Graphite heat dissipation film finished product collecting device

A technology for collecting devices and film products, which is applied in the direction of stacking receiving devices, transportation and packaging, and sending objects, which can solve the problems of high labor intensity and poor continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

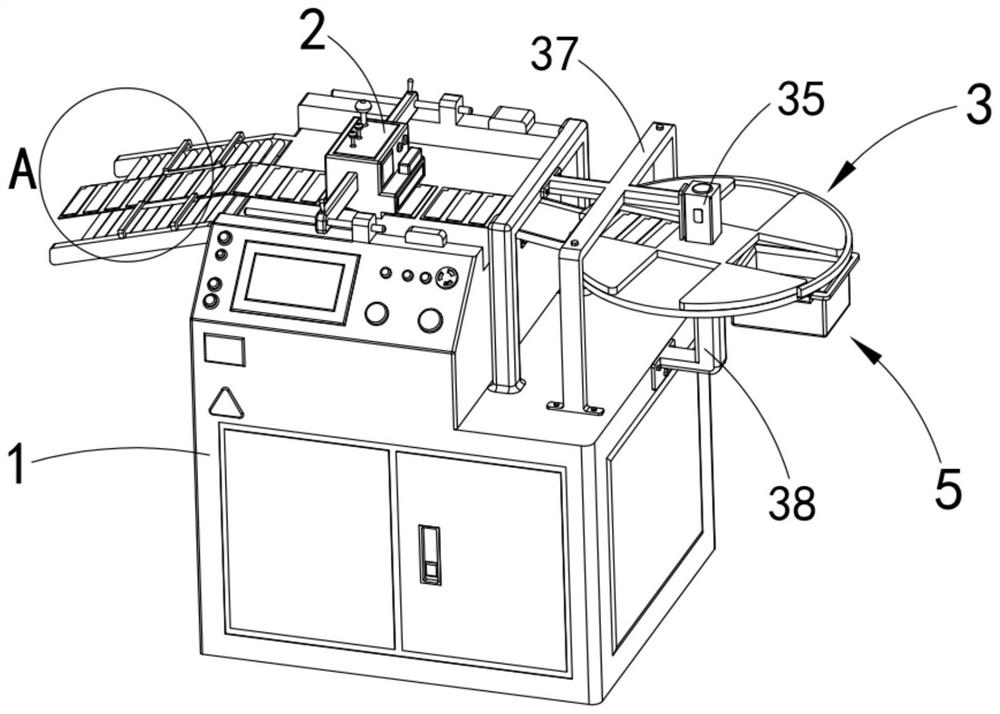

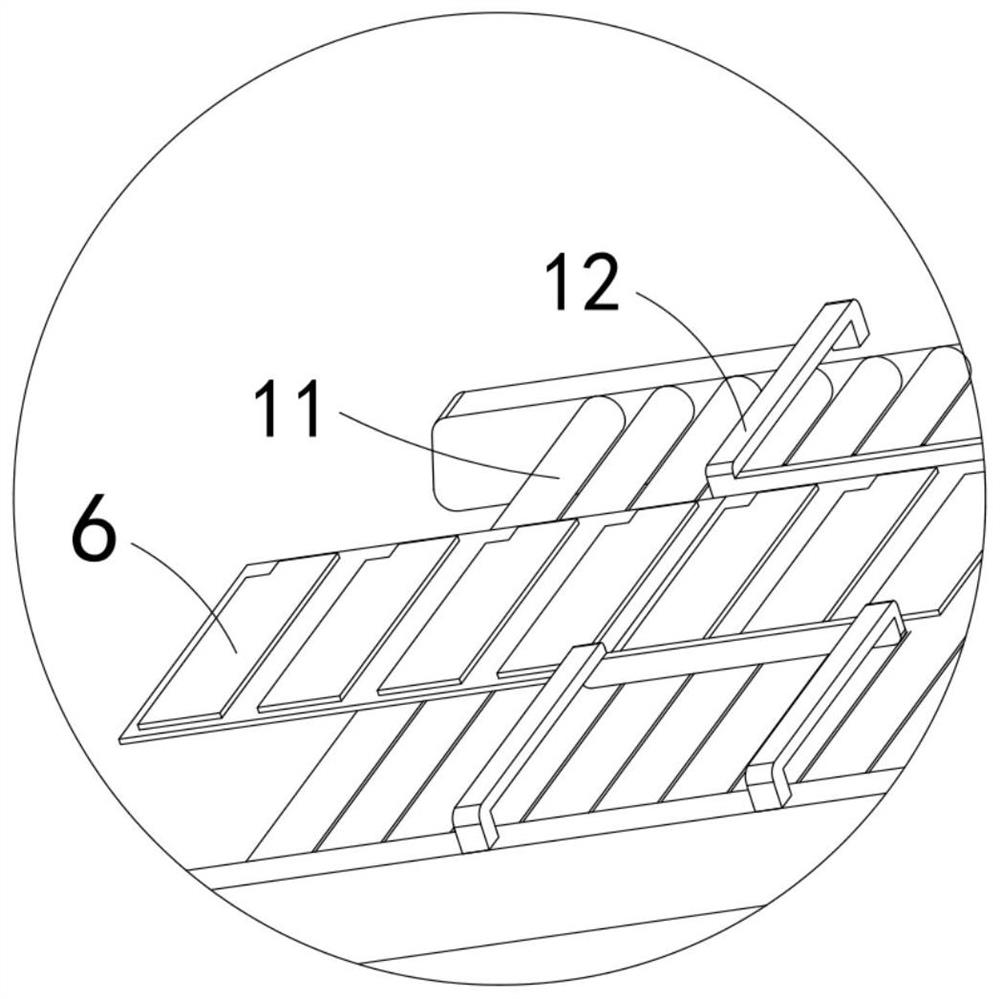

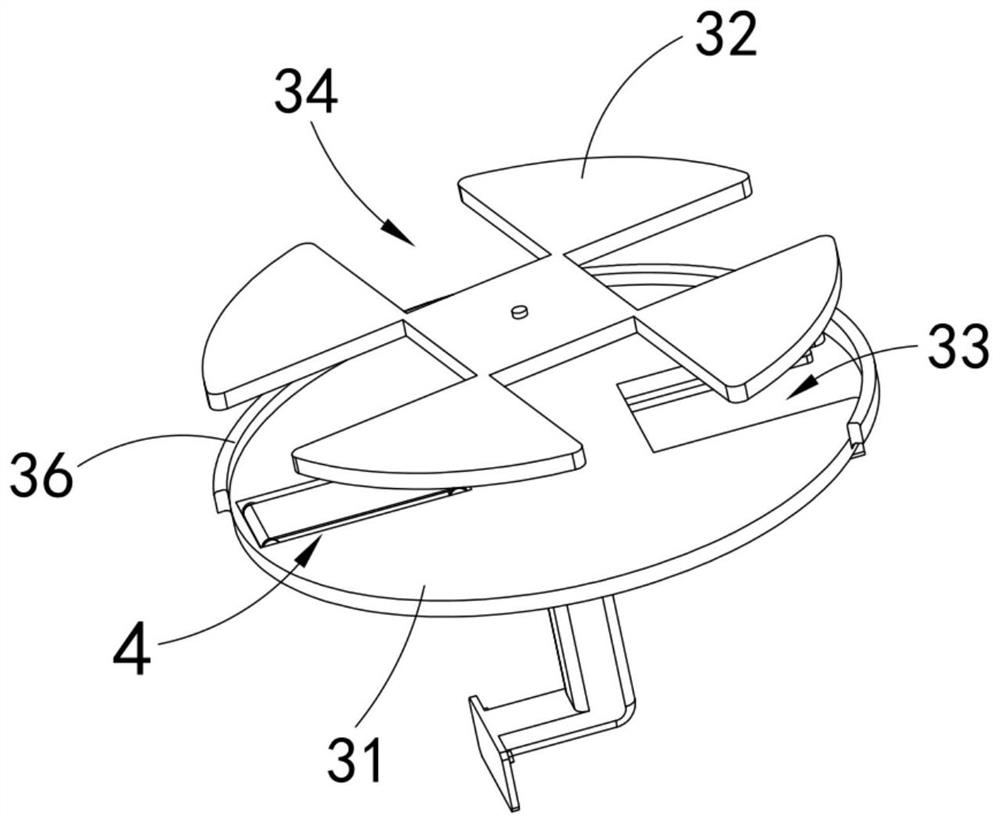

[0028] like Figure 1 to Figure 6 As shown, a graphite cooling film finished product collection device includes a support table 1, a cutting machine 2 is arranged on the support table 1, and a transfer assembly 3 is provided at the end of the support table 1, and the transfer assembly 3 includes a fixed plate 31 and the rotating disk 32 that is arranged on the fixed disk 31, the fixed disk 31 is provided with a blanking port 33, and the rotating disk 32 is provided with a number of receiving grooves 34 in the circumferential dire...

Embodiment 2

[0037] like Figure 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that the storage assembly 5 includes a set of chute 51 fixedly arranged on the bottom surface of the fixed plate 31 , a limiting block 52 and a collection box 53 slidably arranged in the chute 51 .

[0038]Here, in this embodiment, the collection box 53 can slide in the chute 51, which is convenient for placing the collection box 53 to pick up the heat dissipation film 6 falling from the discharge port 33, and it is convenient to pull the collection box 53 away after the storage is completed. , the limit block 52 makes the opening of the collection box 53 always remain in the middle position below the discharge opening 33 during each inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com