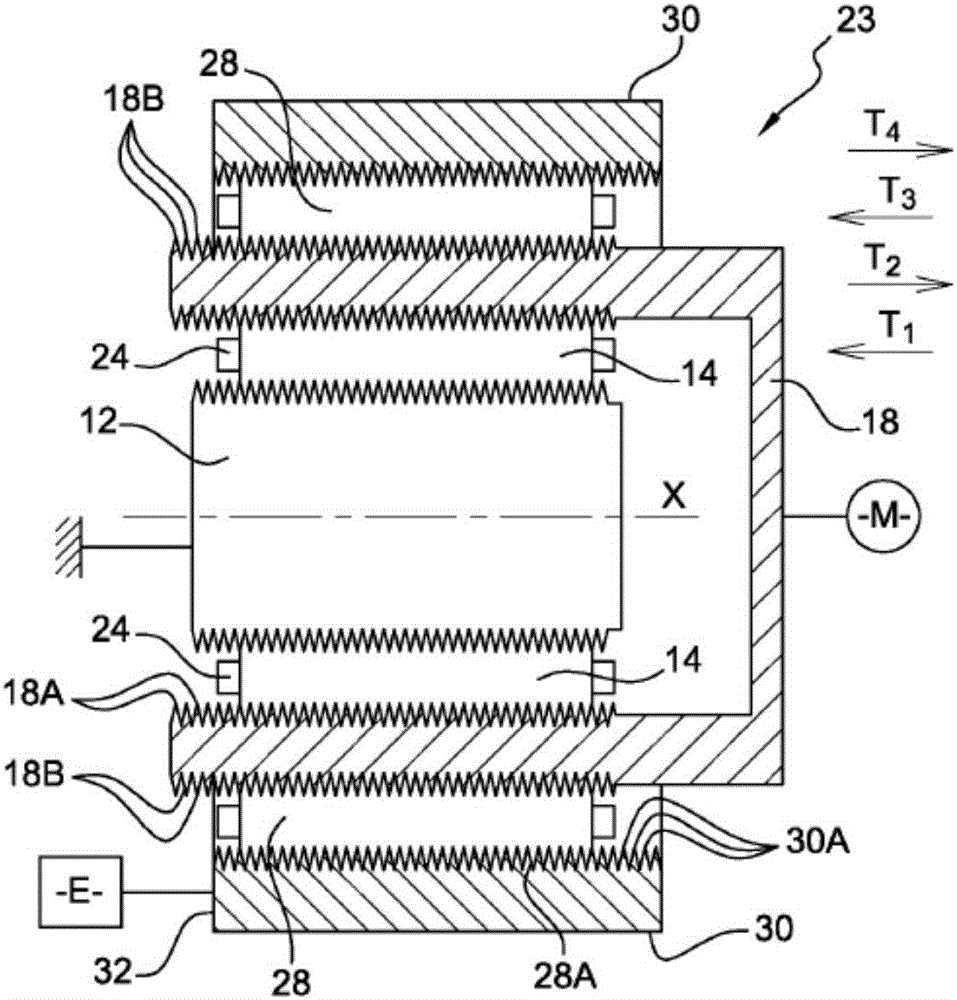

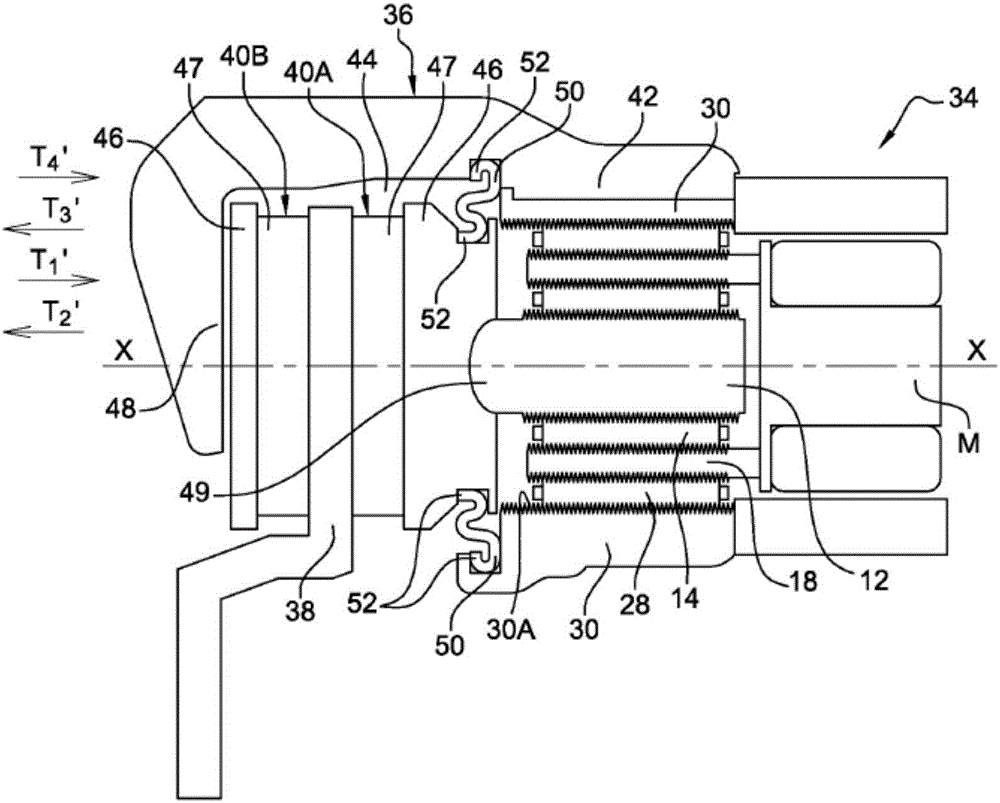

[0037] refer to figure 1 , in the brake actuator according to the present invention, the reducer 10 includes an internal screw 12 , a roller 14 arranged around the screw, a frame 16 for carrying the roller, and a casing 18 .

[0038] The screw 12 has three threads 12A facing the same first direction. One end 20 of the screw 12 is arranged to be fixed rigidly to a rotary drive, such as the motor M of the actuator. Thus, the retarder is provided to be electrically controlled. The other end of the screw comprises a smooth and hollow free edge.

[0039] The roller 14 is threaded and has a longitudinal axis parallel to the axis X of the screw. These rollers each have a single flight 14A that directly engages the flight 12A of the screw. The flight 14A of each roller 14 faces in the opposite direction to the flight 12A of the screw 12 .

[0040] The frame 16 for carrying the rollers 14 has a cylindrical shape coaxial with the screw 12 and extends over a small part of the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com