An electronic detonator-based blasting method for ultra-deep and large-section vertical shafts

An electronic detonator and cross-section technology, applied in blasting, shaft equipment, sinking, etc., can solve the problems of large shaft drilling rig machinery, large auxiliary workload, low safety and reliability, etc., and achieve good stability of the shaft wall and fast filling time , the effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

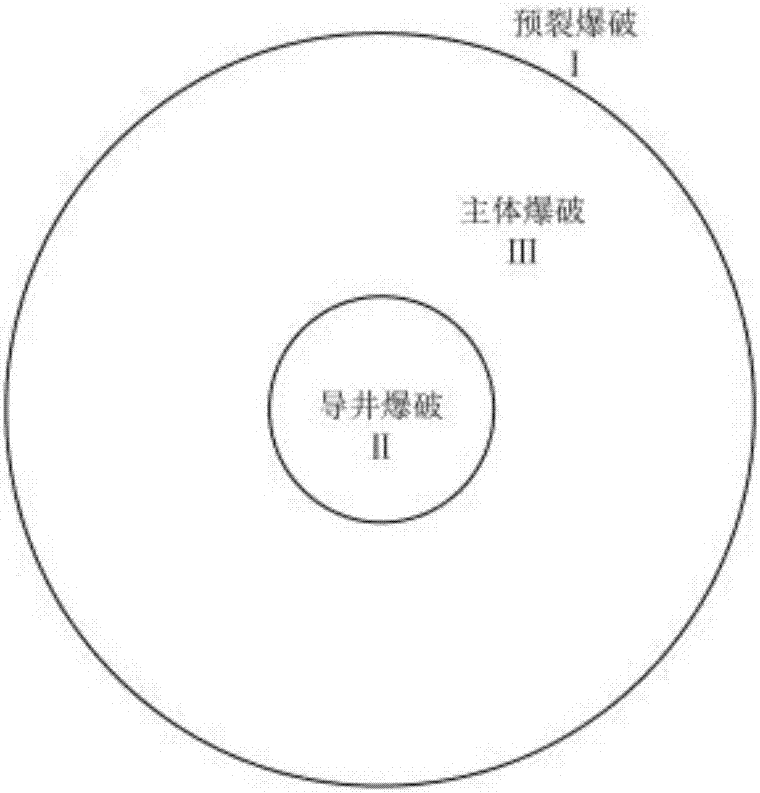

[0051] A method for blasting an ultra-deep large-section vertical shaft at one time based on an electronic detonator, comprising the following steps:

[0052] (1) First, according to the size of the section, the expansion coefficient of the rock and the size of the compensation space at the bottom, determine the maximum amount of blasting each time;

[0053] The principle of determining the maximum blasting volume per time is that the maximum blasting volume multiplied by the rock expansion coefficient is less than or equal to the sum of the original rock volume and the bottom compensation space; after each blasting, the blasting ballast is immediately removed to create more compensation space, To increase the amount of blasting next time.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com