Coconut palm board pressing device capable of automatic feeding

An automatic feeding and pressing device technology, which is applied to household appliances, wood processing appliances, and other household appliances, can solve problems affecting product quality and limited separation of coconut palm boards, so as to ensure product quality and avoid separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

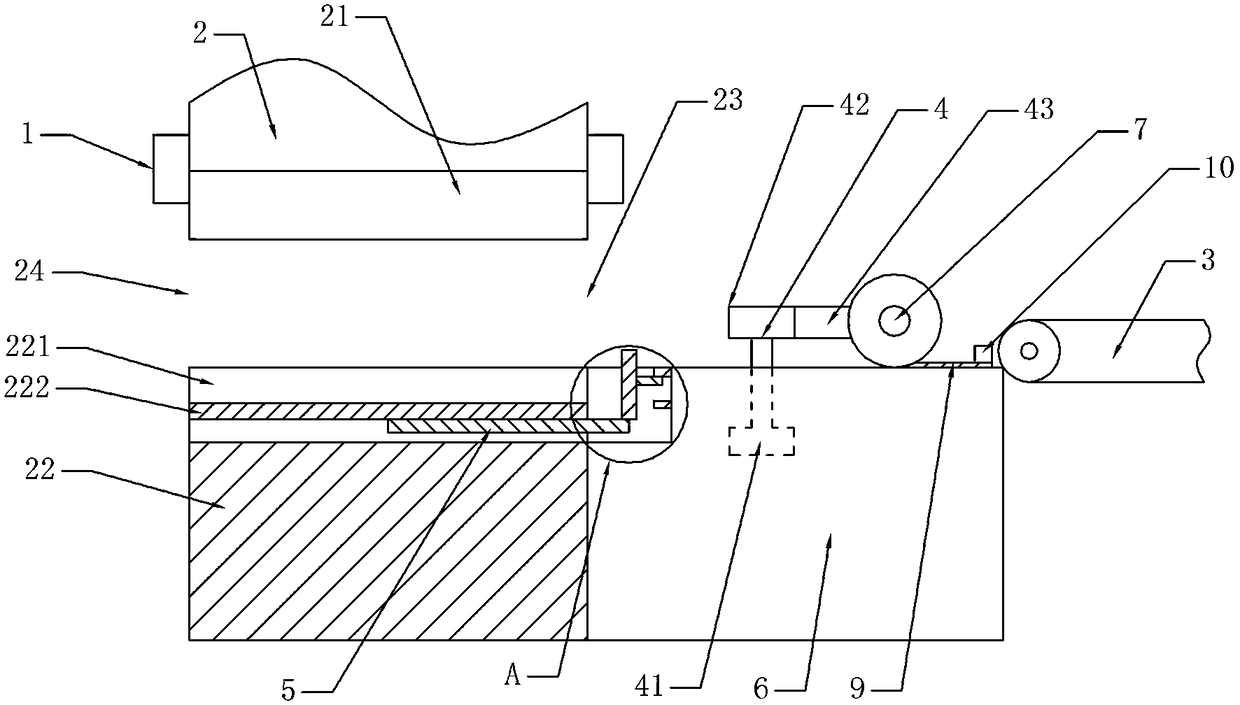

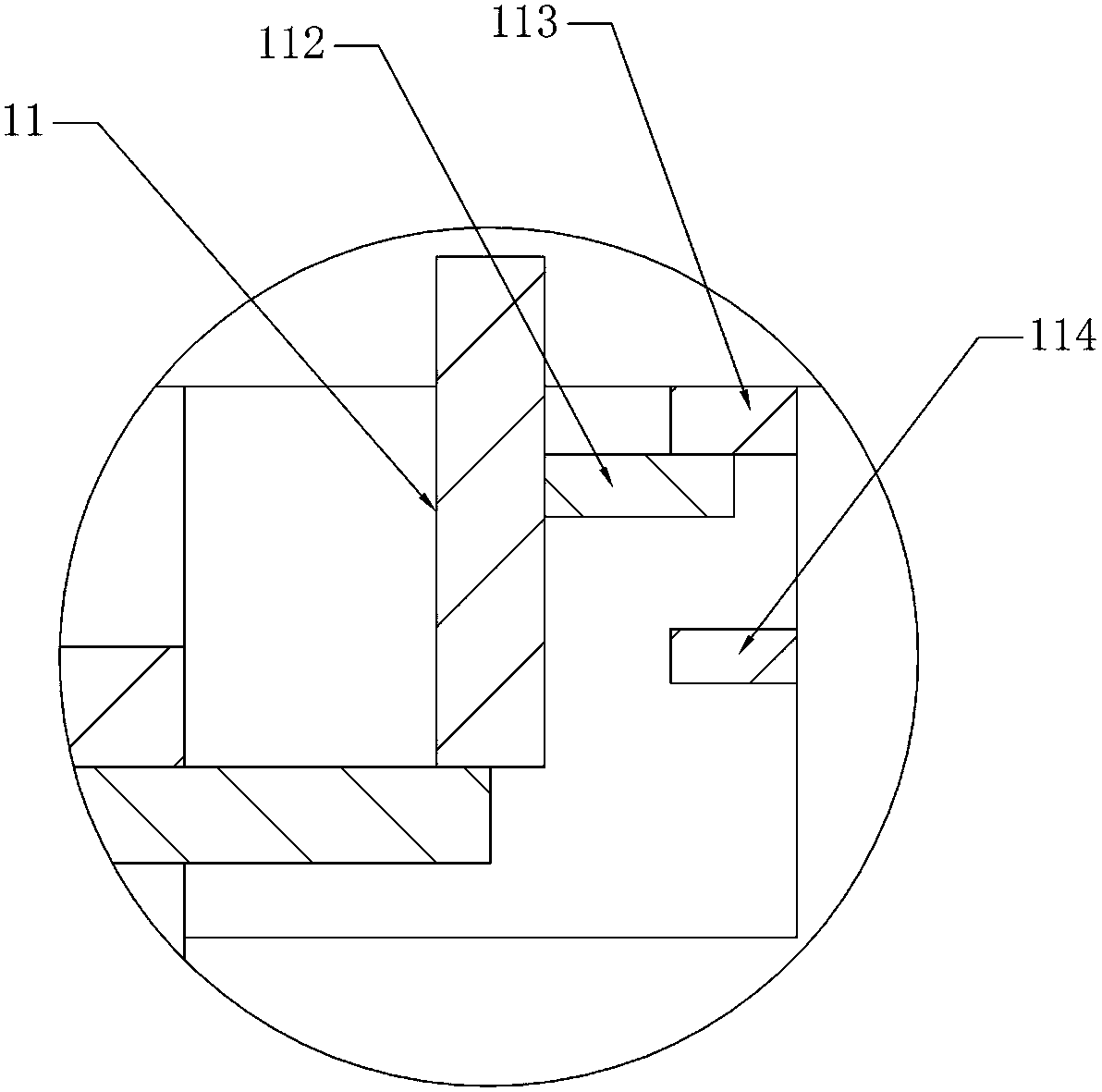

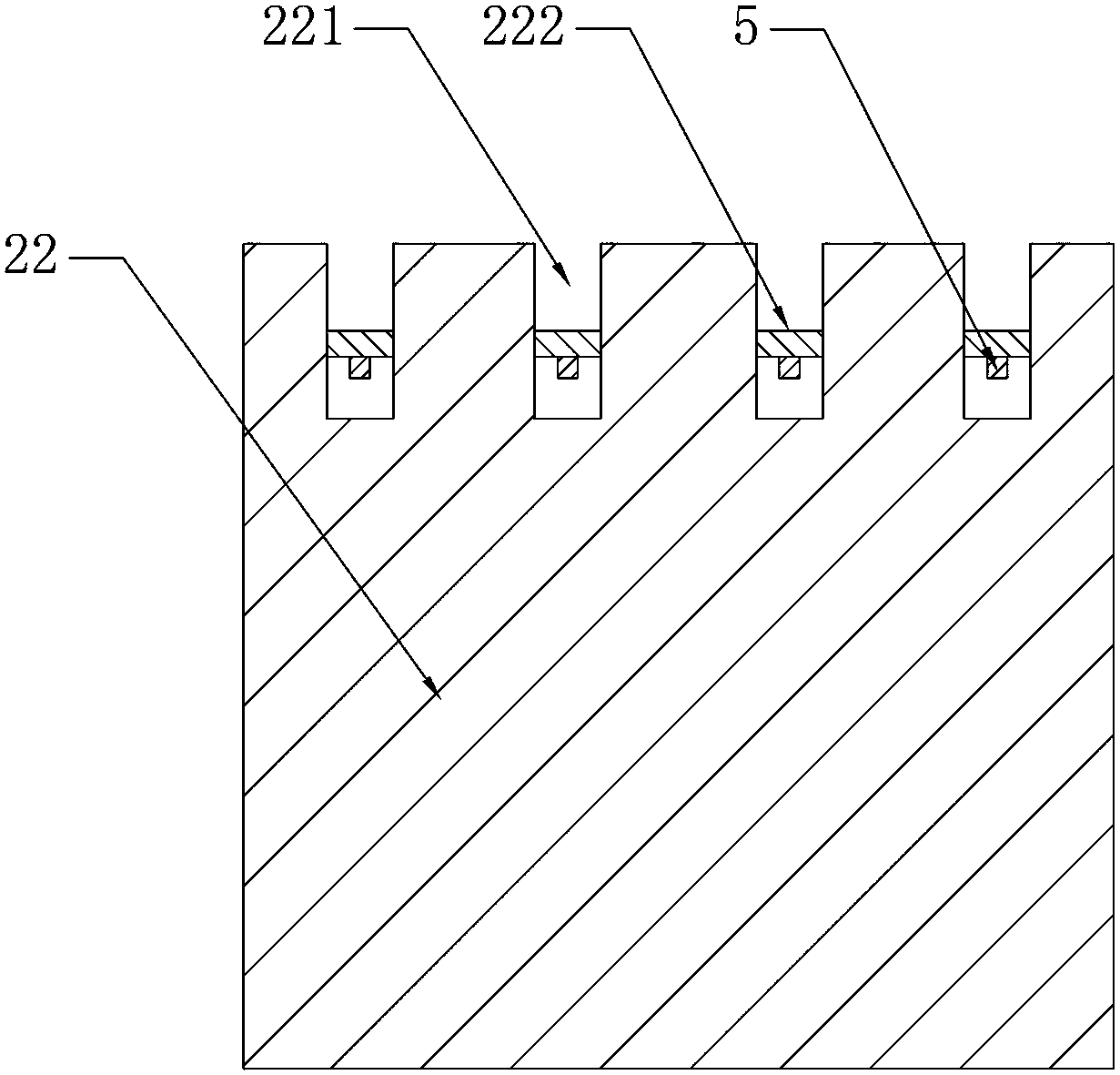

[0021] The reference signs in the accompanying drawings of the description include: frame 1, pressing machine 2, extrusion block 21, storage table 22, groove 221, support plate 222, entrance 23, exit 24, conveyor belt 3, translation equipment 4, the second Two rotating motors 41, gears 42, racks 43, connecting rods 5, platforms 6, rollers 7, first rotating motors 8, load chains 9, first push switches 10, first moving ends 101, first static ends 102 , the second push switch 11 , the second movable end 112 , the second static end 113 , the third static end 114 , and the guide rail 12 .

[0022] This example figure 1 Shown, the coconut palm board laminating device that can automatically feed comprises frame 1 and laminating machine 2, and laminating machine 2 comprises the extruding block 21 of top and the storage table 22 of lower part, extruding block 21 and frame 1 swip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com