Unit assembly type water-filled rubber anti-flood wall and assembly method thereof

A prefabricated, flood control wall technology, applied in dikes, dams, coastline protection, etc., can solve the problems of needing concrete, large one-time investment, and limited objective conditions for promotion, and achieve the best flood control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

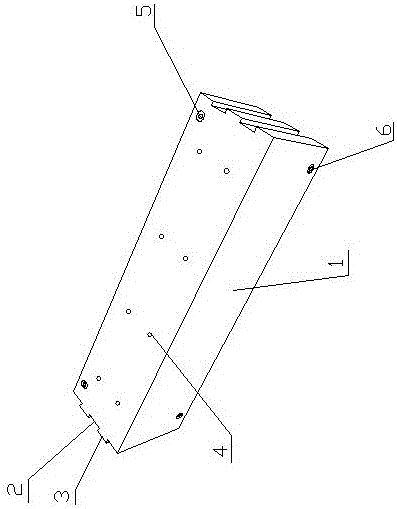

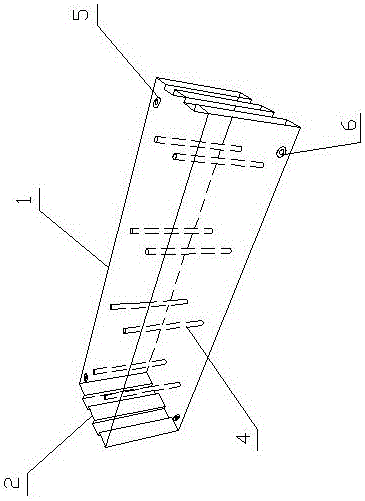

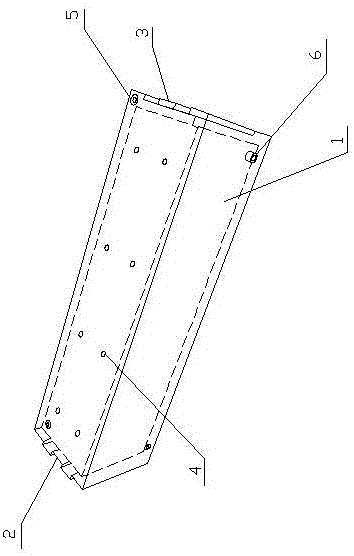

[0025] A unit-assembled rubber water-filled flood wall, which consists of: a water-filled rubber unit 1, one end of the water-filled rubber unit is provided with a combined structure of a dovetail groove 2 and two mortise and tenon joints 3, and the water-filled rubber unit The other end of the water-filled rubber unit is provided with two dovetail grooves and three mortise-and-mortise joint structures, and the upper end of the water-filled rubber unit is evenly provided with a group of cylindrical holes 4 with the same aperture and depth. Two water inlets 5 with the same aperture are provided at both ends of the upper surface of the water-filled rubber unit, and two outlets with the same aperture are provided on both sides of the lower end of the side of the long side of the water-filled rubber unit. Nozzle 6.

Embodiment 2

[0027] According to the unit-assembled rubber water-filled flood wall described in Embodiment 1, a group of said water-filled rubber units form a flood wall through the splicing combination of said dovetail groove and said mortise and tenon.

Embodiment 3

[0029] According to the unit-assembled rubber water-filled flood protection wall described in Embodiment 1 or 2, according to the height of the water level, the height of the water-filled rubber units can be increased and arranged in an upward dislocation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com