Single-drive electric forklift truck frame

A single-drive electric fork and frame technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of reduced maximum load, difficulty in meeting small businesses, and easy rollover, etc., to reduce the total weight of the frame , Improve the effect of longitudinal stability and lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation of the present invention.

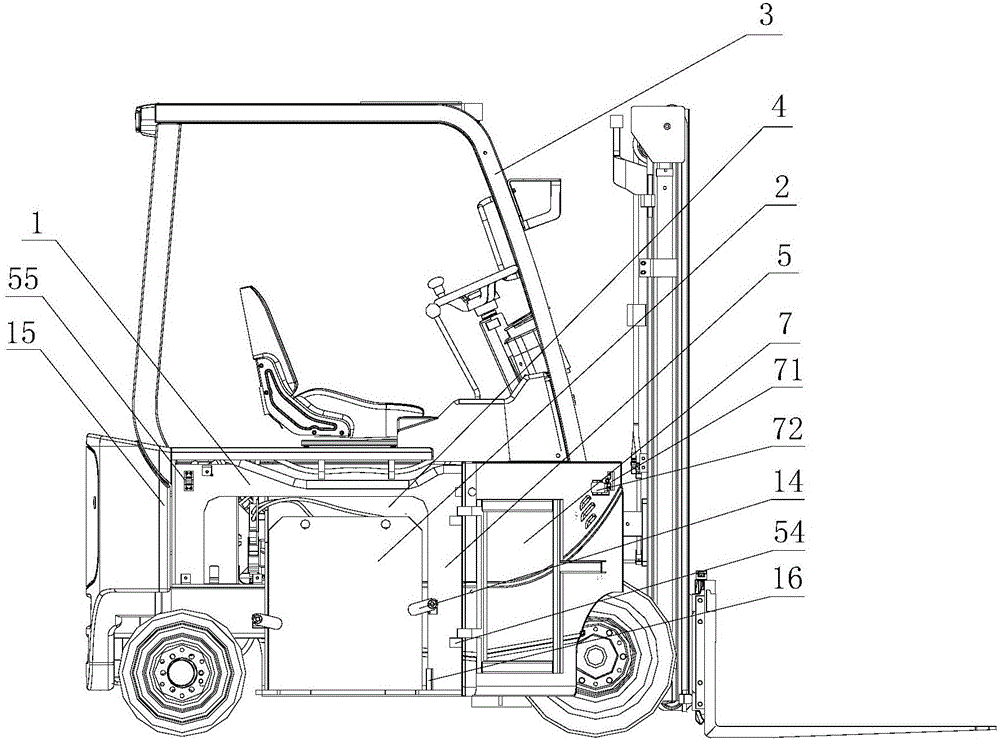

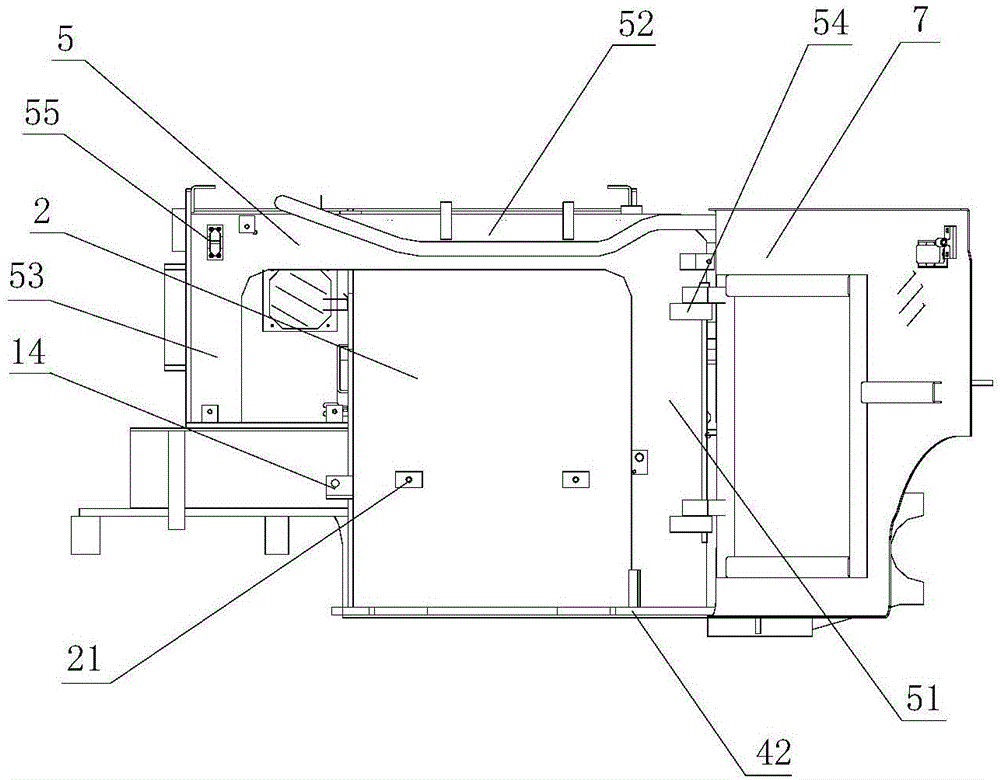

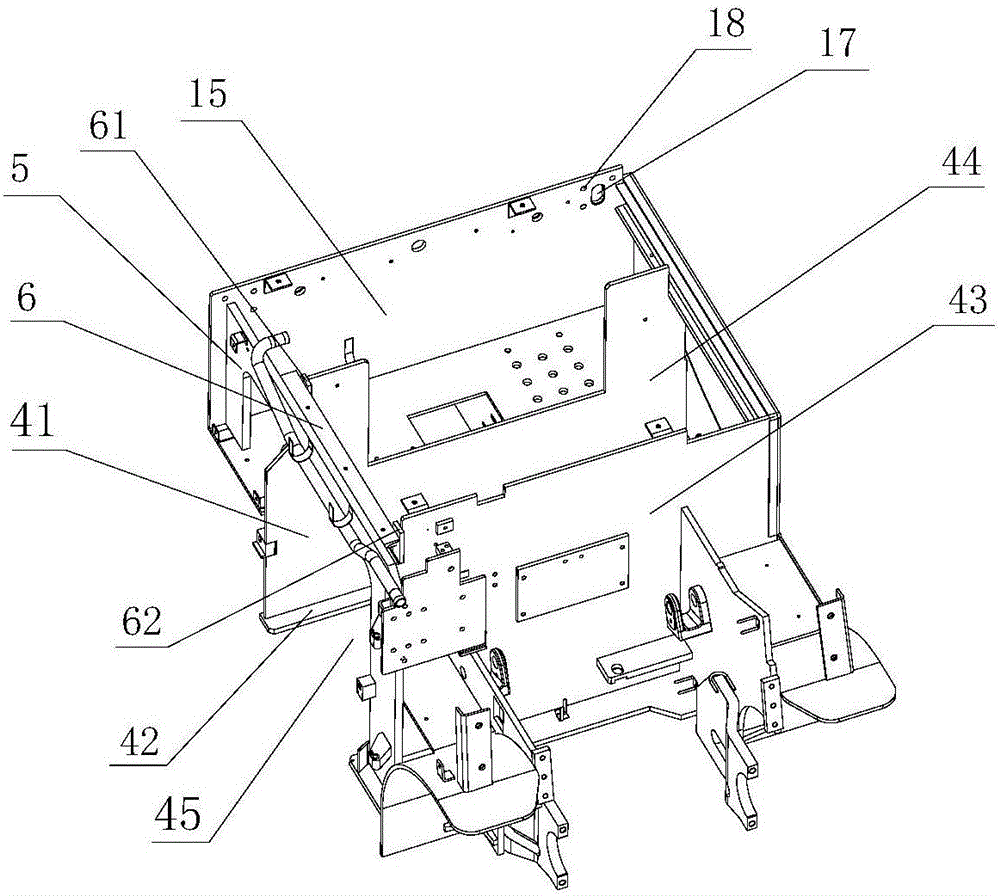

[0027] like Figure 1-Figure 4 As shown, the electric forklift includes an electric forklift frame, a battery 2 and a roof guard 3 fixed on the frame main body 1 . A single-drive electric forklift frame, mainly including a frame body 1, a cavity 4 for placing a battery 2 and opening on one side is arranged inside the frame body 1, and a hole communicating with the cavity 4 is provided on the bottom plate of the cavity 4 There is a gap 45, and symmetrical shelves 42 for supporting the battery 2 are reserved on the front and rear sides of the bottom plate of the cavity 4. The gap 45 is on the same side as the opening 41 of the cavity, and the frame body 1 is close to the opening of the cavity. The left and right sides of place 41 are axially connected with battery stoppers 14, and the vehicle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com