Centrifugal stirring optical lens polishing equipment

An optical lens, stirring technology, which is used in grinding/polishing equipment, metal processing equipment, optical surface grinders, etc., can solve the problems of no stirring mechanism and poor polishing effect, and achieve improved stability, good polishing effect, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

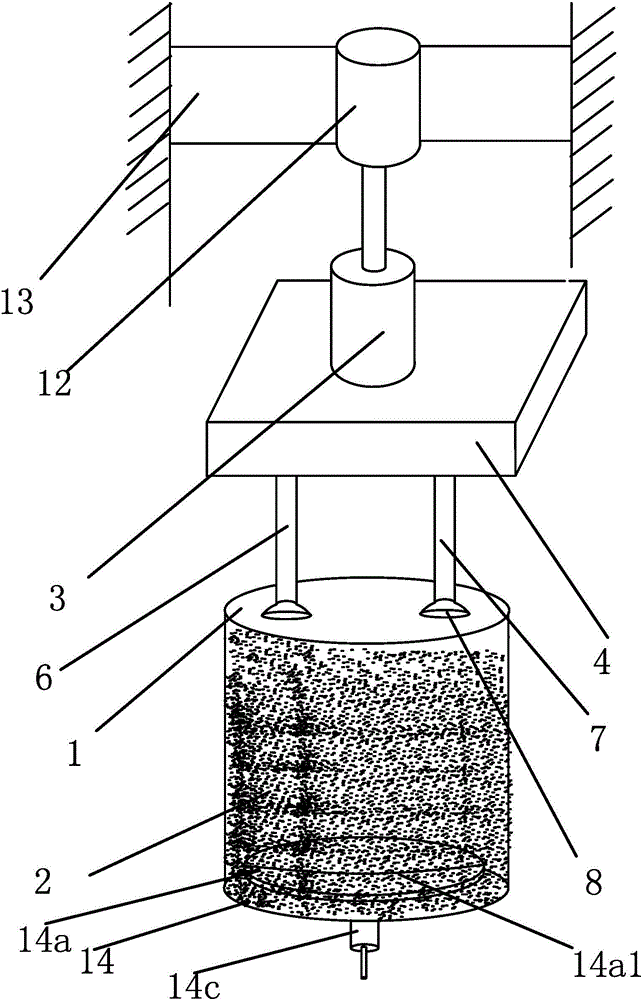

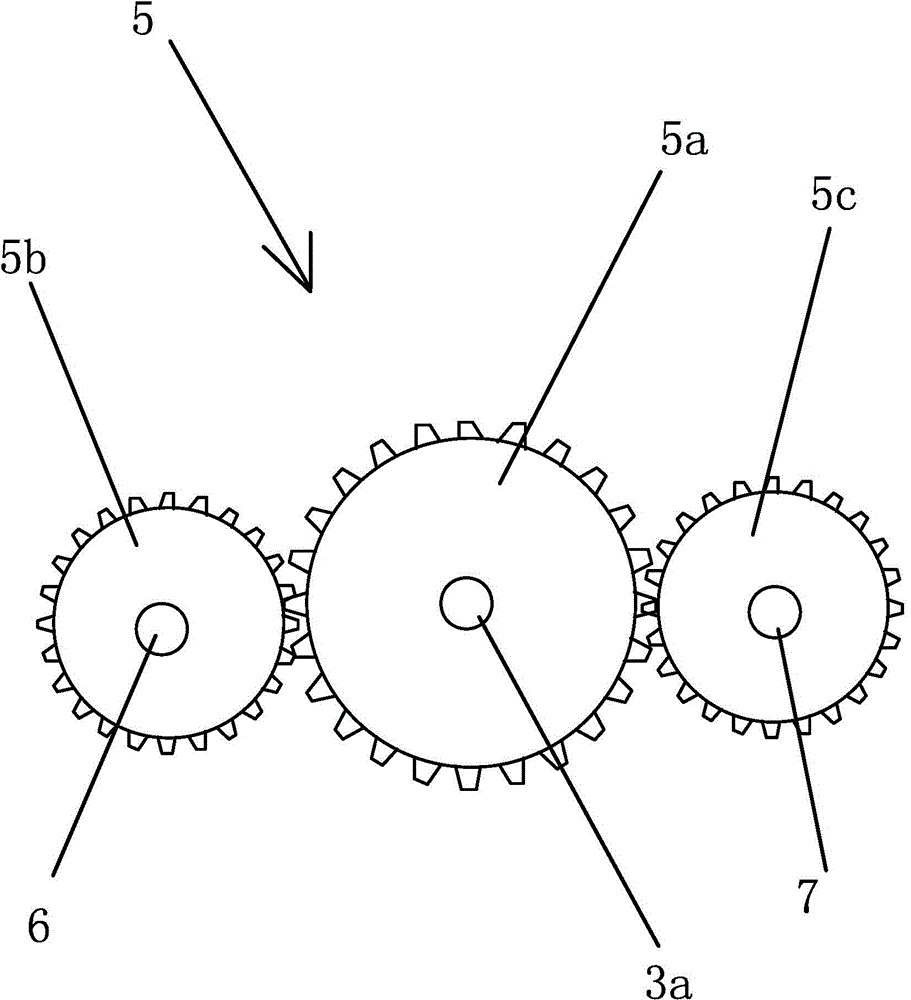

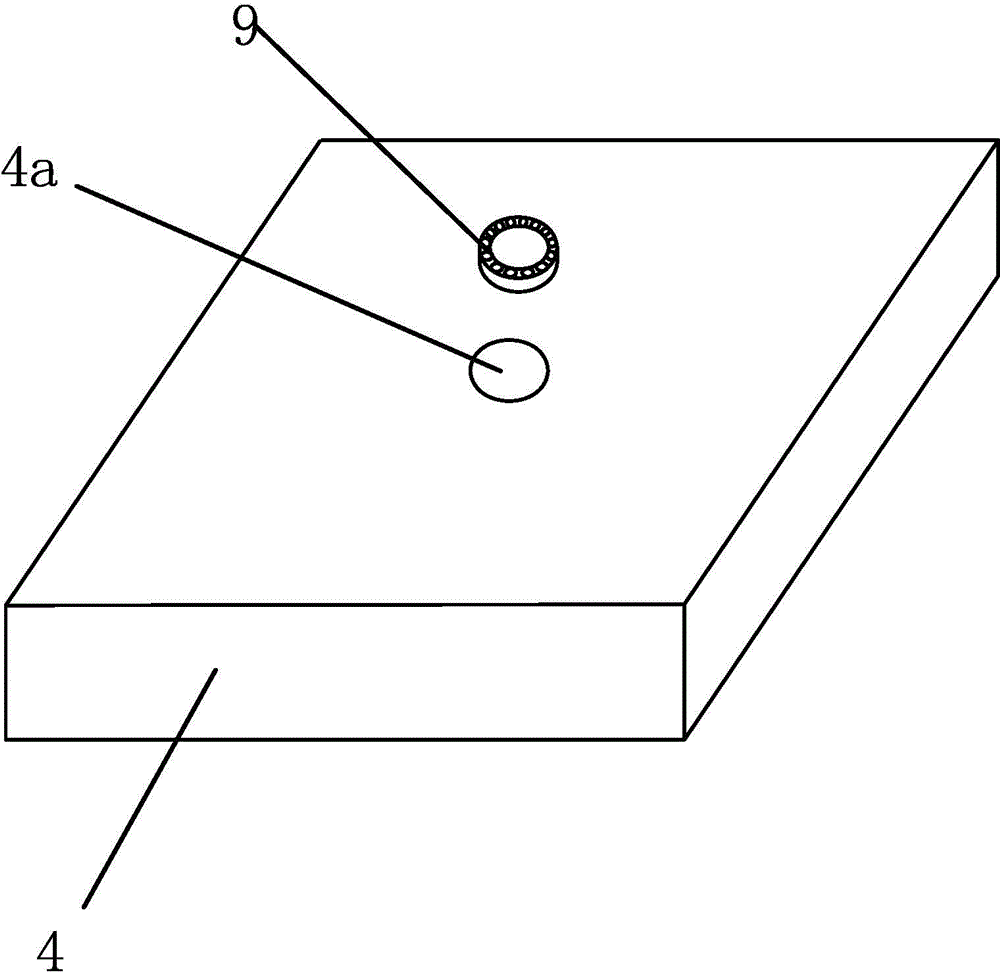

[0037] like Figure 1 to Figure 6As shown, the centrifugal stirring type optical lens polishing equipment includes a barrel-shaped processing barrel 1, which has a polishing liquid 2 in the processing barrel 1, and the polishing liquid 2 is a mixture of water and carborundum. Rotating device, rotating device comprises rotating motor one 3, and the motor rotating shaft 3a of rotating motor one 3 stretches in a square two-way box 4, and the end of motor rotating shaft 3a is connected with steering mechanism 5, and steering mechanism 5 rotates by motor rotating shaft 3a The output drives straight rod one 6 and straight rod two 7 to rotate in the opposite clockwise direction, straight rod one 6 and straight rod two 7 are arranged in parallel, the inner ends of straight rod one 6 and straight rod two 7 are connected to steering mechanism 5, and straight rod one 6 and the outer end port of straight rod two 7 are fixedly connected with suction cup 8, and steering mechanism 5 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com