A power distribution method for a vehicle driven by an in-wheel motor

A hub motor and distribution method technology, applied in electric vehicles, control drives, vehicle components, etc., can solve problems such as disordered motor efficiency maps, complex efficiency functions that do not have universal applicability, and look-up table methods that cannot be used to avoid Effects of functional overlap and structural interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

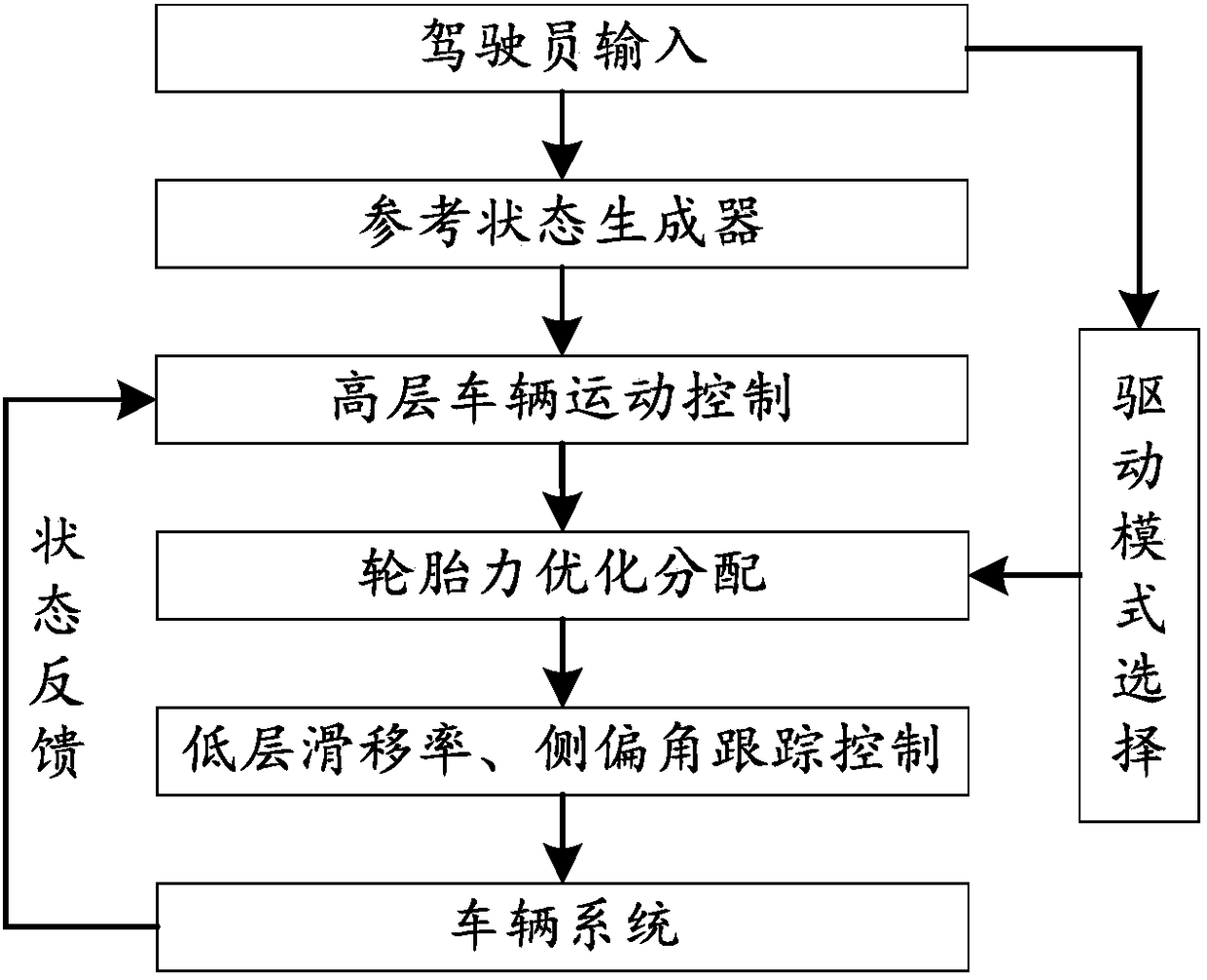

[0058] The present invention provides a method for dynamic distribution of in-wheel motor-driven vehicles, as shown in the attached figure 1 As shown, it specifically includes the following steps:

[0059] 1).According to the steering wheel angle and acceleration / brake pedal signal command input by the driver, analyze the reference state value of the vehicle and complete the drive mode selection;

[0060] 2). By comparing the actual state value of the vehicle with the reference state value, the nonlinear sliding mode control is used to obtain the generalized control force and moment to ensure that the vehicle tracks the reference state value;

[0061] 3). Based on the selected driving mode, road surface adhesion conditions and actuator constraints, the generalized control force / torque required by the vehicle is optimally distributed to each wheel, and the vehicle reference state value is tracked;

[0062] 4). According to the dynamic model of wheel rotation, the sliding mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com