Corn cob biomimetic smashing soil fattening returning machine

A technology of corn cob and crushing mechanism, which is applied in agricultural machinery and tools, agriculture, shovels, etc. It can solve the problems of uneven returning to the field, large particle size of crushing, and slow decay, so as to improve the efficiency of returning fertile soil to the field and improving the crushing efficiency and quality, the effect of accelerated decay of loamy soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

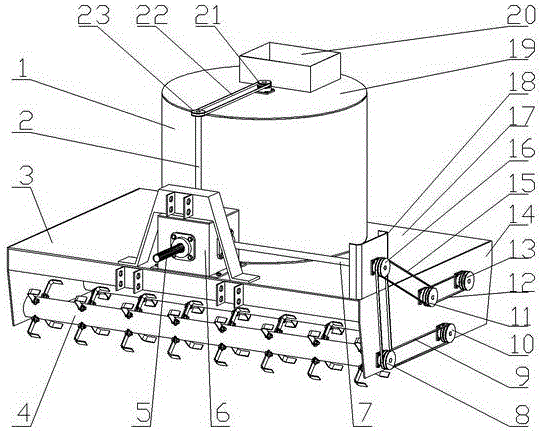

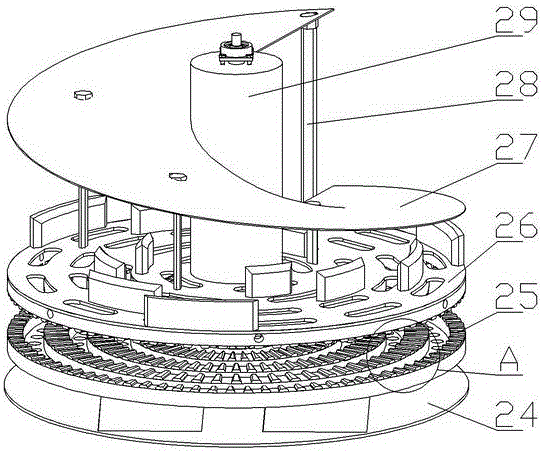

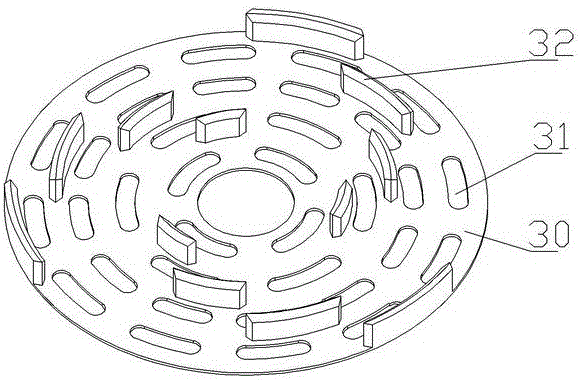

[0019] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a vertical crushing mechanism 1, a frame 3, a horizontal field returning mechanism 4 and a transmission mechanism 5, the vertical crushing mechanism 1 is fixed on the upper rear end of the frame 3, and the horizontal field returning mechanism 4 is fixed At the bottom of the frame 3; the vertical pulverizing mechanism 1 includes an organic cover 19, a feeding port 20, a bottom cover 24, a grinding cutter disc 25, a chopping cutter disc 26, a screw feeding blade 27, a vertical knife 28, a rotating shaft 29, Knife holder 30, coarse feeding port 31, arc cutter 32, fine feeding port 33 and grinding teeth 34, machine cover 19 are fixed on the outside of vertical crushing mechanism 1, feeding port 20 is fixed on the top of machine cover 19 end, the bottom cover 24 is fixed on the bottom of the machine cover 19, the grinding cutter head 25 is fixed on the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com