Buffer mechanism for workshop production

A buffer mechanism and workshop technology, applied in presses, metal processing, manufacturing tools, etc., can solve the problems of easy damage and deformation of the lower buffer block, high noise, etc., and achieve the effect of good buffer vibration absorption capacity, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

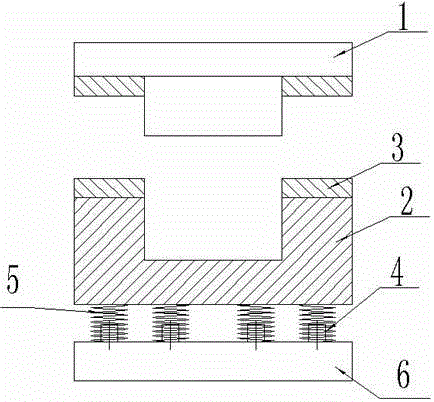

[0015] The present invention will be further described below in conjunction with the accompanying drawings. Buffer mechanism for workshop production: including upper buffer block 1, lower buffer block 2, buffer rubber pad 3 and buffer device.

[0016] Such as figure 1 As shown, the structure of the buffer mechanism for workshop production is as follows: the contact surfaces of the upper buffer block 1 and the lower buffer block 2 are respectively provided with buffer rubber pads 3, and the use of buffer rubber pads can greatly reduce the impact. The surface is also provided with a cushioning device. The buffer device is composed of several buffer shafts 4 , springs 5 and fixed bases 6 arrayed in parallel. The buffer shaft 4 is inside the through hole in the middle of the spring 5, any one end of the buffer shaft 4 is fixedly installed on the fixed base 6, any end of the spring 4 is installed on the upper surface of the fixed base 6, and the other end is installed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com