Energy-saving high-efficiency garbage processing system

A garbage disposal system and garbage disposal technology are applied in the field of energy-saving and efficient garbage disposal systems, which can solve the problems of consuming sanitation workers and less information about the quantity, so as to increase the number of garbage collections, reduce the collection frequency, human resources and vehicle resources Configure the most optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described in conjunction with the following examples.

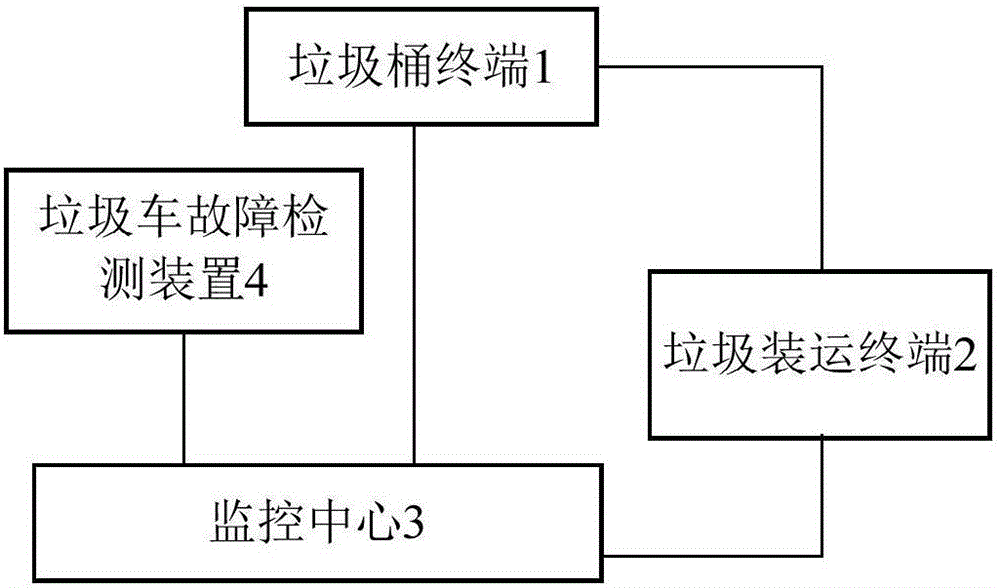

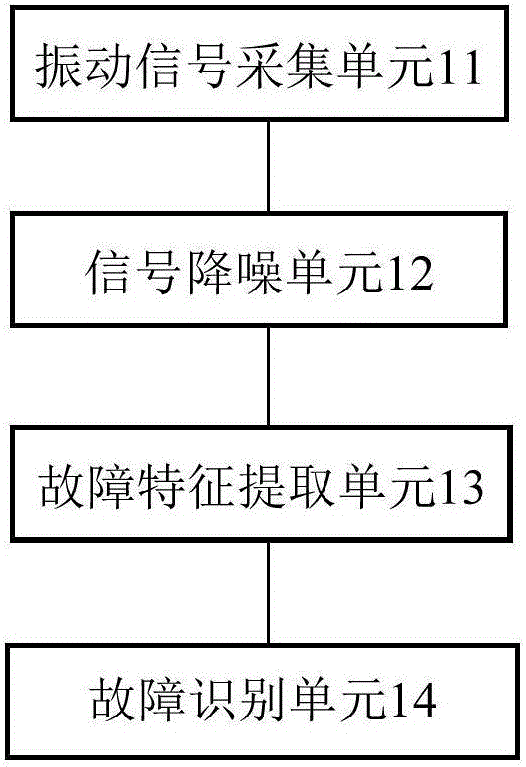

[0013] see figure 1 , figure 2 , an energy-saving and high-efficiency garbage disposal system of the present embodiment, comprising a garbage can terminal 1, a garbage disposal terminal 2, a garbage truck fault detection device 4 and a monitoring center 3, and the monitoring center 3 is connected with the garbage truck fault detection device 4, the garbage truck fault detection device The bin terminal 1 and the garbage disposal terminal 2 are connected by wireless communication; the garbage bin terminal 1 is used to monitor the amount of garbage in the garbage bin, and when the amount of garbage reaches or exceeds a preset value, it sends a full signal and position to the monitoring center 3 Compressed data of information; the monitoring center 3 processes the compressed data, generates garbage shipment operation information and location information, and selects a garbage truck mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com