Casting slag drawing, dust removing and heat insulation device

A technology of heat insulation device and dust hood, which is applied in the direction of removing smoke and dust, foundry equipment, manufacturing tools, etc., can solve the problems of high labor intensity, high slag temperature, and difficulty in dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the examples.

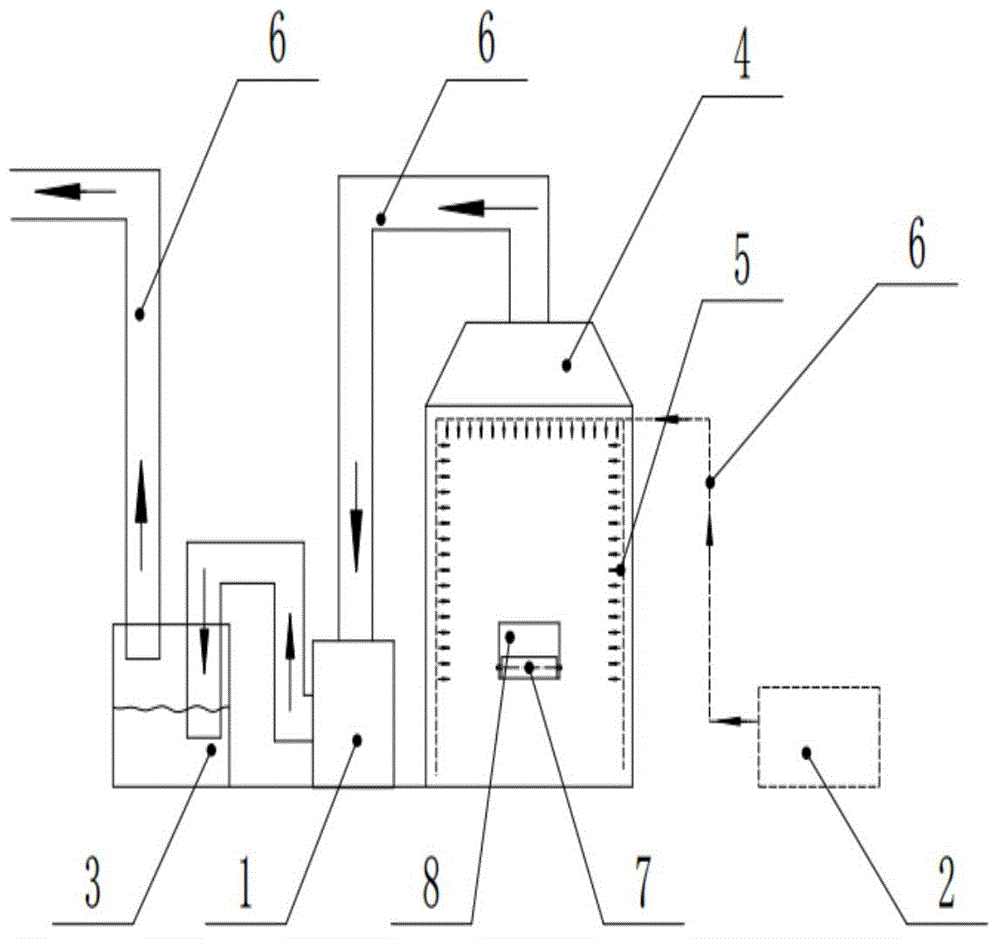

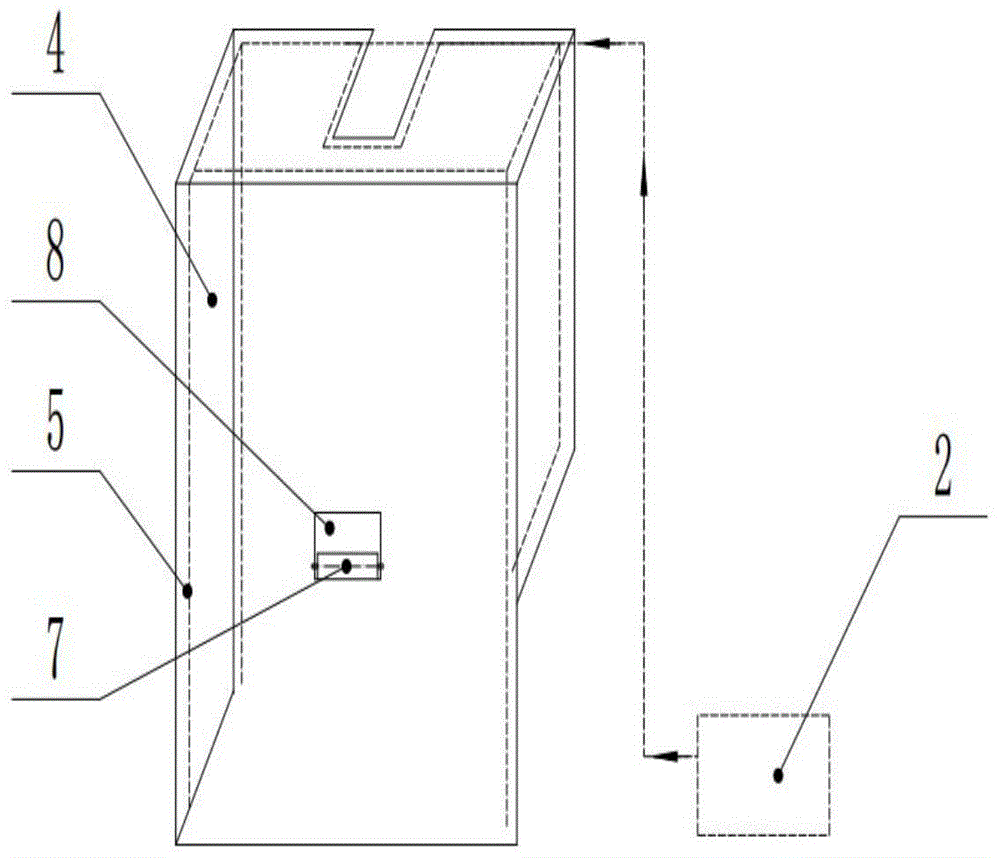

[0013] Such as figure 1 and figure 2 As shown, the present invention is provided with a blower 2, a slag removal device, an exhaust fan 1, and a water filter tank 3 in sequence, and every two adjacent devices are connected by a pipeline 6.

[0014] The slag removal device is provided with a dust removal cover 4, and an inner and outer isolation curtain wall 5 is provided near the inner wall of the dust removal cover 4, and the pipeline 6 between the slag removal device and the blower 2 directly leads into the inner and outer isolation curtain walls 5. An isolation window 8 is provided in the lower part of the front of the dust cover 4 to achieve the purpose of heat insulation; the lower edge of the isolation window 8 is provided with a slag removal drive wheel 7, which can realize the sliding of the slag removal drive wheel 7 during slag removal , thereby reducing the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com