Dual-type wave gear device

A technology of wave gear device and gear, applied in the direction of gear transmission device, transmission device, hoisting device, etc., can solve the problems of low speed ratio and difficulty, and achieve the effect of improving the fatigue strength of the bottom of the tooth, improving the tooth contact and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

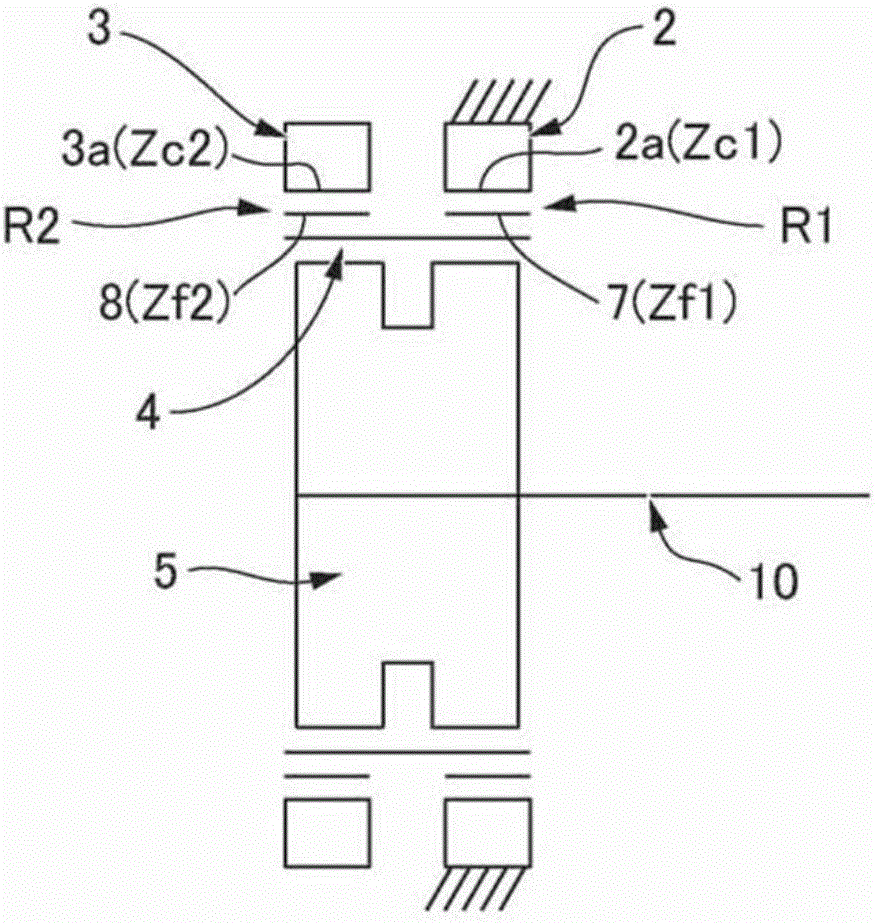

[0104] In addition, in the above-mentioned example, the first internal gear 2 is a stationary internal gear, and the second internal gear 3 is a driving internal gear. Conversely, it is also possible to make the first internal gear 2 a drive-side internal gear, and make the second internal gear 3 a stationary-side internal gear.

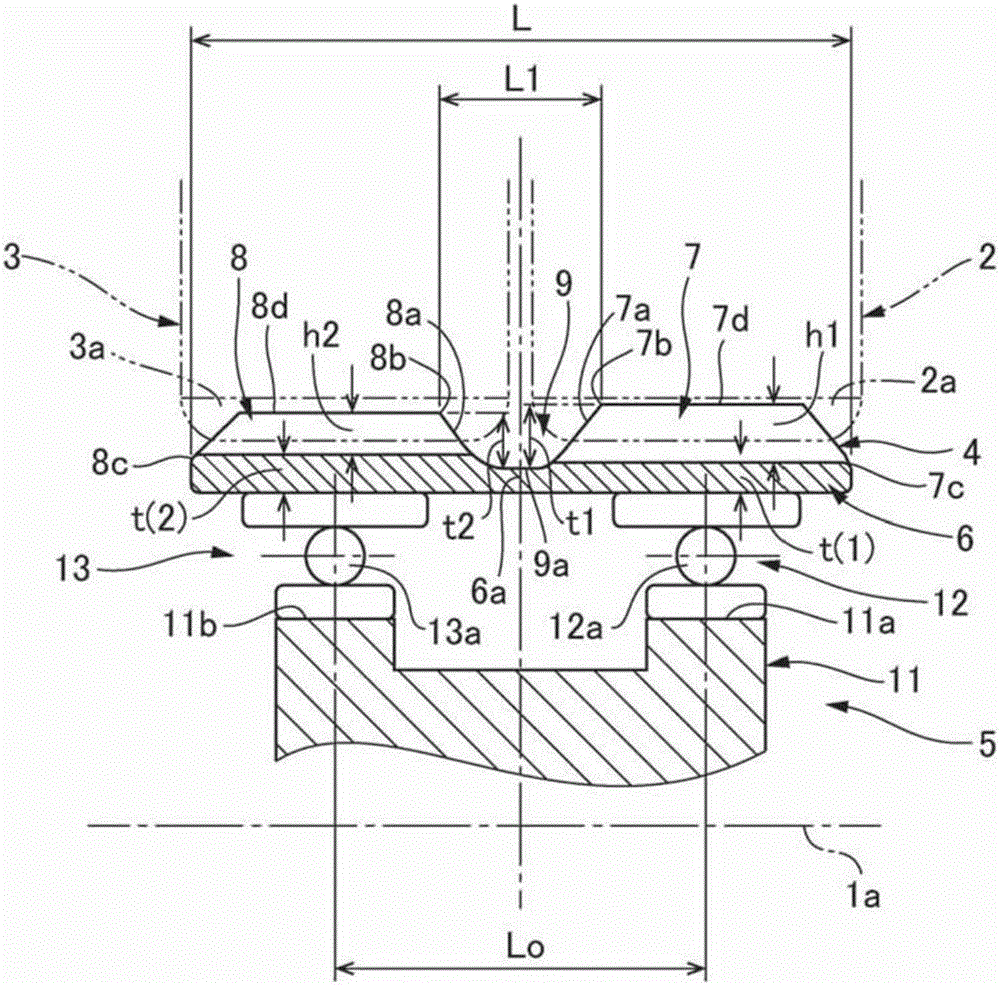

[0105] In addition, the externally toothed gear 4 can be bent and deformed by the wave generator 5 into a non-circular shape other than an ellipse, for example, a non-circular shape such as a three-lobe shape. When the number of meshing parts between the externally toothed gear and the internally toothed gear deformed into a non-circular shape is h (h: a positive integer greater than 2), the difference in the number of teeth of the two gears only needs to be set as h*p (p: positive integer) is fine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com