A track sliding arc extinguishing device

An arc extinguishing device, sliding technology, applied in the direction of electrical components, insulators, circuits, etc., can solve the problems of increasing the structural complexity of the arc extinguishing device, the limited number of arc extinguishing gas pills, and increasing maintenance costs, etc., to achieve simple structure, increase Effect of gravity and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

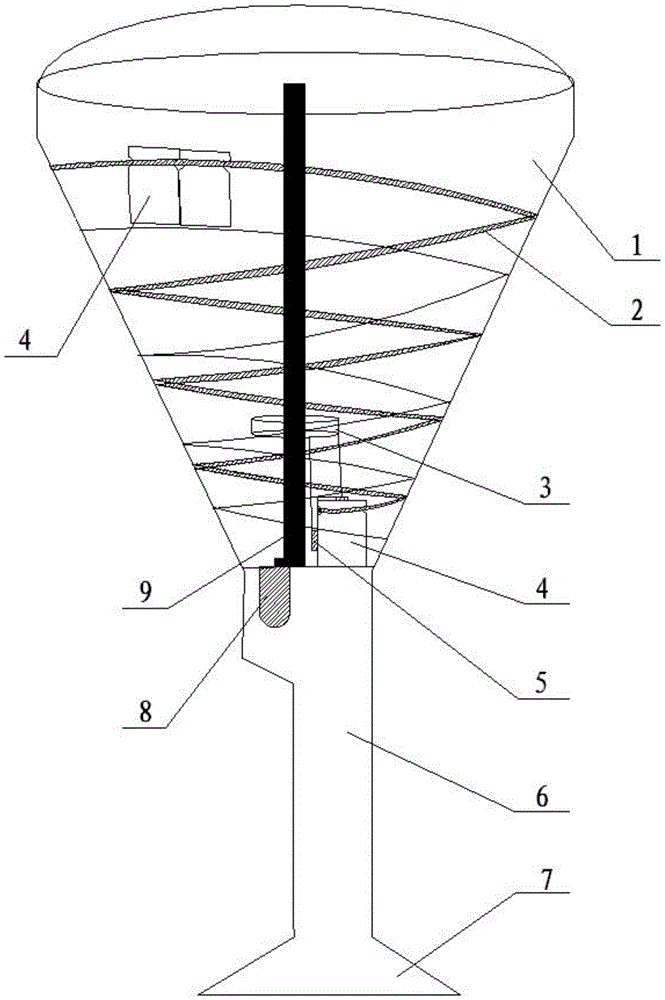

[0029] Such as figure 1 As shown, a rail-sliding arc extinguishing device includes a magazine storage bin 1 and an arc extinguishing cylinder 6; inside the magazine storage bin 1, a trigger coil 3 and an arc-guiding fitting 9 passing through the trigger coil 3 are arranged, and the storage The bottom of the magazine 1 is provided with an arc-guiding electrode 8 connected to the arc-guiding fitting 9 and an air pill trigger position, and a side electrode 5 is provided on the side wall of the air pill trigger position; the side electrode 5 is connected to one end of the trigger coil 3 connected, the other end of the trigger coil 3 is connected to the trigger electrode of the arc extinguishing gas pill 4 entering the gas pill trigger position; wherein, the inner wall of the magazine 1 is provided with a top-down The spiral type suspension track 2, and the surface of the arc extinguishing gas pill 4 placed inside the storage magazine 1 is provided with a groove suitable for the su...

Embodiment 2

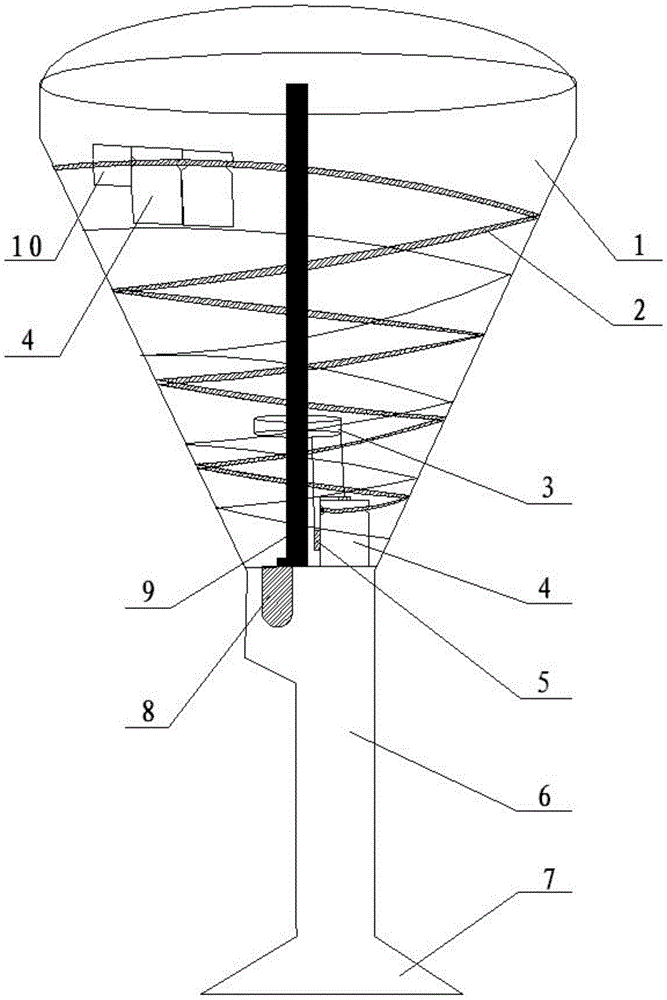

[0032] Such as figure 2As shown, a track-sliding arc extinguishing device includes a magazine storage bin 1 and an arc extinguishing cylinder 6; inside the magazine storage bin 1, a trigger coil 3 and an arc-guiding fitting 9 passing through the trigger coil 3 are arranged, and the storage The bottom of the magazine 1 is provided with an arc-guiding electrode 8 connected with an arc-guiding fitting 9 and an air pill trigger position, and a side electrode 5 is provided on the side wall of the air pill trigger position; the side electrode 5 is connected to one end of the trigger coil 3 connected, the other end of the trigger coil 3 is connected to the trigger electrode of the arc-extinguishing gas pill 4 entering the trigger position of the gas pill; wherein, the inner wall of the magazine storage bin 1 is provided with a top-down mechanism for carrying the arc-extinguishing gas pill 4 The spiral type suspension track 2, and the surface of the arc extinguishing gas pill 4 place...

Embodiment 3

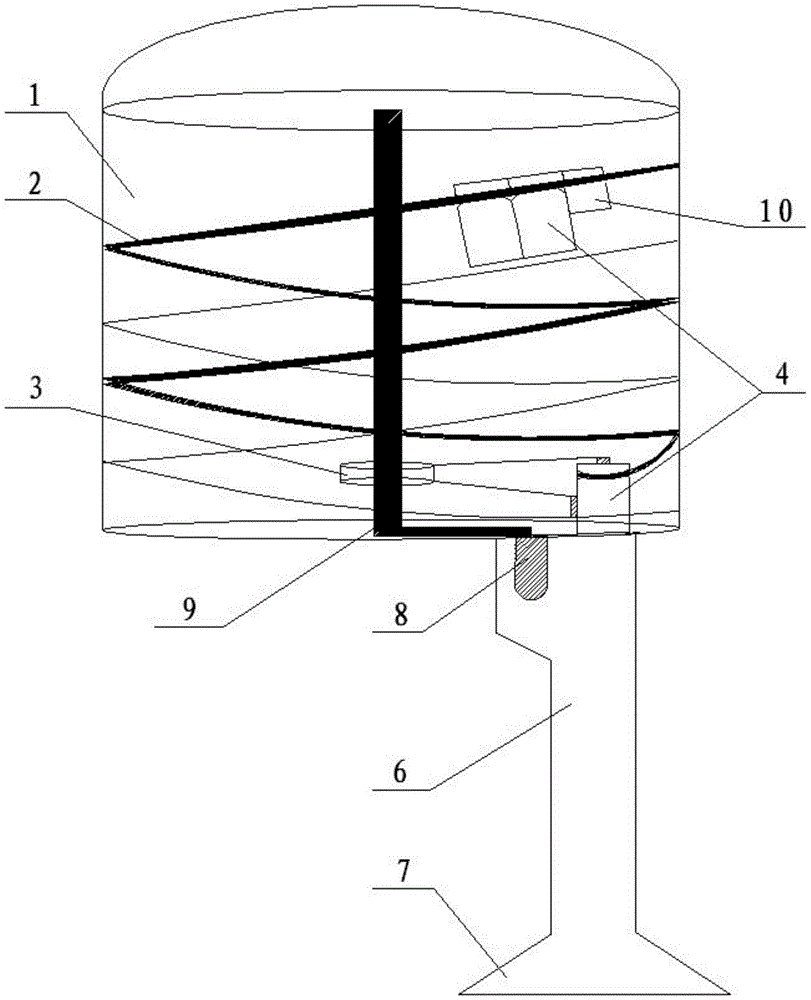

[0036] The difference between this embodiment and embodiment 2 is only: as image 3 As shown, the described magazine storage bin 1 is cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com