Self-cleaning roll clearer for intelligent combing machine

A comber, self-cleaning technology, applied in the direction of comber, textile and papermaking, fiber processing, etc., can solve the problems of unfavorable combing quality, short cleaning cycle, influence, etc., achieve excellent cleaning effect, convenient and efficient use, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

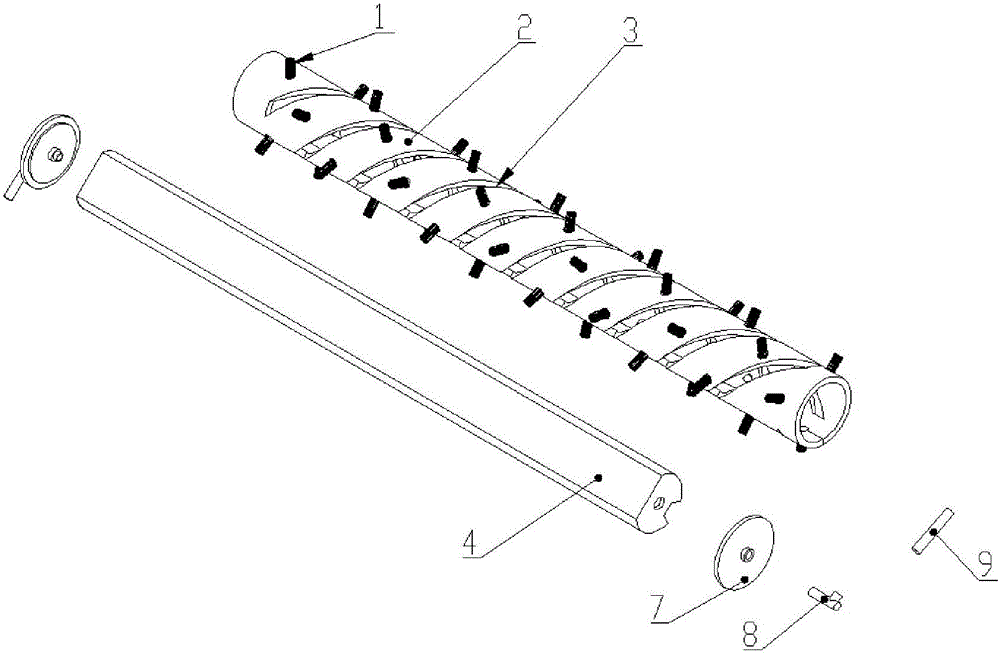

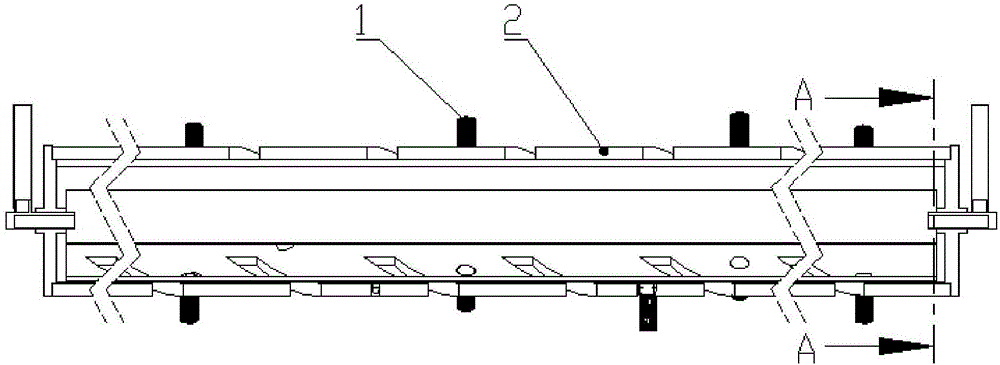

[0023] Embodiment: a kind of self-cleaning cashmere stick of intelligent combing machine, comprises cashmere roll shell 2, bunch of brown silk 1, cashmere roll shell 4, air hole part 8 and trachea 9, and described cashmere roll shell 4 is fixedly inserted In the cashmere shell 2, a sealed space is formed between the outer side of the cashmere shell 4 and the inner side of the cashmere shell 2, and the surface of the cashmere shell 2 is fixedly provided with a number of bunches of brown silk 1 protruding from the surface of the cashmere shell 2, and the cashmere roll Shell 2 surface is also provided with the suction hole 3 that is communicated with its internal sealing space, and air pipe 9 is communicated with the sealing space in the cashmere shell shell by air hole part 8, forms negative pressure in the air pipe 9 (trachea 9 can be connected with comber air channel connected).

[0024] The self-cleaning velvet stick 11 of the intelligent comber is installed in the groove on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com