Automatic feeding device for long workpieces

An automatic feeding and strip-shaped technology, which is applied to the destacking of objects, conveyor objects, transportation and packaging, etc., can solve problems such as high labor costs, inaccurate loading or unloading positions, and reduce production costs. Achieve the effect of high production efficiency, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

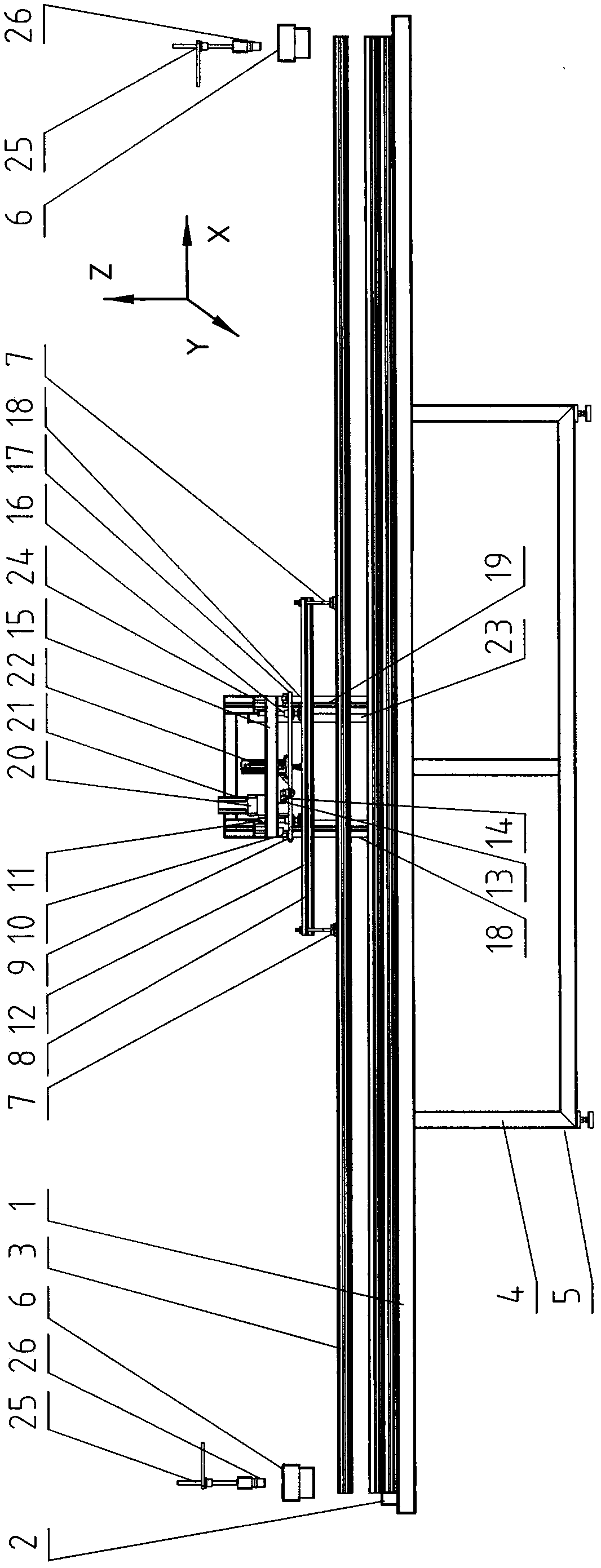

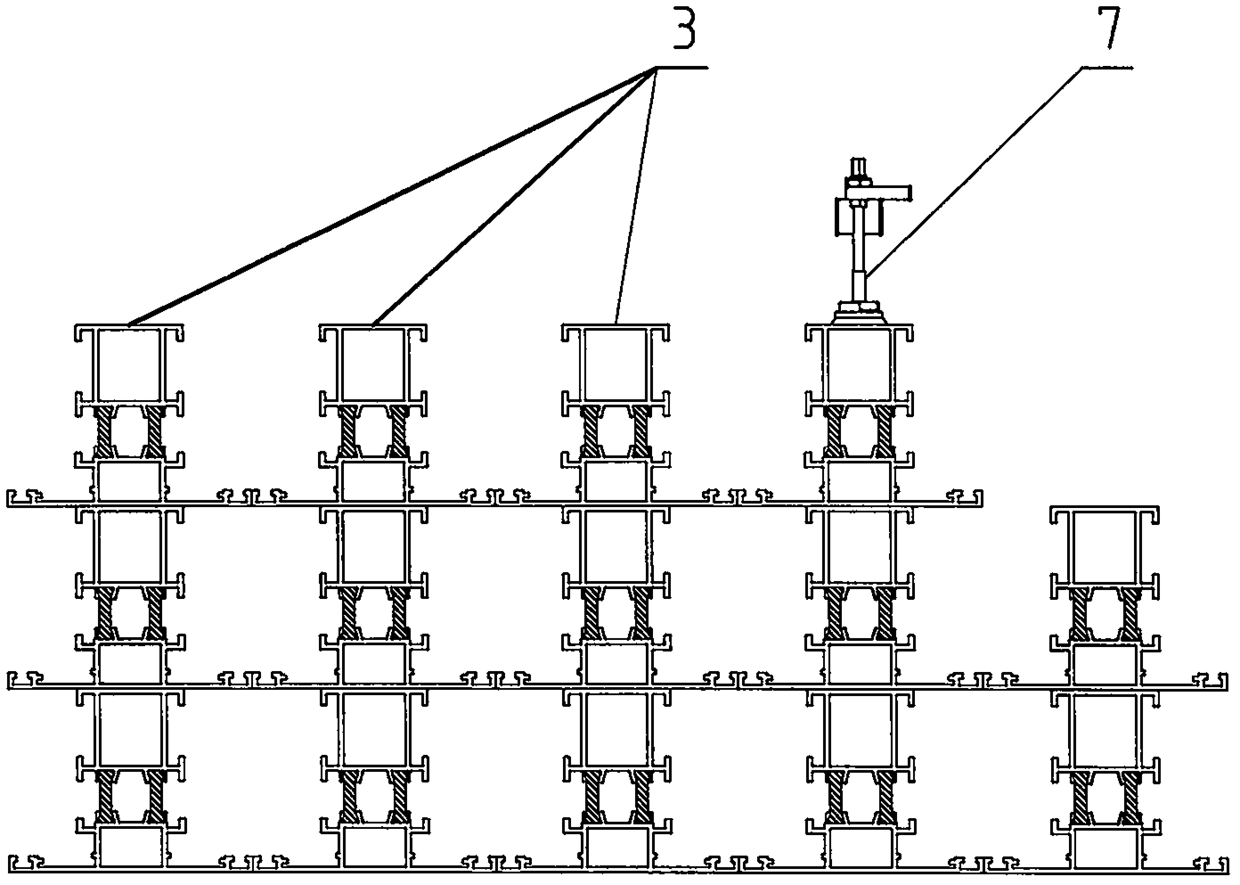

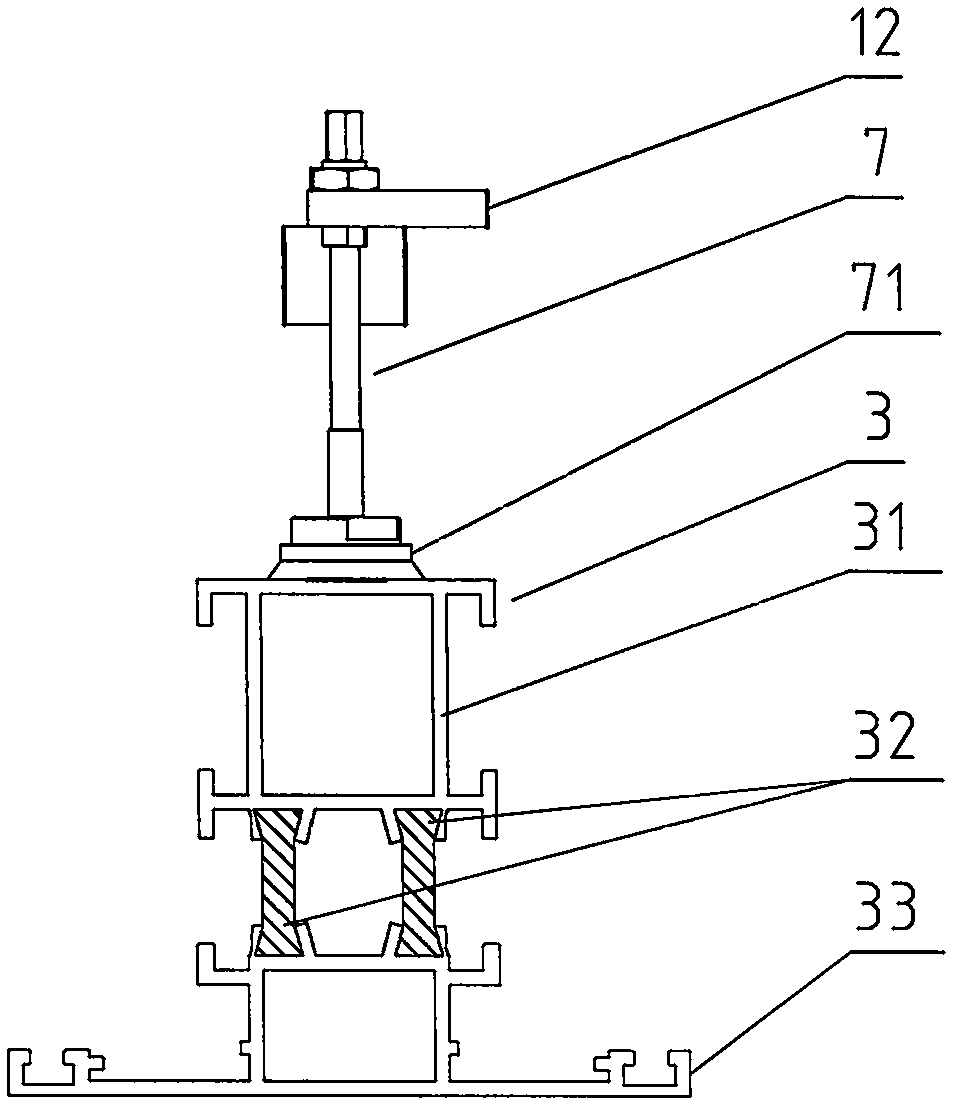

[0034] see Figure 1-10 , an automatic loading device for elongated workpieces, which is arranged in parallel with the production line, and is used to quickly complete the automatic loading or unloading of elongated workpieces 3 online, and place single or stacked elongated workpieces 3 separately Go to the working area, or stack the processed workpieces 3 together; the automatic feeding device includes a feeding table 5, a Y-axis moving device, a Z-axis moving device, a position sensing device, a material grabbing device 7, and a control system;

[0035] The loading workbench 5 includes a frame 4 and a worktable 1 which are connected to each other respectively, and one end of the worktable 1 is provided with a first positioning device 2, which includes a positioning block that limits the X-axis direction and the Y-axis direction, and the workpiece 3 placed in an orderly manner on the work surface 1, figure 1 , 2 The middle workpieces 3 are stacked, and the edge of the botto...

Embodiment 2

[0052] see Figure 1-10 , an automatic loading device for long strip workpieces, which is used to quickly complete the automatic unloading of long strip workpieces 3 online, and stack and place the processed workpieces 3 together;

[0053] The threaded aluminum profile that has been injected into the polyurethane foam strip 35, Figure 5 , 7 As shown, the processed workpieces 3 are stacked together. The process of stacking (unloading) is similar to the process of loading, except that the sequence of actions and the program are changed. This process should be clear from the above explanation. . Other compositions and connection relations are the same as in Embodiment 1.

[0054] The gears (gear A13, gear B) and rack (rack A14, rack B23) in the driving elements of the Z-axis moving device and the Y-axis moving device can adopt the belt pulley and the belt with the same function. Transmission replacement.

[0055] working principle

[0056] The automatic loading device for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com