Ground cement laying equipment for construction site

A construction site and ground technology, applied in the direction of construction, building structure, etc., can solve the problems of difficult paving, time-consuming and laborious, difficult cementing, etc., to avoid time-consuming and laborious, save time, and quickly pave the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

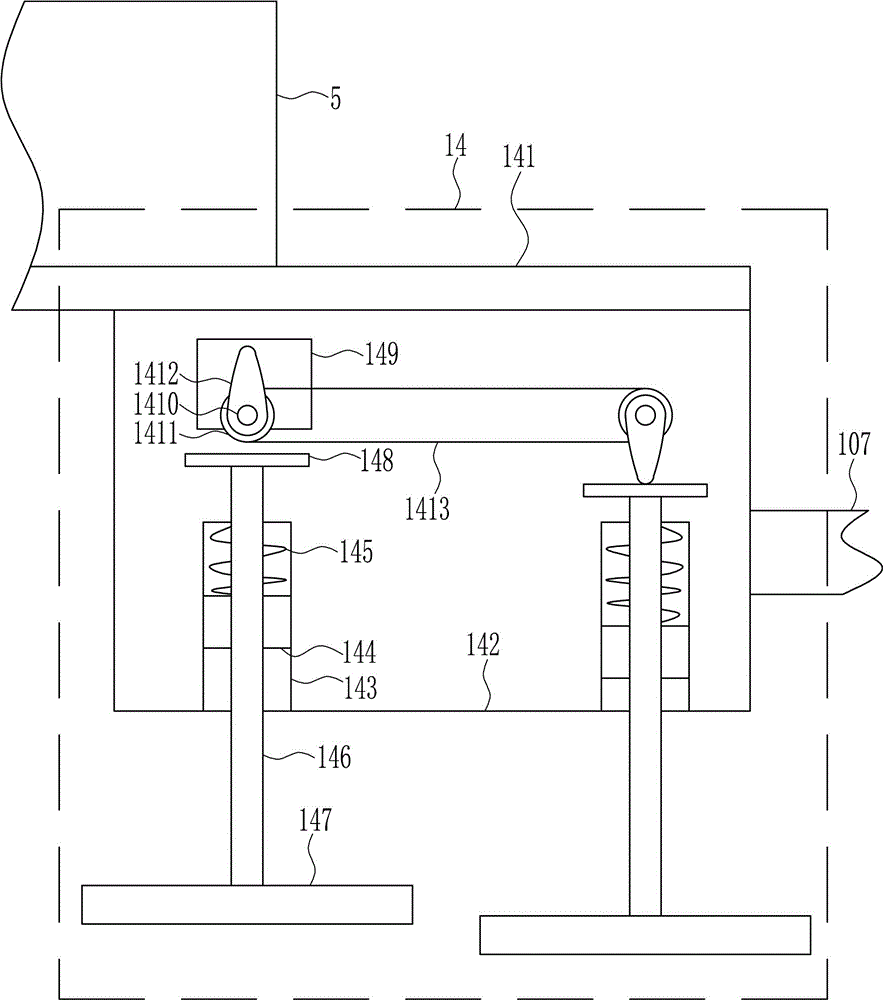

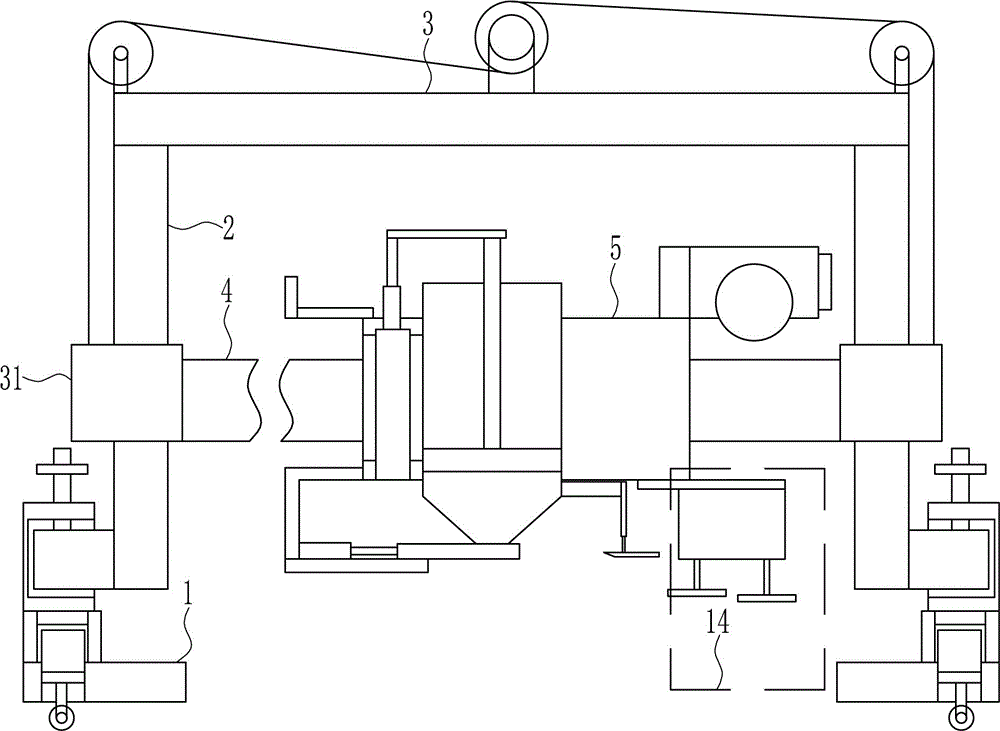

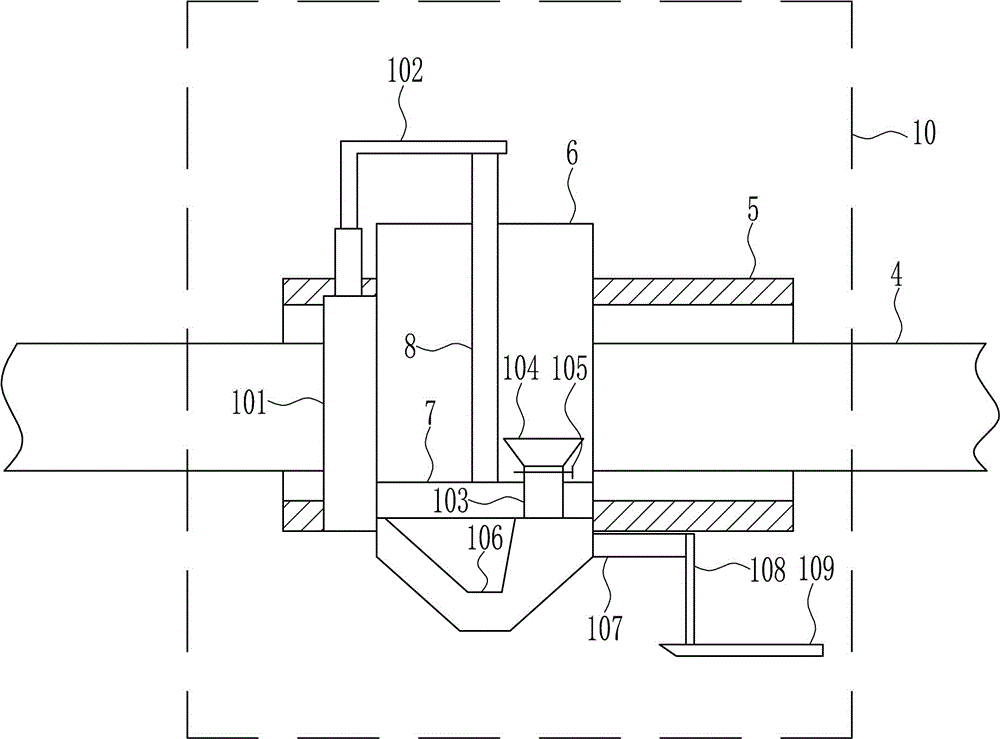

[0034] A kind of ground cement laying equipment for construction site, such as Figure 1-14 As shown, it includes a base plate 1, a first guide rail 2, a first slide rail 21, a first slider 22, a first leg 23, a wheel 24, an insertion rod 27, a top plate 3, a first guide sleeve 31, and a first screw rod 33. , the first pressing block 34, the second leg 35, the fixed pulley 36, the third leg 37, the electric reel 38, the pull wire 39, the second guide rail 4, the second guide sleeve 5, the material box 6, the rubber block 7 and push Rod 8, the first guide rail 2 is installed on the bottom plate 1 by welding, the top plate 3 is installed on the upper end of the first guide rail 2 by welding, the first slide rail 21 is installed in the bottom plate 1 by bolt connection, the first slide The first slider 22 is slidably connected to the rail 21, the first leg 23 is installed on the lower side of the first slider 22 by welding, the lower end of the first leg 23 is rotatably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com