Method for preparing aromatic compounds by conducting hydrogenation and depolymerization on spruce lignin through electro-catalysis technology

A technology of aromatic compounds and corn stalks, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of high production cost, high equipment requirements, harsh process, etc., achieve stable properties, high application value, and avoid complex processes conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

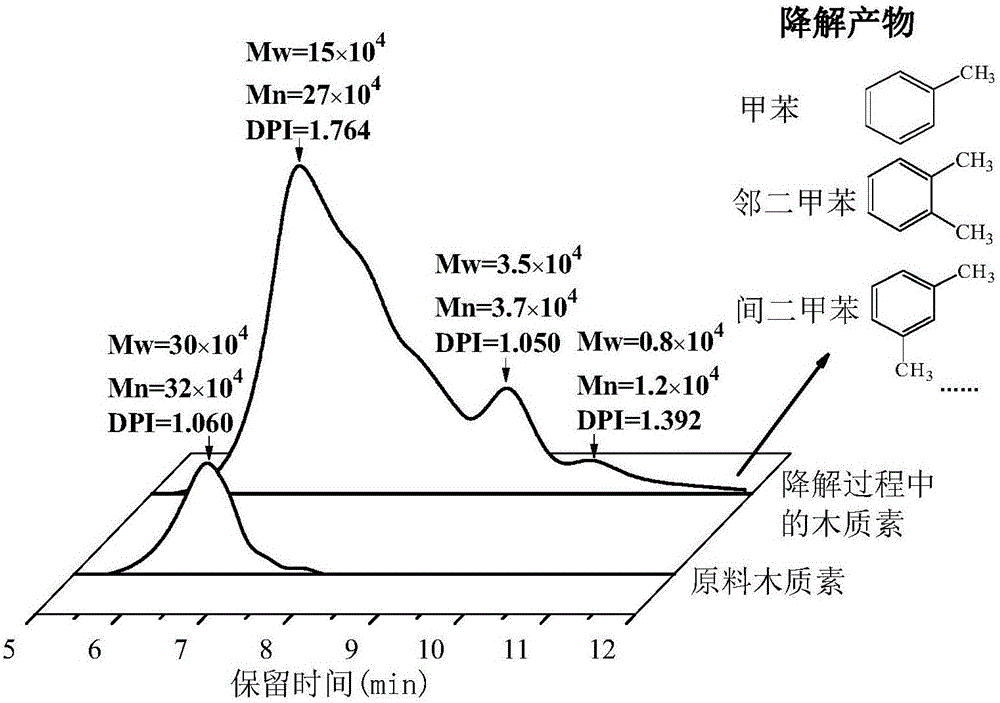

Method used

Image

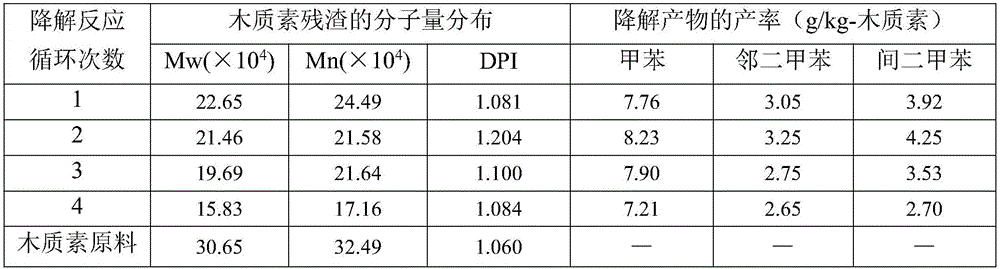

Examples

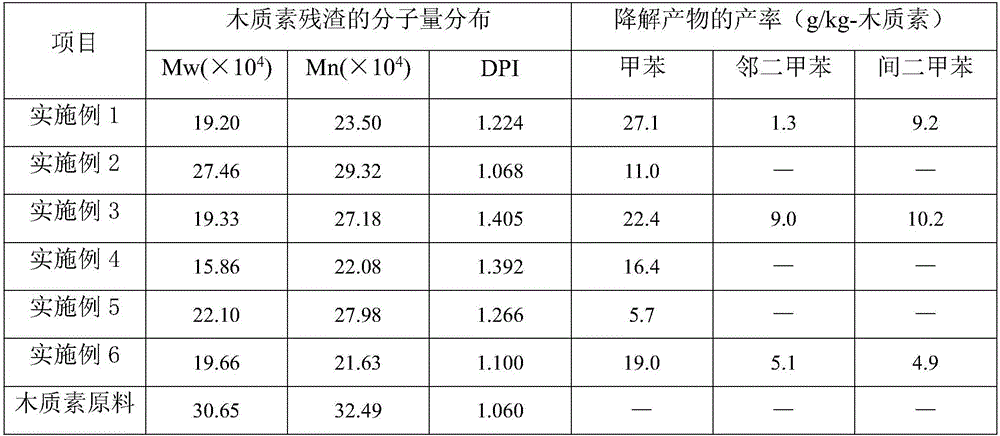

Embodiment 1

[0023] In a beaker equipped with a stirrer, add 8 g of corn stalk lignin and dissolve it in 200 mL of sodium hydroxide solution (1 mol / L) to form a homogeneous alkali solution of lignin, and put the beaker in a 30°C constant temperature water bath. The lignin alkali solution is electrolyzed under the DC stabilized power supply, and the anode is Pb / PbO 2 electrode, the cathode is a Ni electrode, and the current density is 30mA / cm 2 , the electrode working area is 24cm 2 . After 2 hours, the electrolysis was stopped to obtain a lignin degradation mother liquor. After adding 200mL chloroform to the degradation mother liquor, dilute sulfuric acid (0.86mol / L) was added dropwise while stirring to adjust the pH value of the solution to 1-2, the degradation products were extracted into the organic phase chloroform, and the remaining residue lignin was in the All precipitated from the mother liquor under acidic conditions. The residual lignin separated by filtration was washed with...

Embodiment 2

[0033] Dissolve 4g of corn stalk lignin in 200mL of sodium hydroxide solution (1mol / L), and apply a current density of 10mA / cm between the two electrodes 2 , Electrocatalytic degradation reaction time 4h. Other steps are with embodiment 1. The molecular weight distribution data of lignin residues and the yield of aromatics in degradation products are shown in Table 1.

Embodiment 3

[0035] Dissolve 2g of corn stalk lignin in 200mL of sodium hydroxide solution (0.6mol / L), and apply a current density of 20mA / cm between the two electrodes 2 , Electrocatalytic degradation reaction time 6h. Other steps are with embodiment 1. The molecular weight distribution data of lignin residues and the yield of aromatics in degradation products are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com