Steel pipe painting equipment

A painting and equipment technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of long natural drying time, increased labor, and reduced product efficiency. Simple structure, short drying time, anti-drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

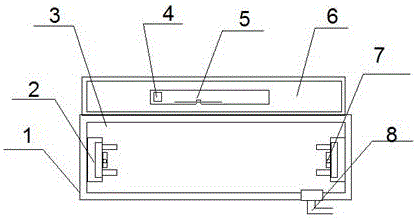

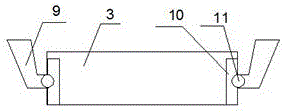

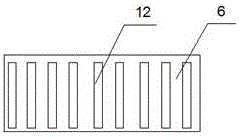

[0015] refer to figure 1 , figure 2 and image 3 The shown steel pipe painting equipment includes a steel pipe painting equipment body 1; the steel pipe painting equipment body 1 is provided with a paint tank 3; the two ends of the paint tank 3 are provided with clamping fixtures 2; The clamping fixture 2 is provided with a powerful magnet 7; the clamping fixture 2 is provided with a lifting cylinder 10; the lifting cylinder 10 is provided with a starting handle 9; the right side of the paint vat 3 A drying chamber 6 is provided; a drying heater 5 is provided in the middle of the drying chamber 6; a ventilation fan 12 is provided around the drying chamber 6.

[0016] As a preferred technical solution, the paint tank 3 is provided with a feed valve 8 .

[0017] As a preferred technical solution, a rotating lifting gear 11 is arranged in the starting handle 9 .

[0018] As a preferred technical solution, the drying heater 5 is provided with a power regulator 4 .

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com