A cabin entry auxiliary tool for a power all-in-one machine

A technology of auxiliary tools and all-in-one machines, applied in manufacturing tools, hand-held tools, etc., can solve problems such as bumping of power all-in-one machines, large errors of power all-in-one machines, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The best embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

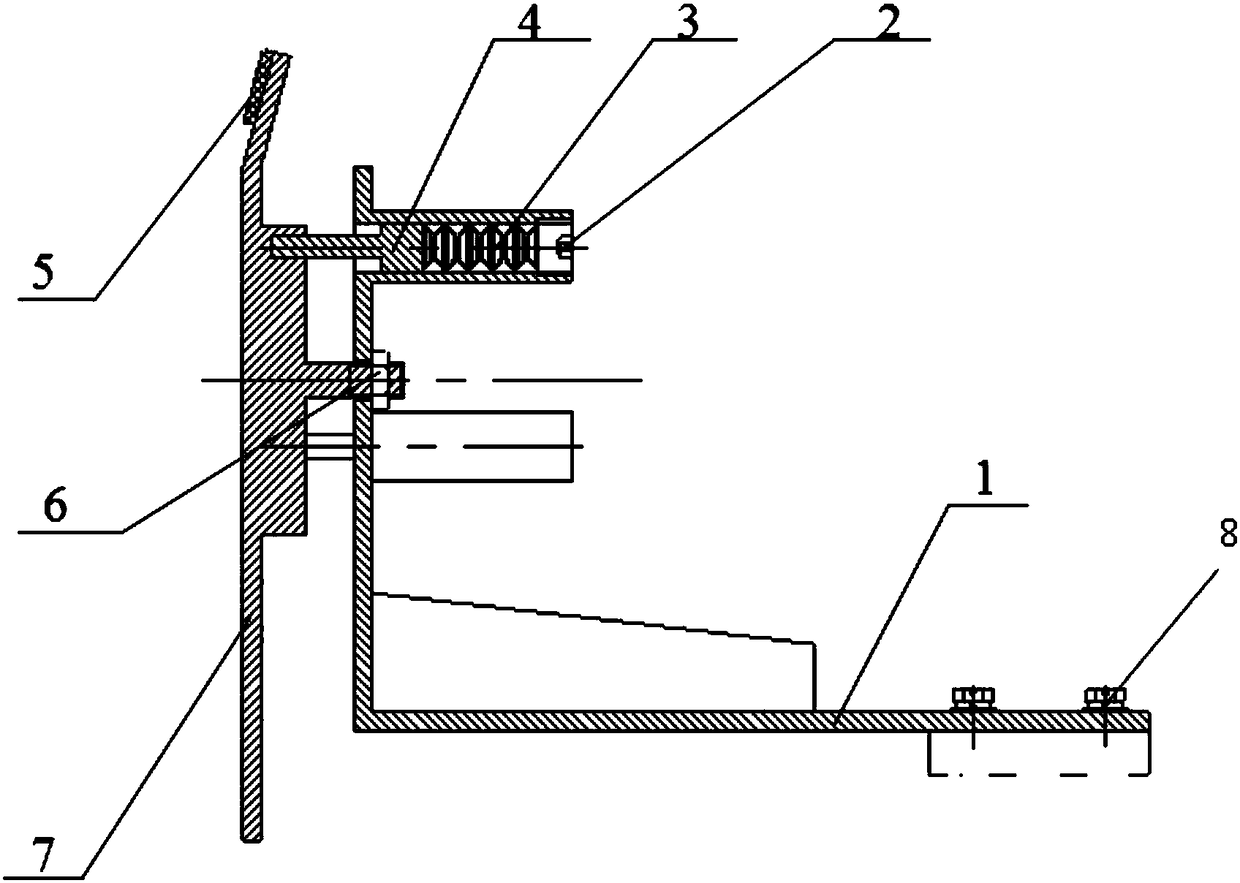

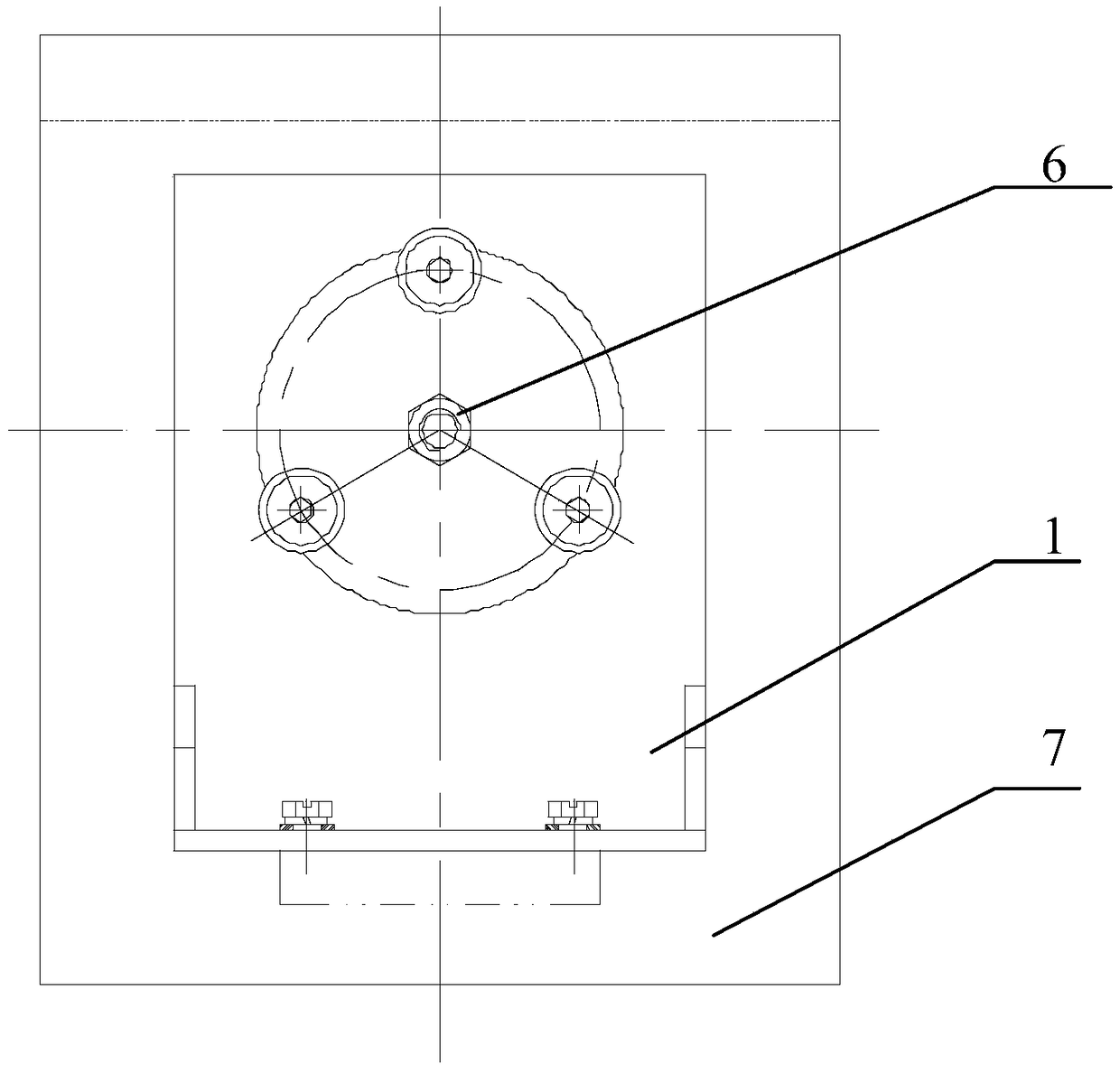

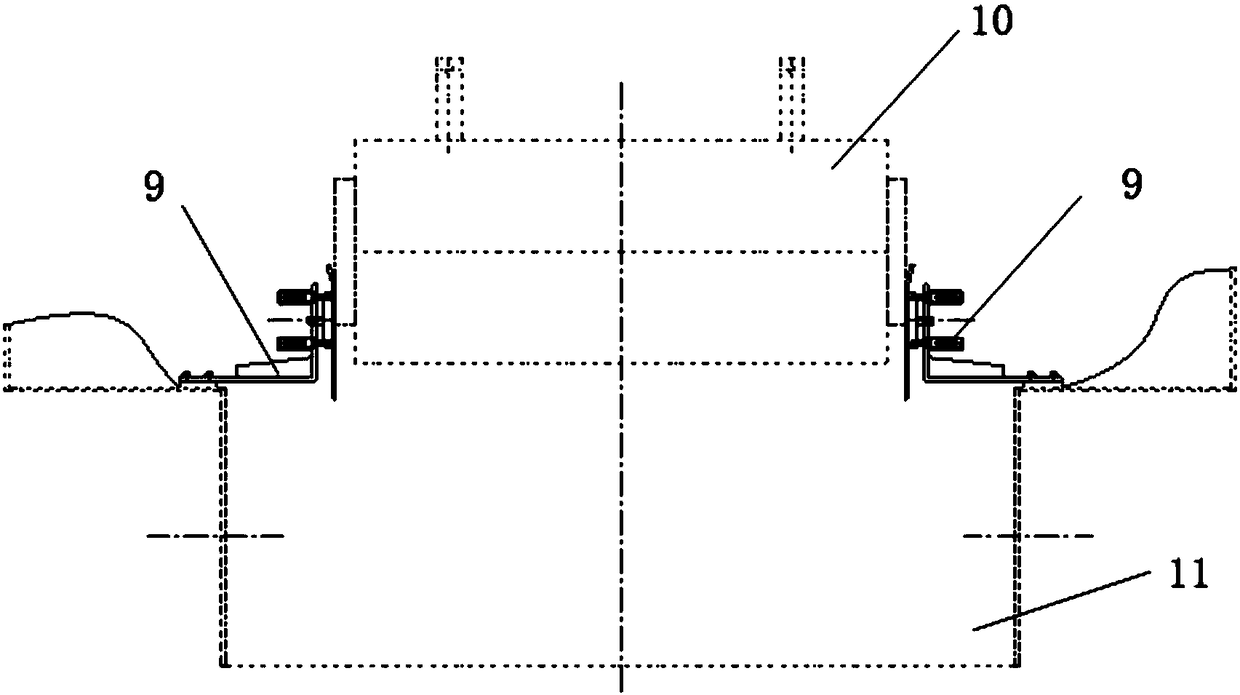

[0017] Such as figure 1 , figure 2 As shown, an auxiliary tool for entering a cabin for a power integrated machine of the present invention includes a base body 1, a limiting screw plug 2, a compression spring 3, a positioning pin 4, a buffer rubber block 5, a fine adjustment nut 6, and a guide plate 7.

[0018] Among them, the base 1 is L-shaped, the L-shaped vertical plate has a central hole (where the optical axis of the guide plate 7 is installed), and three pin barrels uniformly distributed in the circumferential direction; the pin barrel is sequentially installed with positioning pins 4 and compression springs 3 , Limit screw plug 2; L-shaped horizontal plate is fixed to the car body.

[0019] The center of the guide plate 7 has an optical axis with a threaded end, and three blind holes for placing the positioning pins 4. The position of the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com