Mechanical-sealing type submersible motor

A technology of mechanical seals and submersible motors, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor sealing effect and affecting the service life of bearings, and achieve the effect of prolonging service life and preventing water from entering the bearing chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

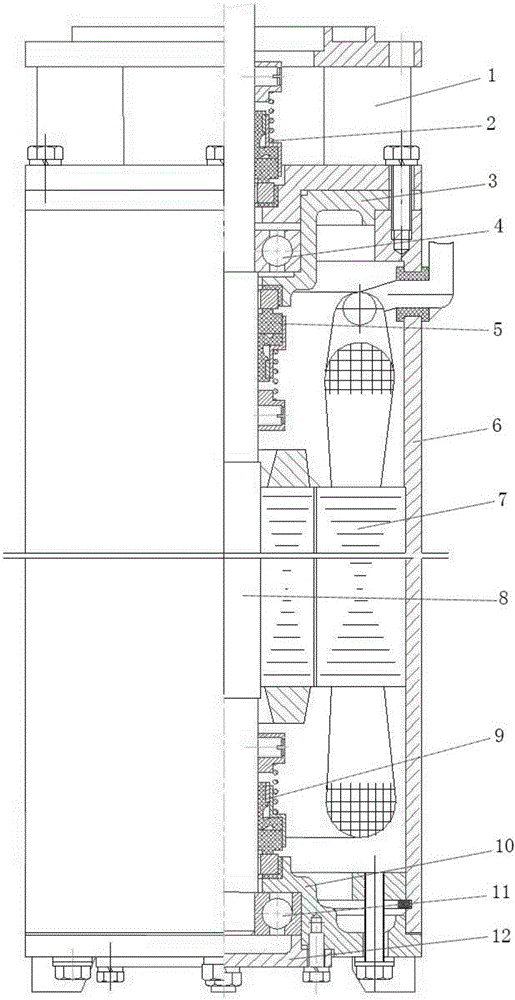

[0018] The structure of the lower part of the lower bearing 11 remains unchanged. It is a kind of static seal, which is connected to the lower bearing housing 10 by the bearing cover 12 and the sealing ring to form a reliable seal for the lower part of the lower bearing 11, and water cannot enter the bearing chamber from this part. A mechanical seal, which is the third mechanical seal 9 , is arranged on the upper part of the lower bearing seat 10 . Specific implementation methods: a. Set the static ring seat (chamber) of the third mechanical seal 9 on the upper part of the lower bearing seat 10; b. The matching part between the lower part of the rotor assembly 8 and the third mechanical seal 9 is made according to the requirements of the mechanical seal Corresponding shaft diameter, steps or positioning holes, etc.; c. Install the third mechanical seal 9 to form a dynamic seal on the upper part of the lower bearing 11 to prevent water from entering the lower bearing chamber at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com