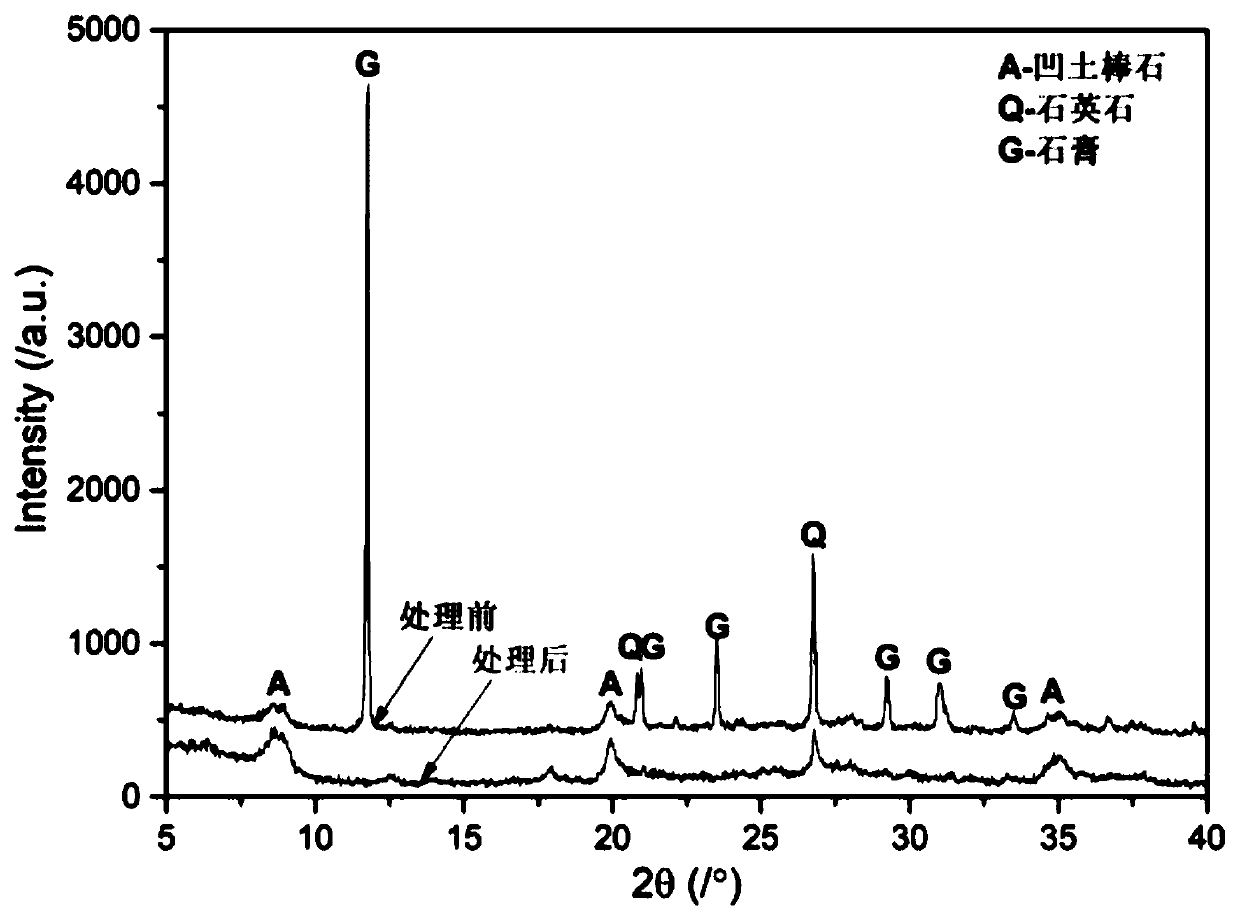

Purification and discoloration process of low-grade red attapulgite clay

A technology of attapulgite clay and attapulgite, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of unstable decolorization effect and easy "returning to yellow", so as to improve the decolorization effect and avoid The effect of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The low-grade (attapulgite content is less than 20%) red attapulgite clay raw ore soil is pulverized and passed through a 200-mesh sieve. The sieved raw ore soil powder is mixed with a sulfuric acid solution with a concentration of 0.5mol / l, the solid-to-liquid ratio is 1(g):10(ml), stirred ultrasonically for 1h, soaked and allowed to stand for 48h. Then through suction filtration and washing, the pretreated slurry is obtained. Then add sodium hexametaphosphate, sodium oxalate and sodium sulfide, its consumption is respectively 7%, 10% and 1% of the attapulgite clay quality, ball milling (ball material mass ratio is 1:2, rotating speed is 500r / min) 0.5h. Take it out and let it stand, decant the solution to obtain the upper layer attapulgite suspension, centrifuge, wash, dry, and pulverize to obtain high-purity off-white attapulgite.

Embodiment 2

[0029] The low-grade (attapulgite content is less than 20%) red attapulgite clay raw ore soil is pulverized and passed through a 200-mesh sieve. The sieved raw ore soil powder is mixed with hydrochloric acid solution with a concentration of 0.5mol / l, the solid-to-liquid ratio is 1(g):30(ml), stirred ultrasonically for 1h, soaked and allowed to stand for 24h. Then through suction filtration and washing, the pretreated slurry is obtained. Then add sodium hexametaphosphate, sodium oxalate and sulfide, its consumption is respectively 3%, 15% and 5% of the attapulgite clay quality, ball milling (mass ratio of ball to material is 1:1, rotating speed is 200r / min) 1h. Take it out and let it stand, decant the solution to obtain the upper layer attapulgite suspension, centrifuge, wash, dry, and pulverize to obtain high-purity off-white attapulgite.

Embodiment 3

[0031] The low-grade (attapulgite content is less than 20%) red attapulgite clay raw ore soil is pulverized and passed through a 200-mesh sieve. The sieved raw ore soil powder is mixed with a phosphoric acid solution with a concentration of 0.5mol / l, the solid-to-liquid ratio is 1(g):20(ml), stirred ultrasonically for 1.5h, soaked and allowed to stand for 24h. Then through suction filtration and washing, the pretreated slurry is obtained. Then add sodium hexametaphosphate, sodium oxalate and ferrous sulfide, its consumption is respectively 4.5%, 20% and 2.5% of the attapulgite clay quality, ball milling (ball material mass ratio is 1:3, and the rotating speed is 300r / min ) 1.5h. Take it out and let it stand, decant the solution to obtain the upper layer attapulgite suspension, centrifuge, wash, dry, and pulverize to obtain high-purity off-white attapulgite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com