Mechanical arm structure capable of adjusting contact force and reducing deformation influences

A mechanical arm and contact force technology, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of position deviation, mechanical arm deformation and other problems, so as to reduce the deformation amount, reduce the change of the axis angle, and improve the accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

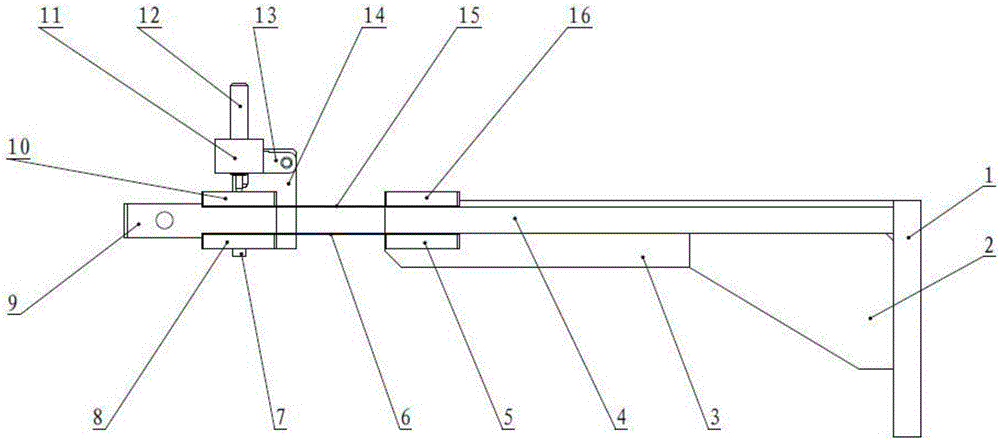

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0018] The robotic arm consists of a body, a tool unit and a plunger unit. The body includes the bottom plate of the robotic arm 1, the mounting plate of the robotic arm 4, the mounting plate of the visual device 3, the side plate and the rib 2; the tool unit includes the suction cup adapter 9, the end effector, the upper and lower springs 6, 15 and the lower pressure plate of the spring 1, 5, spring plate lower plate 2 8, spring plate upper plate 10, spring plate upper plate 2 16; the plunger unit includes a plunger 12, a plunger fixed angle seat 11, a micro switch 13, a micro switch connecting plate 14 and The supporting beams consist of 7.

[0019] Different end effectors can be selected for different operation objects, and the use of vacuum suction cups as end effectors is used as an example to illustrate.

[0020] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com