Operating mechanism and switching apparatus using same

A technology of operating mechanism and switchgear, applied in the field of operating mechanism and switchgear, can solve the problems of unfavorable production and maintenance, complex adjustment process, limited adjustment range, etc., so as to reduce short-term output power and transient torque Output capability, small size and weight, and low moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

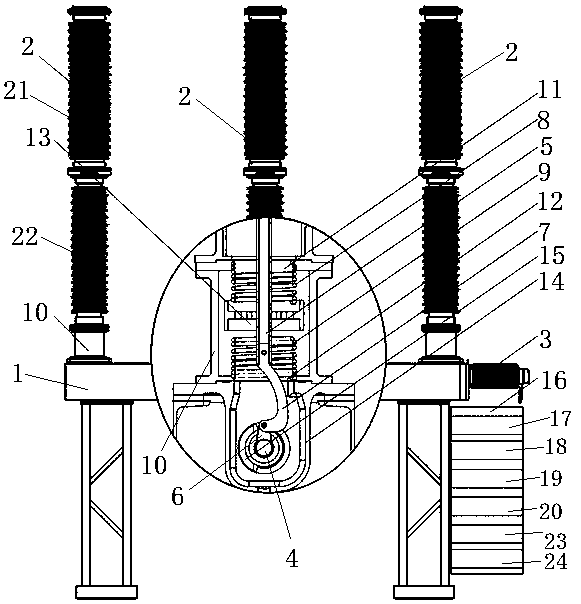

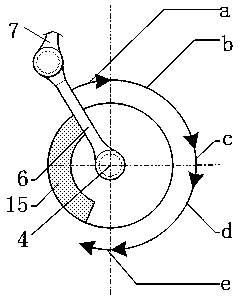

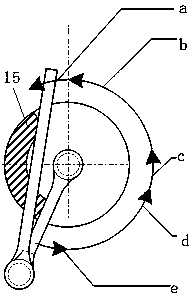

[0026] A specific embodiment of a switch device of the present invention, such as Figure 1 to Figure 3 As shown, the switchgear includes a bracket 1, a three-phase single-pole circuit breaker 2 installed on the bracket 1, and an operating mechanism for driving the three-phase single-pole circuit breaker 2 to open and close synchronously. The three-phase single-pole circuit breakers 2 have the same structure, and each phase circuit breaker includes an arc extinguishing chamber 21 and an insulating support 22 . The operating mechanism includes a servo motor 3, which constitutes the power device of the operating mechanism. The servo motor 3 is connected to the moving contact of the circuit breaker through the transmission mechanism, and then drives the moving contact of the circuit breaker to move up and down to realize opening and closing. The transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com