cast aluminum wheels

A wheel, cast aluminum technology, applied in the direction of wheels, wheel manufacturing, spoked wheels, etc., can solve the problems of reduced shape and rigidity, reduced spoke quality, reduced cast aluminum wheels, etc., to reduce mass, increase mass, and improve stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

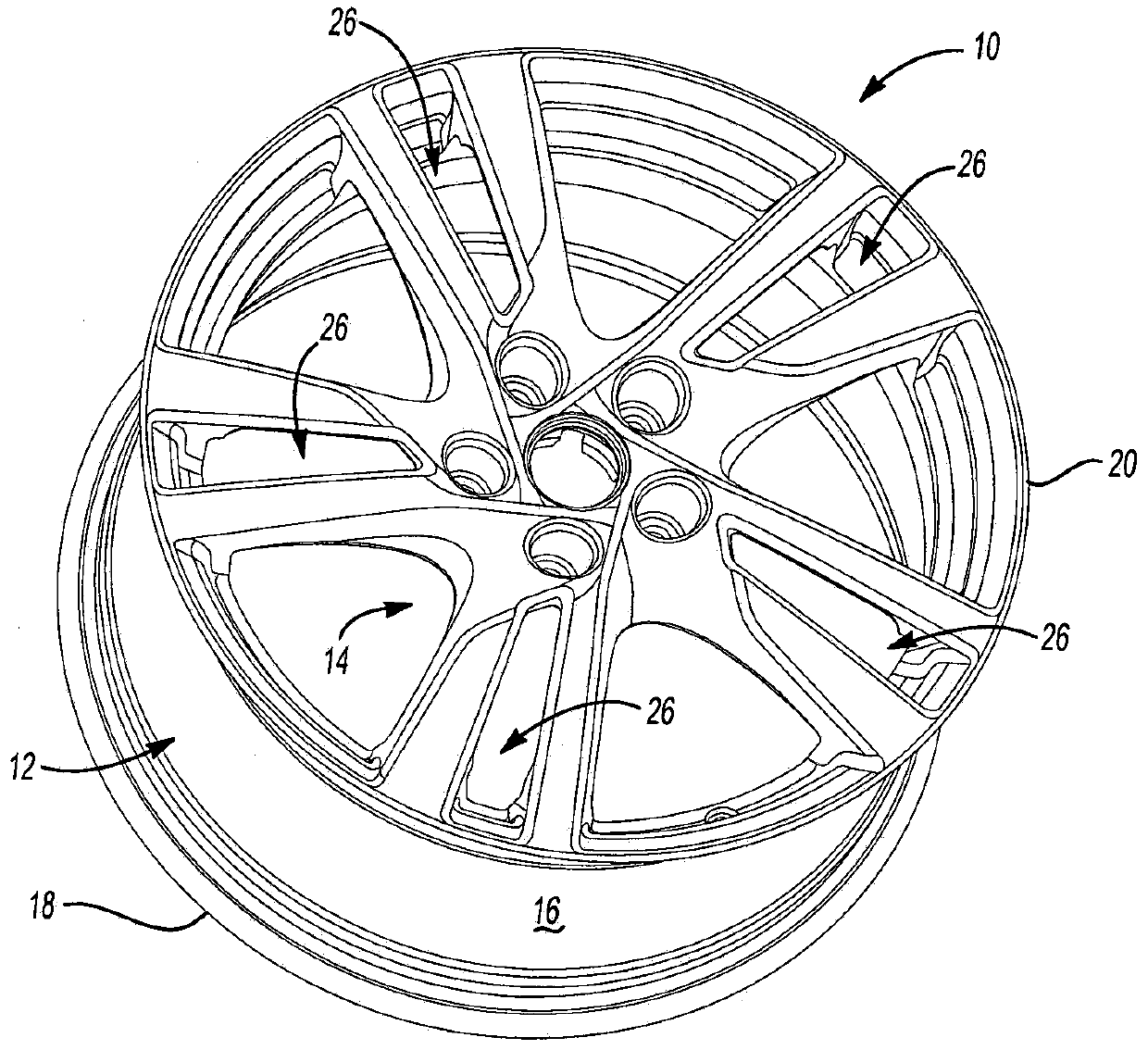

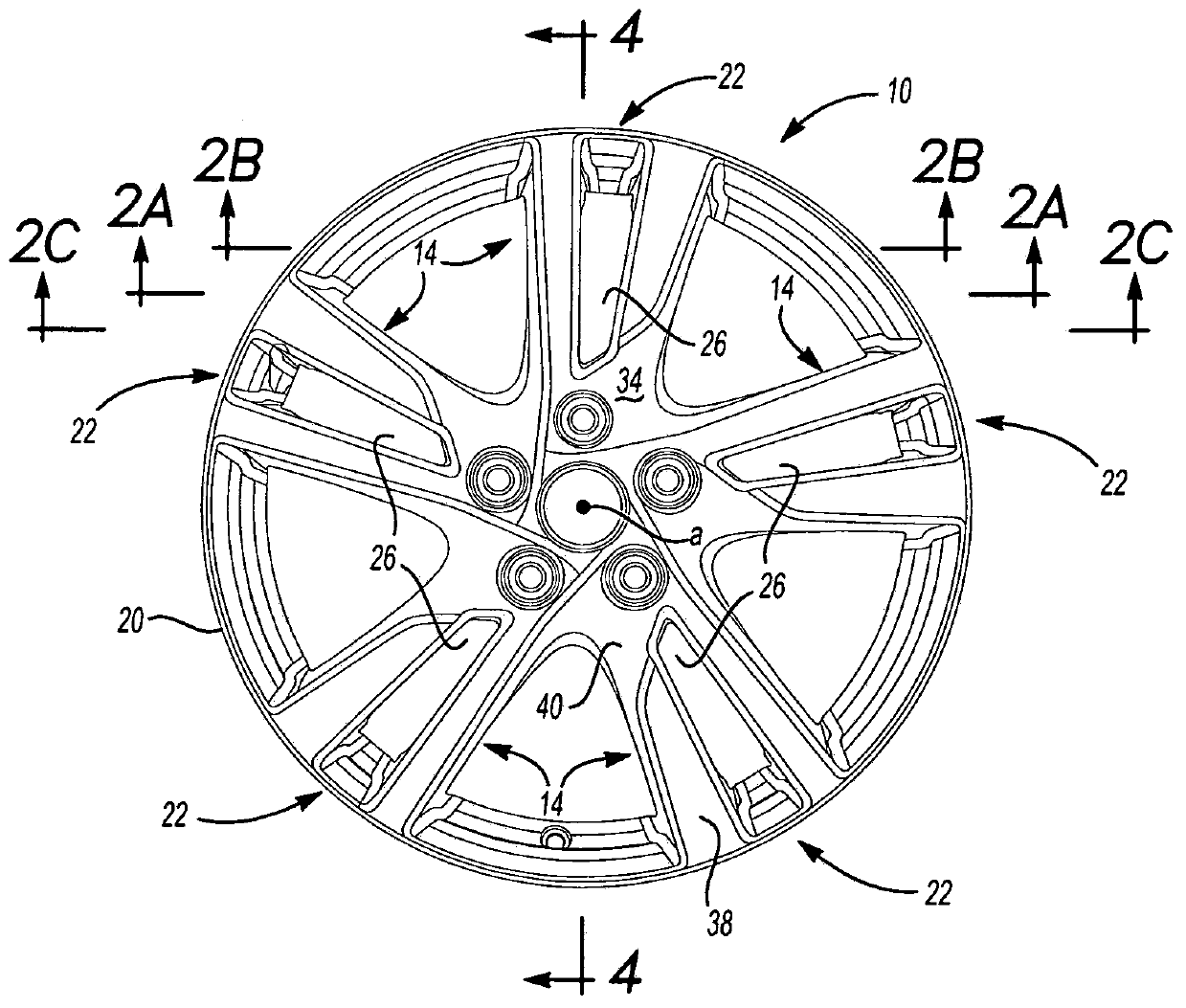

[0029] refer to figure 1 , the wheel of the invention is generally indicated with reference numeral 10 . The wheel comprises a rim element 12 ( figure 2 ). The central element 14 extends radially outwards between the axis a and the rim element 12. The rim member 12 defines a sunken surface (or annular wall) 16 at a position disposed radially inward from the distal rim 18 and the proximal rim 20, between the distal rim 18 and the proximal rim. Between the rims 20 extend. Those of ordinary skill in the art will appreciate that the proximal rim 18 is located on the outside of a motor vehicle (not shown) and the distal rim 20 is located on the inside of the motor vehicle. Furthermore, the sunken surface 16 is defined in a known manner as a cylindrical surface about the axis a.

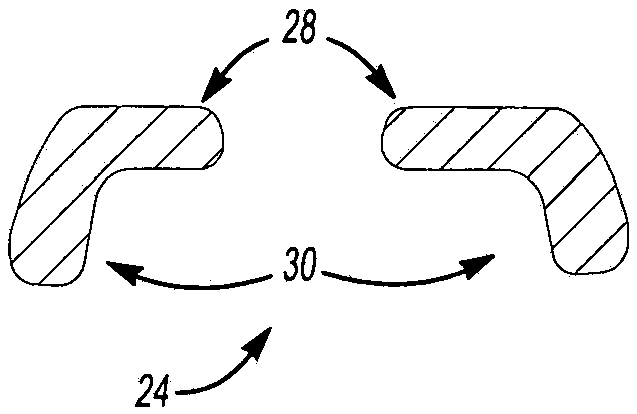

[0030] now refer to figure 2 , Figure 2A-Figure 2C , the central element 14 includes a plurality of cooperable spoke pairs 22 . In this embodiment, each spoke pair 22 defines opposed, generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com