Blade assembly system of vegetable cutter

A combined system and vegetable cutting machine technology, applied in the field of kitchen utensils, can solve the problems of heavy workload, easy to cut hands, cumbersome operation, etc., and achieve the effect of prolonging the life of the knife set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

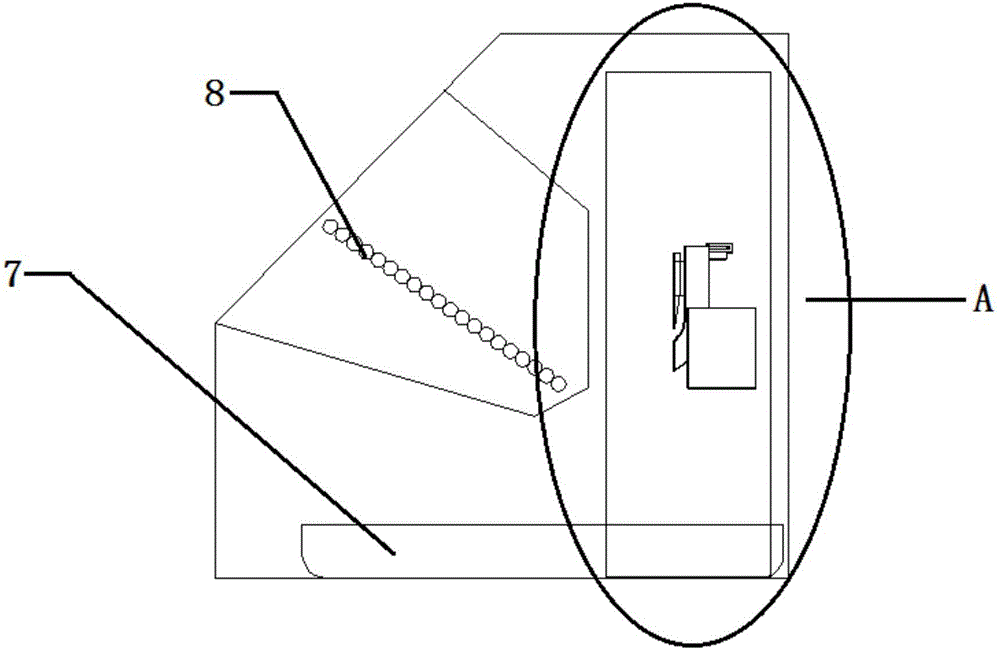

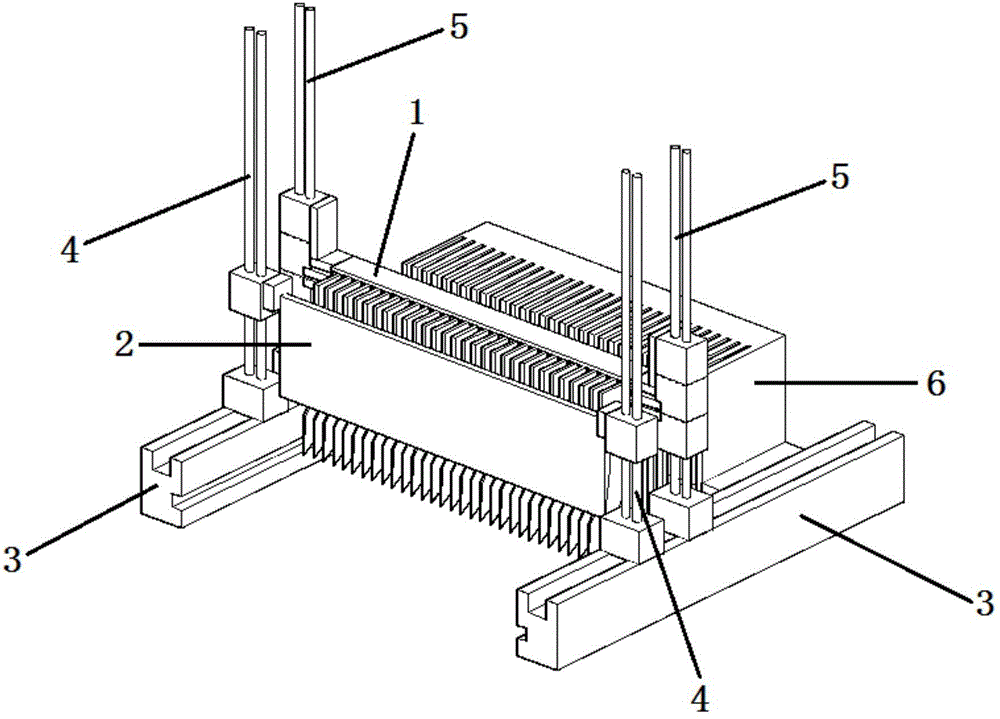

[0029] Such as figure 1 As shown, a blade combination system of a vegetable cutter includes a longitudinal knife set 1, a horizontal blade 2, a horizontal guide rail 3, a vertical guide rail I4, a vertical guide rail II5, a barrier 6, a tray 7 and a roller slope 8.

[0030] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the longitudinal knife set 1 is composed of a longitudinal blade 101 and a fastener 102, the longitudinal blade 101 is provided with a clamping plate 1011, and the clamping plate 1011 is inserted into the slot 1021 of the fastener 102 so as to fix the longitudinal blade 101 On the fastener 102; the longitudinal knife group 1 comprises three groups of longitudinal blades 101 altogether, each group is provided with 10~15, and each group of longitudinal blades 101 cooperates with a fastener 102, and three fasteners 102 will vertically The blades 101 are fixed in a certain order to form a longitudinal knife group 1. According to the number an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap